Scrap iron conveying device

A technology of conveying device and iron filings, applied in the direction of conveyor, transportation and packaging, which can solve problems such as conveyor belt burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

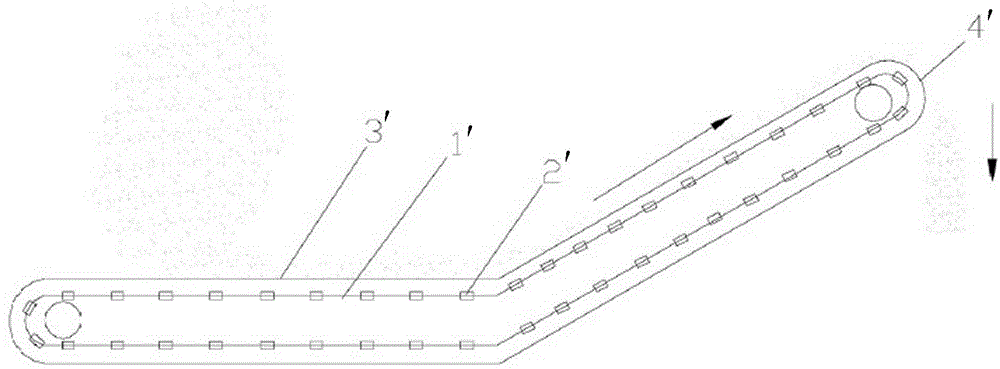

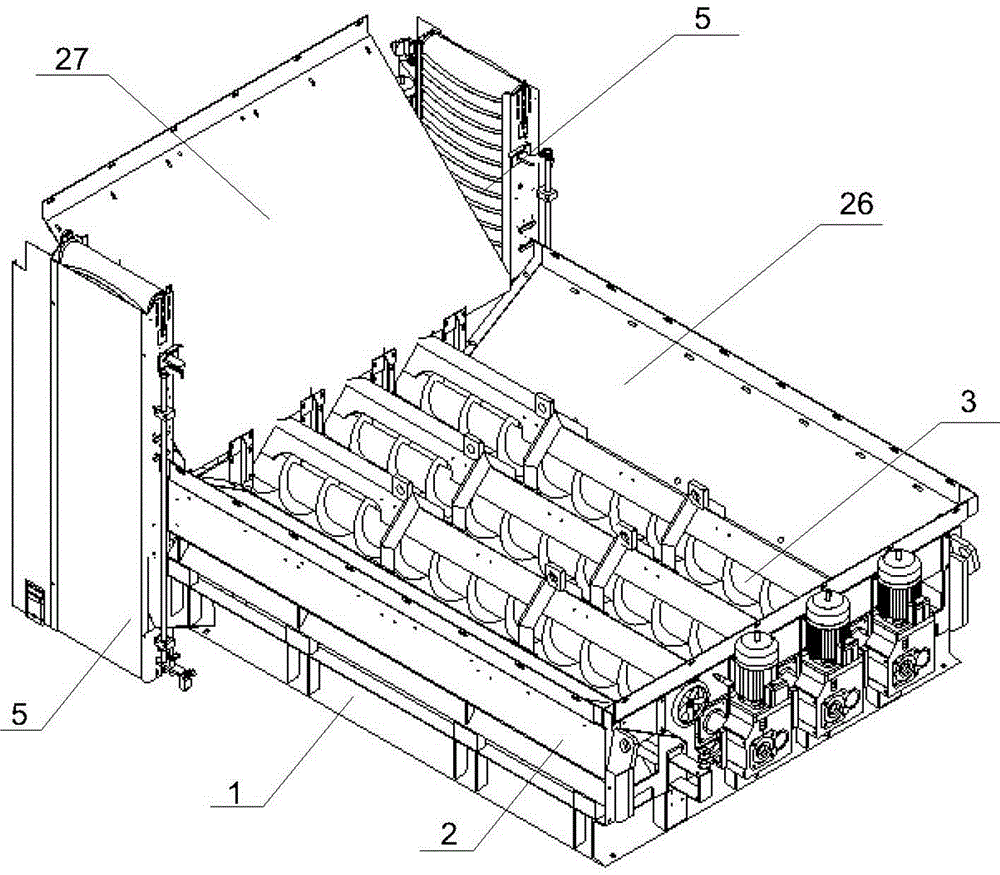

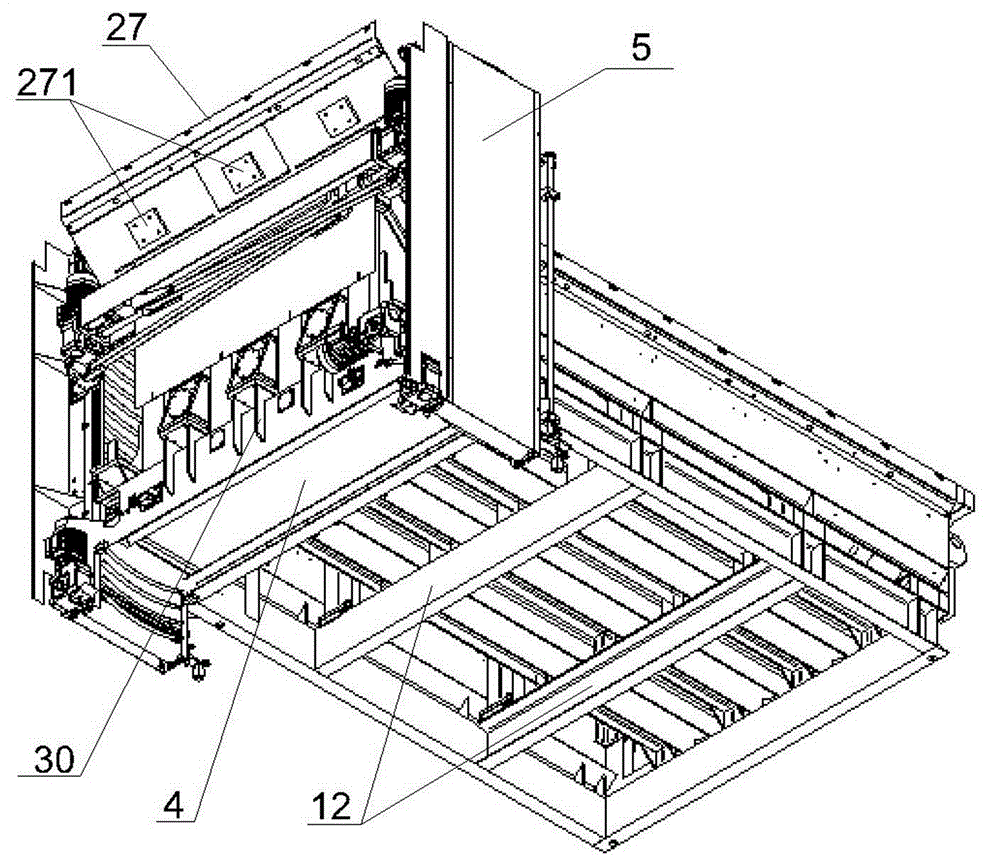

[0068] Example 1.1 : Figure 2-Figure 3 It is a schematic diagram of the overall structure of a preferred embodiment of the iron filings conveying device according to the present invention. In this embodiment, the iron filings conveying device includes a base 1, and the top of the base 1 is connected to the bottom 2 of the iron filings bin, and the bottom 2 of the iron filings bin is equipped with There are three screw conveyors 3, and the rear end of the base 1 is connected with a horizontal discharge belt 4, so that the iron filings in the screw conveyor 3 can enter it. The horizontal discharge belt 4 is arranged perpendicular to the axis of the screw conveyor 3, and the horizontal direction The discharge belt 4 and the screw conveyor 3 are located in the same horizontal plane, the rear end outside the base 1 and the bottom of the iron filings bin 2 is connected to the lateral discharge belt 5, and the lateral discharge belt 5 is located at the same level as the base 1 and ...

Embodiment 12

[0104] Example 1.2 , The chip conveying device is the same as that in Example 1.1, except that the arc value of the scraping strip on the conveyor belt is 30°.

Embodiment 13

[0105] Example 1.3 , The iron chip conveying device is the same as that in embodiment 1.1, except that the arc value of the scraping strip on the conveyor belt is 25°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com