A method of recovering sulfur slag and pyrite to make acid

A technology for producing sulfuric acid and pyrite, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of boiling furnace scarring and other problems, and achieve the effect of being easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

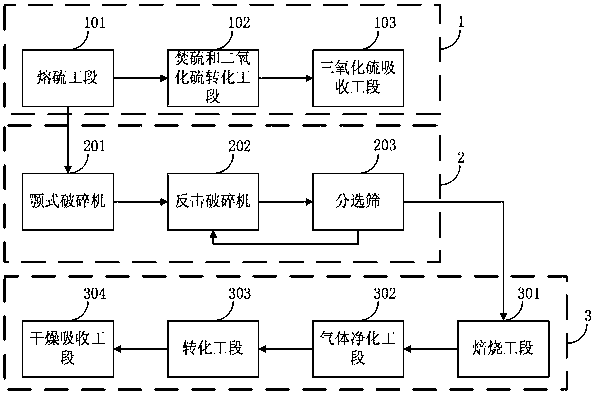

Image

Examples

Embodiment 1

[0045] Sulfur, a by-product of petroleum refining with a sulfur content of 99%, is used to melt sulfur at 140°C and filter after completion. The filter residue and sulfur sand with a sulfur content of 38% are mixed at a mass ratio of 1:4 and sent to the jaw type together. Crusher for primary crushing. After crushing, it is sent to impact crusher for fine crushing. After crushing, it is sent to sorting screen. The particle size is less than 5mm and sent to fluidized furnace. The boiling furnace reacts with air at about 900°C to produce sulfur dioxide, and the sulfur dioxide gas is dedusted, purified, transformed and absorbed to obtain sulfuric acid.

[0046] Specifically, this method has better economic benefits, and the theoretical calculation is as follows:

[0047] The sulfuric acid plant has consumed 43.53wt of sulfur since its start-up, and the cumulative amount of sulfur slag piled up is 2813.28t. Using this data, it can be calculated that the average production of sulfu...

Embodiment 2

[0054] Embodiment 2 carries out experiments on various conditions, and its method for making acid is basically the same as in Example 1, except that the proportioning of sulfur slag and pyrite is different (by mass ratio): Processing 1: sulfur slag and pyrite The ore is mixed in 1:2, treatment 2: sulfur slag and pyrite are mixed in 1:3, treatment 3: sulfur slag and pyrite are mixed in 3:8, treatment 4: sulfur slag and pyrite are mixed in 1:4 Mixing, treatment 5: sulfur slag and pyrite mixed in 2:9, treatment 6: sulfur slag and pyrite mixed in 1:5, treatment 7: sulfur and pyrite mixed in 1:4, treatment 8: sulfur Iron ore, processing 9: sulfur and pyrite mixed at 1:13, processing 10: sulfur. The statistical cycle of fluidized fluidized furnace scarring is one week, and there are twelve cycles in total. The roasting process is divided into two shifts. The roasting process is operated according to the roasting post regulations (pay attention to removing hidden dangers of scarring)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com