A method of manufacturing glazed tiles with a frosted surface

A manufacturing method and technology for glazed tiles are applied in the field of glazed tile manufacturing to achieve the effects of low manufacturing cost, rich product categories and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

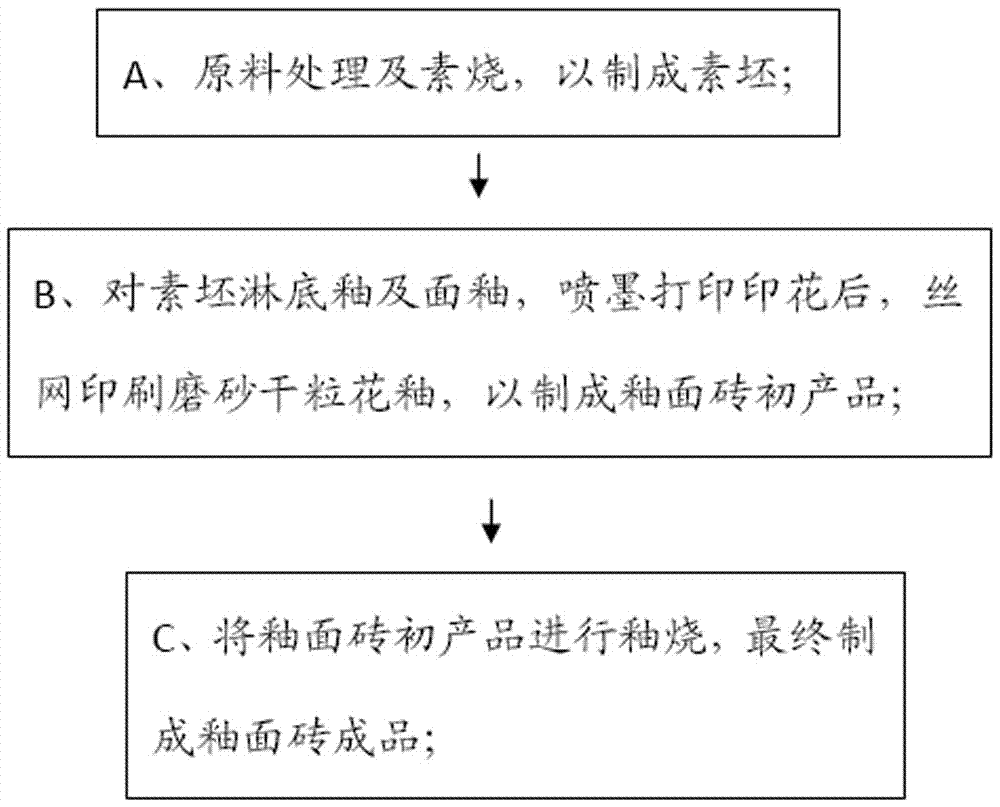

Method used

Image

Examples

Embodiment 1

[0037]First, add 35% by weight of quartz, 15% by weight of feldspar, and 5% by weight of hard clay to 25% by weight of plastic clay, stir evenly, and then add 20% by weight of lime powder Mix evenly, then ball mill to remove iron, the fineness reaches 250 mesh sieve: 2.0%. Then, the powder material with a moisture content of 4 to 5% is formed through spray drying and other processes, and is molded into a biscuit kiln by a press with a pressure of 320 bar. The biscuit after biscuit firing is ready for use.

[0038] The raw materials such as frosted dry granules, water and printing paste are mixed according to the formula ratio of 55%: 10%: 35% (weight percentage), and are ground by a high-speed grinder to make frosted dry granulated floral glaze for later use. Wherein frosted dry grain comprises (weight percentage): SiO 2 : 52.66%, Al 2 o 3 : 20.31%, Fe 2 o 3 : 0.15%, TiO 2 : 0.05%, CaO: 11.57%, MgO: 0.93%, K 2 O: 2.65%, Na 2 O: 4.04%, ZnO: 3.44%, SrO: 3.04%, B 2 o 3...

Embodiment 2

[0041] First, add 35% by weight of quartz, 15% by weight of feldspar, and 5% by weight of hard clay to 25% by weight of plastic clay, stir evenly, and then add 20% by weight of lime powder Mix evenly, then ball mill to remove iron, the fineness reaches 250 mesh sieve: 2.0%. Then, the powder material with a moisture content of 4 to 5% is formed through spray drying and other processes, and is molded into a biscuit kiln by a press with a pressure of 320 bar. The biscuit after biscuit firing is ready for use.

[0042] The raw materials such as frosted dry granules, water and printing paste are mixed according to the formula ratio of 55%: 10%: 35% (weight percentage), and are ground by a high-speed grinder to make frosted dry granulated floral glaze for later use. Wherein frosted dry grain comprises (weight percentage): SiO 2 : 52.66%, Al 2 o 3 : 20.31%, Fe 2 o 3 : 0.15%, TiO 2 : 0.05%, CaO: 11.57%, MgO: 0.93%, K 2 O: 2.65%, Na 2 O: 4.04%, ZnO: 3.44%, SrO: 3.04%, B 2 o ...

Embodiment 3

[0045] First, add 35% by weight of quartz, 15% by weight of feldspar, and 5% by weight of hard clay to 25% by weight of plastic clay, stir evenly, and then add 20% by weight of lime powder Mix evenly, then ball mill to remove iron, the fineness reaches 250 mesh sieve: 2.0%. Then, the powder material with a moisture content of 4 to 5% is formed through spray drying and other processes, and is molded into a biscuit kiln by a press with a pressure of 320 bar. The biscuit after biscuit firing is ready for use.

[0046] The raw materials such as frosted dry granules, water and printing paste are mixed according to the formula ratio of 55%: 10%: 35% (weight percentage), and are ground by a high-speed grinder to make frosted dry granulated floral glaze for later use. Wherein frosted dry grain comprises (weight percentage): SiO 2 : 52.66%, Al 2 o 3 : 20.31%, Fe 2 o 3 : 0.15%, TiO 2 : 0.05%, CaO: 11.57%, MgO: 0.93%, K 2 O: 2.65%, Na 2 O: 4.04%, ZnO: 3.44%, SrO: 3.04%, B 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com