A method for producing illite powder from illite clay ore

A technology of illite powder and illite, which is applied in chemical instruments and methods, solid separation, inorganic chemistry, etc., can solve the problems of raw material waste, illite cannot be washed, and production cannot be carried out, and achieves strong process continuity and improved Enterprise production income, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

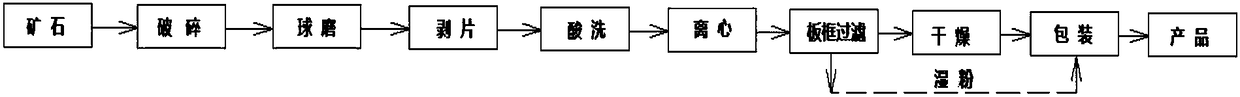

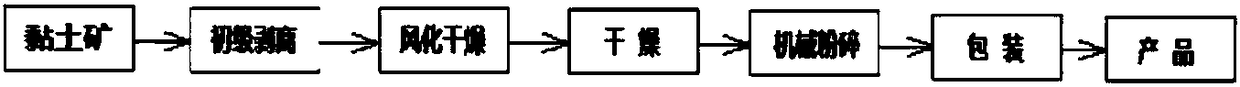

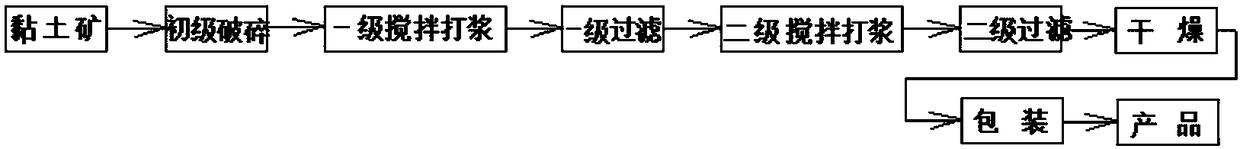

[0027] The first step in the development and utilization of illite is to extract illite from illite clay ore. Such as Figure 4 As shown, after testing, the illite content in the clay mine is 40% to 45%, and the rest is impurities such as stones and silicates. When the ore soil is first mined, the water content is relatively large, and the viscosity is relatively high, because it contains stones, and the hardness is also relatively high. The technological process of the present invention is that the illite clay ore is excavated from the mine with an excavator and transported to the milling factory, and then loaded into a hydraulic beater by a forklift, and the clay ore is crushed under the action of high-pressure water, and the large-grained quartz , carbonate and other impurities are isolated by the beater, and small particles of illite and quartz enter the water to become illite slurry. The slurry is pumped out. According to the purpose and needs of the powder, the slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com