A kind of preparation method of tetracycline hydrochloride

A technology of tetracycline hydrochloride and tetracycline, which is applied in the preparation of carboxylic acid amides, the preparation of organic compounds, chemical instruments and methods, etc., can solve problems such as increased production costs, urea consumption, yield loss, etc., and achieves reduction of production equipment and personnel. The effect of reducing and lowering production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

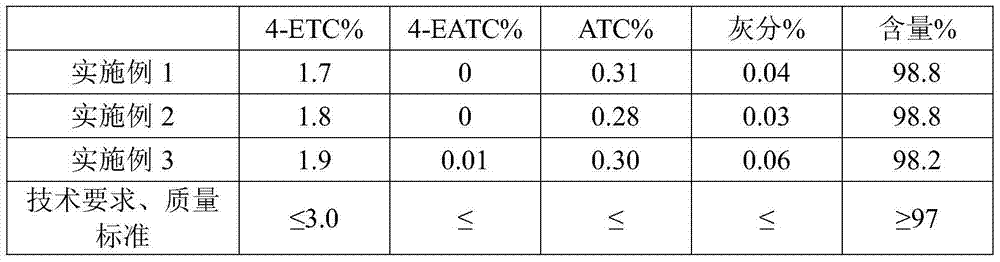

Embodiment 1

[0015] Weigh 100 g of tetracycline wet alkali with a water content of 15%. According to the ratio of tetracycline (dried): butanol = 1:5-6, measure 425ml of butanol at a temperature of 17°C. Mix and stir evenly, adjust with 30ml of concentrated hydrochloric acid, measure the solution with pH test paper in the range of pH=1.7~1.9, the solution is clear, and measure its potency unit to be 154501u / ml. Begin to heat up, with 30 minutes the solution temperature is raised to 51 ℃, continue to keep warm for 60 minutes, the temperature is at 50~52 ℃, then cool down, the temperature is down to 25 ℃, spent 60 minutes. Crystallization is over. The crystallization liquid is extracted in vacuum, washed with 120ml of acetone, drained, the tetracycline hydrochloride wet product after the extraction is put into an oven for drying, and taken out after 30 minutes to obtain tetracycline hydrochloride 67g, measure its moisture content 0.33%.

Embodiment 2

[0017] Weigh 200g of tetracycline wet alkali with a water content of 15%. According to the ratio of tetracycline (dried): butanol = 1:5-6, measure 850ml of butanol at a temperature of 17.5°C. Mix and stir evenly, adjust with 58ml of concentrated hydrochloric acid, measure the solution with pH test paper in the range of pH=1.7~1.9, the solution is clear, and measure its potency unit to be 162546u / ml. Begin to heat up, with 35 minutes solution temperature is raised to 50 ℃, continue to keep warm for 60 minutes, temperature is at 50~52 ℃, then cool down, temperature is down to 25 ℃, spent 60 minutes. Crystallization is over. The crystallization liquid is extracted in vacuum, washed with 240ml of acetone, drained, the tetracycline hydrochloride wet product after the extraction is put into an oven for drying, and taken out after 30 minutes to obtain tetracycline hydrochloride 131g, measure its moisture content 0.24%.

Embodiment 3

[0019] Weigh 1000 g of tetracycline wet alkali with a water content of 15%. According to the ratio of tetracycline (dried): butanol = 1:5-6, measure 4250ml of butanol at a temperature of 19°C. Mix and stir evenly, adjust with 290ml of concentrated hydrochloric acid, measure the solution with pH test paper in the scope of pH=1.7~1.9, the solution is clear, measure its potency unit to be 1491051u / ml. Begin to heat up, with 30 minutes the solution temperature is raised to 51 ℃, continue to keep warm for 60 minutes, the temperature is at 50~52 ℃, then cool down, the temperature is down to 25 ℃, spent 60 minutes. Crystallization is over. The crystallization liquid is extracted in vacuum, washed with acetone of 1200ml, drained, the tetracycline hydrochloride wet product after the extraction is put into an oven for drying, takes out after 30 minutes, weighs tetracycline hydrochloride 663g, measures its moisture content 0.41%.

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com