Filtering method for tetracycline fermentation liquor

A filtration method and fermentation liquid technology, applied in the field of biology and medicine, can solve the problems of easy degradation of tetracycline, inability to filter, high labor intensity, etc., improve labor intensity and working environment, reduce the probability of degradation reaction, and the degree of automation Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

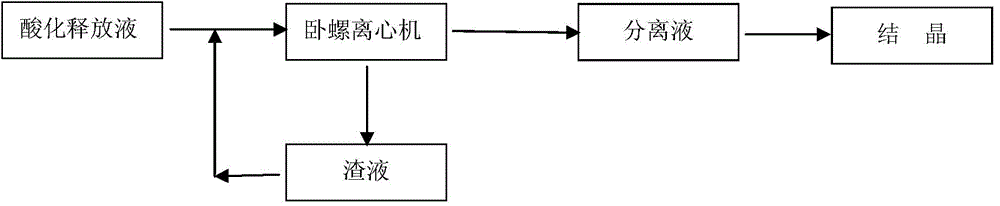

Embodiment 1

[0013] Take 1L of tetracycline fermentation broth, measure its titer unit as 30150u / ml, add 1.6L of drinking water, dilute the fermented broth titer unit to 12000u / ml, stir well and cool down to 14°C, add 60g of oxalic acid to adjust the pH of the diluted solution =1.8, then add 5.0g of yellow blood salt, 4.0g of zinc sulfate, 1.5g of borax and other purifying agents in turn for purification treatment, and then separate with a decanter centrifuge to obtain 1.80L of separation liquid and 0.8L of slag liquid. Dilute 0.8L of slag liquid with 1.2L of oxalic acid water with pH=1.8, stir for 30 minutes at a temperature of 14°C, and separate with a decanter centrifuge to obtain 1.4L of separated liquid and 0.6L of slag liquid. Then dilute 0.6L of slag liquid with 2.4L of oxalic acid water with pH 1.8, stir for 30 minutes at a temperature of 14°C, and separate with a decanter centrifuge to obtain 2.0L of separated liquid and 1.0L of slag liquid. The slag liquid was treated repeatedly ...

Embodiment 2

[0015] Take 2L of tetracycline fermentation broth, measure its titer unit as 32080u / ml, add 2L of drinking water, dilute the fermented broth titer unit to 16000u / ml, stir well and cool down to 13°C, add 118g of oxalic acid to adjust the pH= 1.8, then add 10.0g of yellow blood salt, 9.0g of zinc sulfate, 3.0g of borax and other purifiers in turn for purification treatment, and then separate with a decanter centrifuge to obtain 2.8L of separation liquid and 1.2L of slag liquid. Dilute 1.2L of slag liquid with 2.8L of oxalic acid water with pH=1.9, control the temperature at 14°C, stir for 30 minutes, and separate with a decanter centrifuge to obtain 2.8L of separated liquid and 1.2L of slag liquid. Also dilute 1.2L of slag liquid with 2.8L of oxalic acid water with pH=1.9, control the temperature at 14°C, stir for 30 minutes, and separate with a decanter centrifuge to obtain 2.8L of separated liquid and 1.2L of slag liquid. The slag liquid was treated repeatedly in this way unti...

Embodiment 3

[0017] Take 2L of tetracycline fermentation broth, measure its titer unit as 31009u / ml, add 2L of drinking water, dilute the fermented broth titer unit to 18000u / ml, stir evenly and cool down to 13°C, add 124g of oxalic acid to adjust the pH= 1.6, then add 10.0g of yellow blood salt, 9.0g of zinc sulfate, 3.0g of borax and other purifiers in turn for purification treatment, and then separate with a decanter centrifuge to obtain 2.6L of separation liquid and 1.2L of slag liquid. Dilute 1.2L of slag liquid with 2.8L of oxalic acid water with pH=1.9, control the temperature at 14°C, stir for 30 minutes, and separate with a decanter centrifuge to obtain 2.8L of separated liquid and 1.2L of slag liquid. Also dilute 1.2L of slag liquid with 2.8L of acid water with pH=1.9, control the temperature at 14°C, stir for 30 minutes, and separate with a decanter centrifuge to obtain 2.8L of separated liquid and 1.2L of slag liquid. The slag liquid was treated repeatedly in this way until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com