Spraying film waterproof material for improving spraying film main liquid stability

A spray film waterproof and stable technology, applied in the direction of coating, etc., can solve problems such as self-aggregation, scrapped raw materials, skin allergies, etc., and achieve the effects of reducing costs, improving dispersion, and delaying self-aggregation

Inactive Publication Date: 2016-02-03

SOUTHWEST JIAOTONG UNIV

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it is necessary to add substances containing oxidants to the main solution of the spray film before the construction of the spray film. Due to the high activity of the magnesium acrylate monomer, self-polymerization often occurs, resulting in a large number of scrapped raw materials and blockage of construction pipelines and equipment, which seriously affects the construction. process

Secondly, due t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

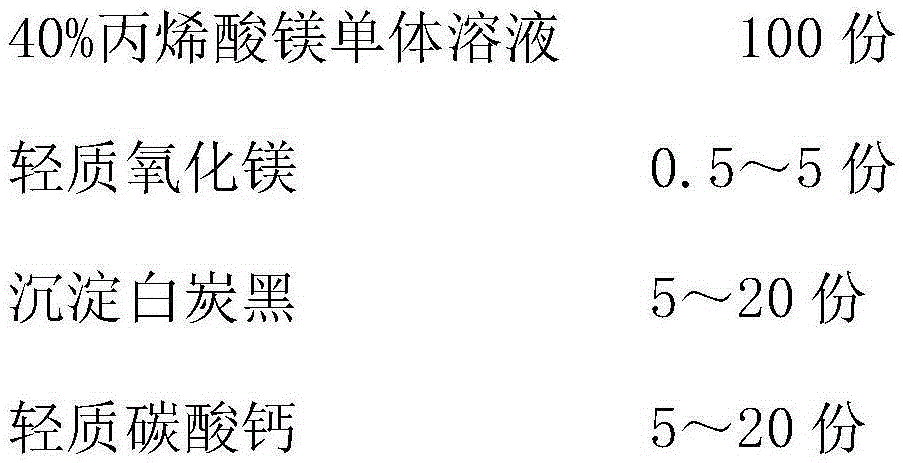

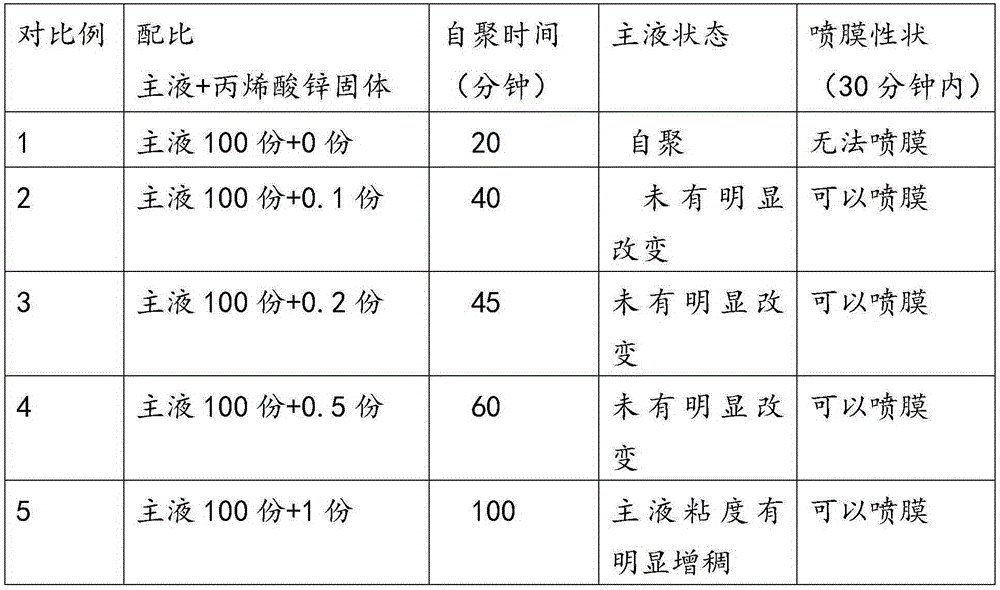

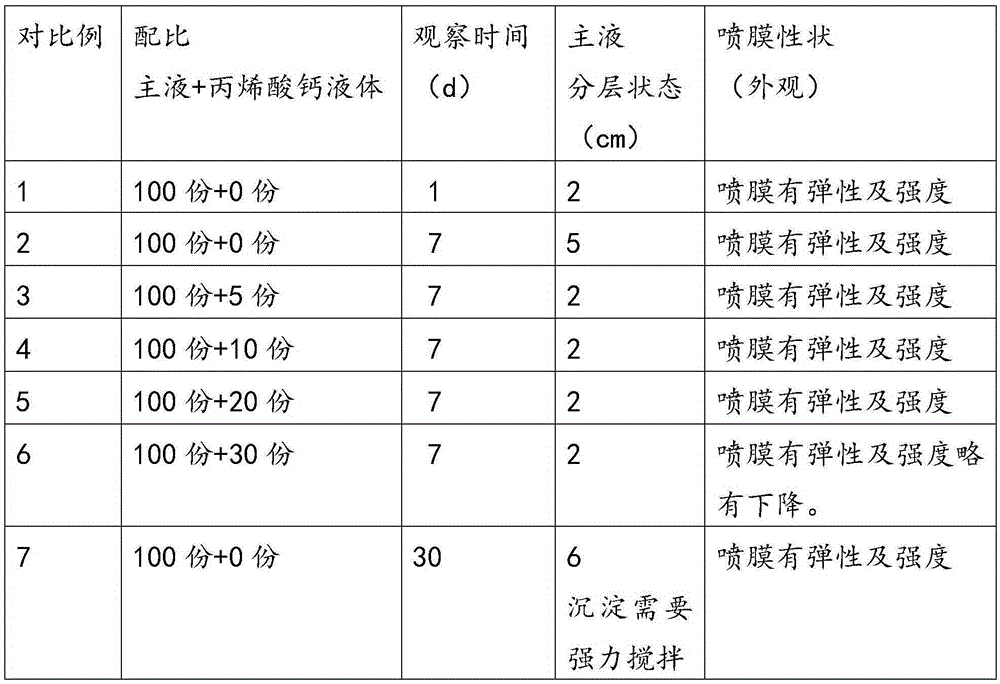

The present invention discloses a spraying film waterproof material for improving spraying film main liquid stability, wherein the components comprise, by weight, a main liquid and acrylates, and specifically comprise, by weight, 100 parts of a main liquid, 5-20 parts of a 30% calcium acrylate liquid, and 0.8-2.0 parts of a zinc acrylate aqueous solution. According to the present invention, the self-polymerization and the agglomeration of the spraying film main liquid can be effectively solved so as to improve the spraying film main liquid stability, ensure the smooth performing of the spraying film construction, and stabilize the mechanical property of the spraying film waterproof material.

Description

technical field [0001] The invention relates to a spray-film waterproof material used in underground engineering, in particular to a main material of the spray-film waterproof material with magnesium acrylate as the main component and a preparation method thereof. Background technique [0002] In the prior art, many patents related to acrylate spray film waterproof materials are disclosed, such as publication number CN1803948, "main material of spray film waterproof material with high tensile strength and its preparation method"; publication number CN101429352, "rapidly polymerizable, etc. Quantitative two-component spray film waterproof material and its preparation method", etc. However, it is necessary to add substances containing oxidants to the main solution of the spray film before the construction of the spray film. Due to the high activity of the magnesium acrylate monomer, self-polymerization often occurs, resulting in a large number of scrapped raw materials and blo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D4/02C09D7/12

Inventor 杨其新盛草樱杨娟刘东民蒋雅君

Owner SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com