A kind of high temperature resistant modified epoxy paint and its preparation method and application

A technology of epoxy paint and high temperature resistance, applied in the field of coatings, can solve the problems of inability to play a protective role, insufficient heat resistance, falling off, etc., and achieve the effects of low production cost, excellent high temperature resistance, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

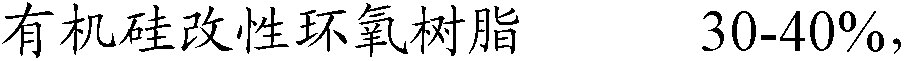

[0060] A high-temperature-resistant modified epoxy paint, comprising main agent A component and curing agent B component, the weight ratio of main agent A component and curing agent B component is 5:1, and the main agent A component includes Each raw material of following mass percentage content:

[0061]

[0062] The B component includes the following raw materials in mass percentages:

[0063] Polyamide curing agent (specifically ARADUR 115-3) 70%,

[0064] Solvent (specifically xylene) 30%.

[0065] The preparation method of high temperature resistant modified epoxy paint in embodiment 1 is as follows:

[0066] (1) Select the raw materials in component A according to the mass percentage, the sum of the mass fractions of each raw material is 100%, disperse the silicone modified epoxy resin and the solvent evenly, and then add the ground talcum powder and mica in turn powder, glass powder, titanium dioxide, zinc phosphate and additives, and stirred at 1000r / min for 20mi...

Embodiment 2

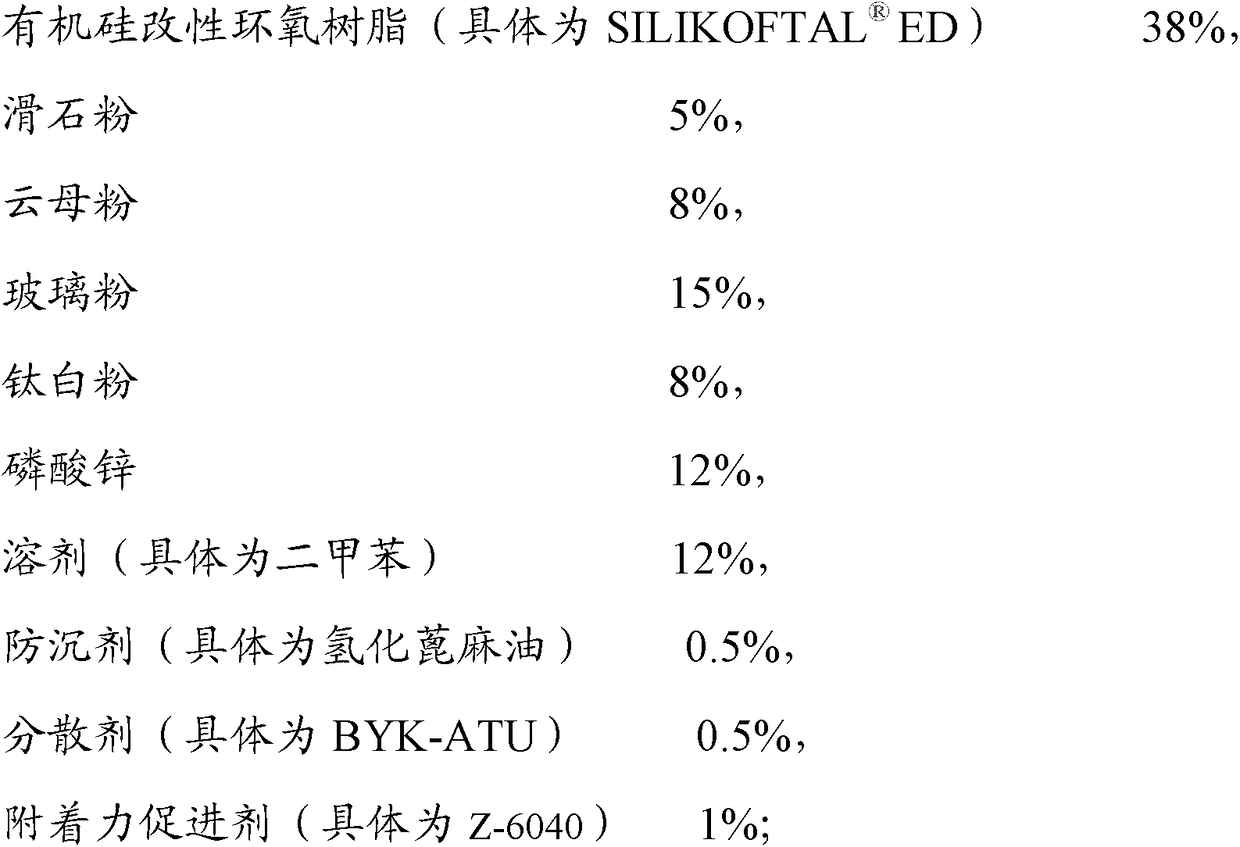

[0070] A high temperature resistant modified epoxy paint, comprising main agent A component and curing agent B component, the weight ratio of main agent A component and curing agent B component is 4:1, and the main agent A component includes Each raw material of following mass percentage content:

[0071]

[0072] The B component includes the following raw materials in mass percentages:

[0073] Polyamide curing agent (specifically ARADUR 115-3) 80%,

[0074] Solvent (specifically xylene) 20%.

[0075] The preparation method of the high temperature resistant modified epoxy paint in embodiment 2 is as follows:

[0076] (1) Select the raw materials in component A according to the mass percentage, the sum of the mass fractions of each raw material is 100%, disperse the silicone modified epoxy resin and the solvent evenly, and then add the ground talcum powder and mica in turn powder, glass powder, titanium dioxide, zinc phosphate and additives, and stirred at 1200r / min for ...

Embodiment 3

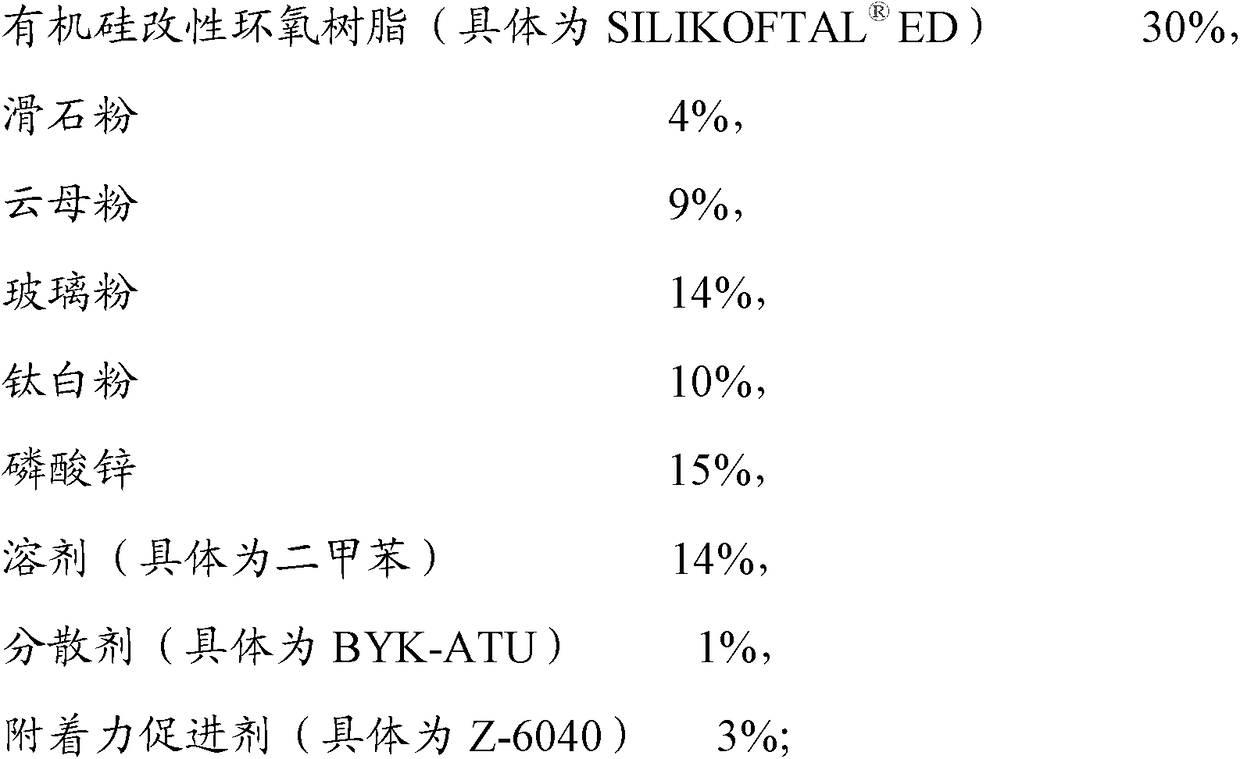

[0080] A high temperature resistant modified epoxy paint, comprising main agent A component and curing agent B component, the weight ratio of main agent A component and curing agent B component is 4:1, and the main agent A component includes Each raw material of following mass percentage content:

[0081]

[0082] The B component includes the following raw materials in mass percentages:

[0083] Polyamide curing agent (specifically ARADUR 115-3) 60%,

[0084] Solvent (specifically xylene) 40%.

[0085] The preparation method of the high temperature resistant modified epoxy paint in embodiment 2 is as follows:

[0086] (1) Select the raw materials in component A according to the mass percentage, the sum of the mass fractions of each raw material is 100%, disperse the silicone modified epoxy resin and the solvent evenly, and then add the ground talcum powder and mica in turn Powder, glass powder, titanium dioxide, zinc phosphate and additives, and stirred at 1100r / min for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com