An optical plastic substrate coating device

A coating device and optical plastic technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of poor film firmness, easy foaming and peeling, etc., and achieve high production efficiency and good quality. The effect of firmness and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

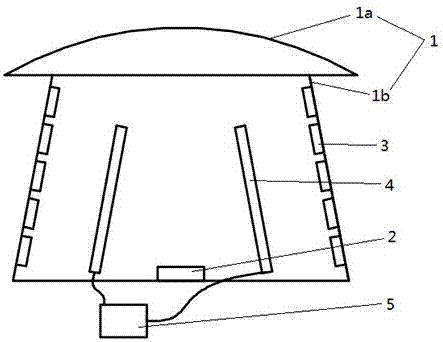

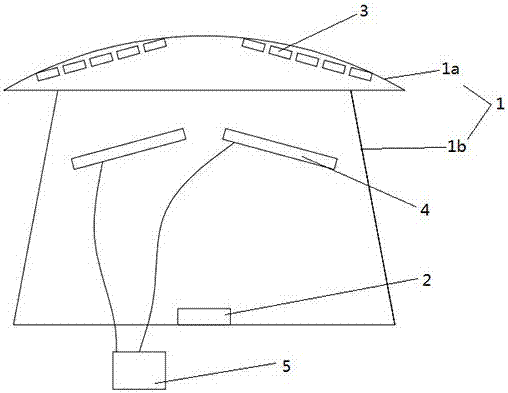

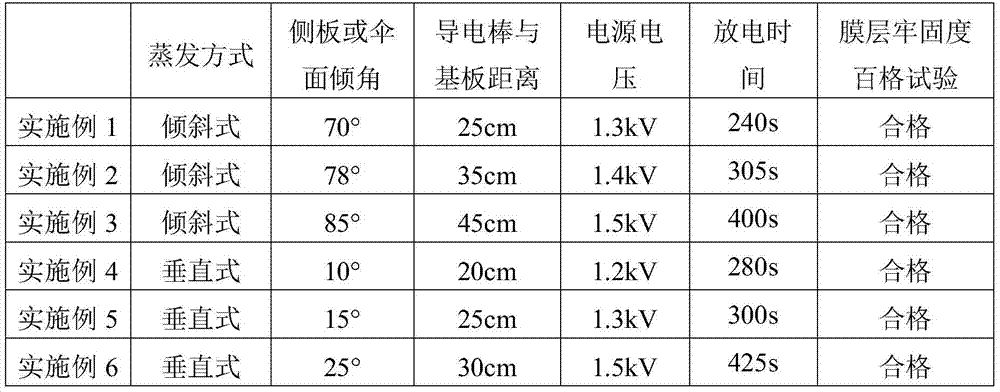

[0014] See figure 1 , the inclined optical plastic substrate coating device of the present embodiment includes a coating umbrella placed in a vacuum furnace, an evaporation source and a conductive rod, the coating umbrella is provided with side plates and umbrella surfaces, and the substrate to be coated is placed on the side plates. The included angle between the side plate and the horizontal is 70-85°, and the evaporation source is arranged at the lower part of the coating umbrella. The conductive rod is an oxygen-free copper rod with a diameter of 10 cm and a length of 1.0 m. The conductive rod is divided into left and right two and fixedly arranged between the plastic substrate and the evaporation source. The angle between the conductive rod and the surface of the plastic substrate is 0-5°, and the distance between the conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com