A bidirectional powder spreading device for 3D printing process

A powder spreading device and 3D printing technology, which is applied in the field of 3D printing, can solve the problems of powder agglomeration and unloading, uncontrollable powder output and powder compaction, and achieve the effect of avoiding powder agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

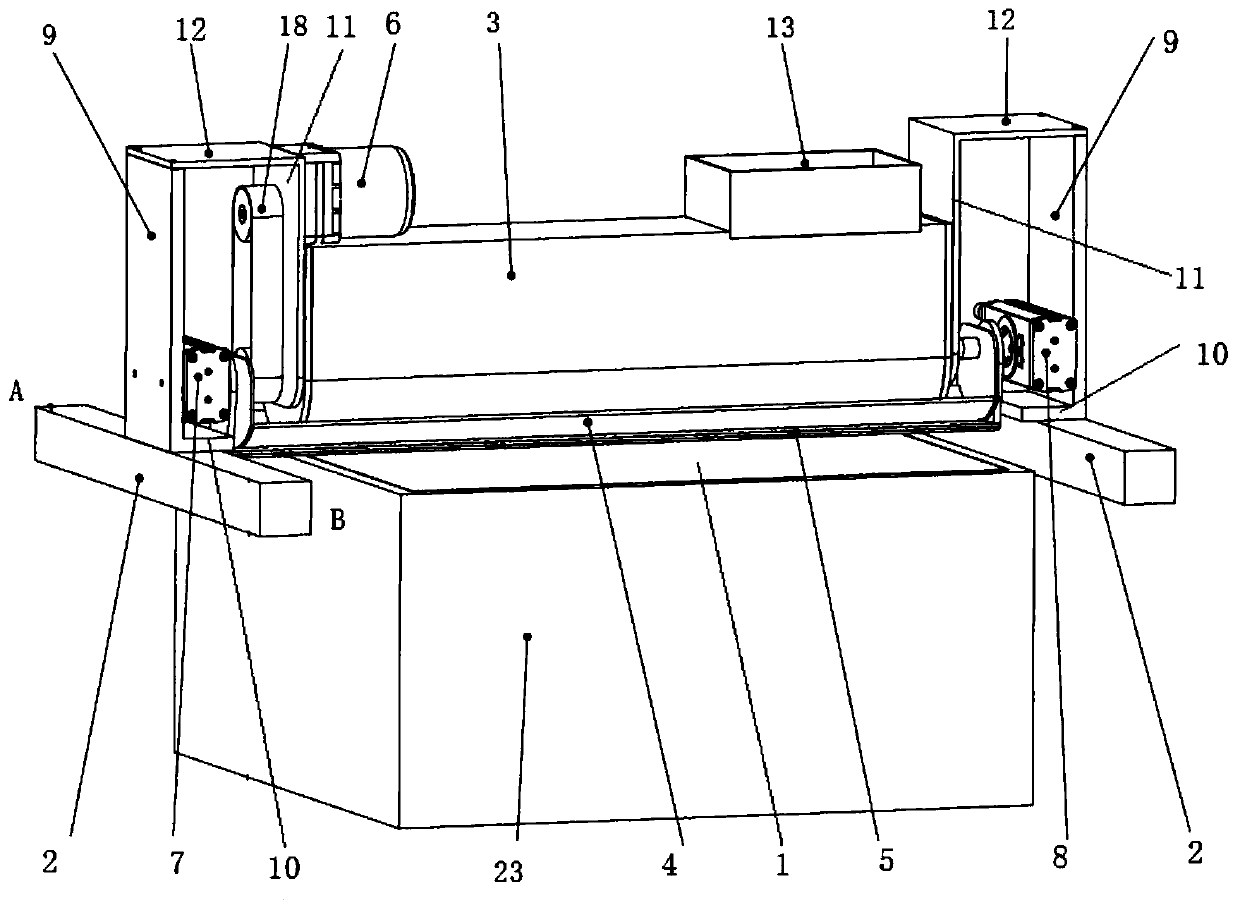

[0032] This embodiment provides a two-way powder spreading device for 3D printing process, such as Figure 1-Figure 2 As shown, it includes two connecting frames, which are one-to-one corresponding to the two guide rails 2 and are slidably connected; the powder container 3, which includes a feed port 13 and a discharge port, and the left and right sides of the powder container 3 are connected to the two The connecting frames are one-to-one corresponding and fixedly connected; the blanking plate 4 is rotatably arranged on the outside of the powder container 3 to open and close the discharge port; the scraper 5 for smoothing the powder is rotatably arranged On the outside of the powder container 3, to control the compactness of the powder; the stirring device, which is rotatably arranged inside the powder container 3, to break up and transport the powder; the first power unit, which is connected with the stirring device The transmission is connected to drive the stirring device ...

Embodiment 2

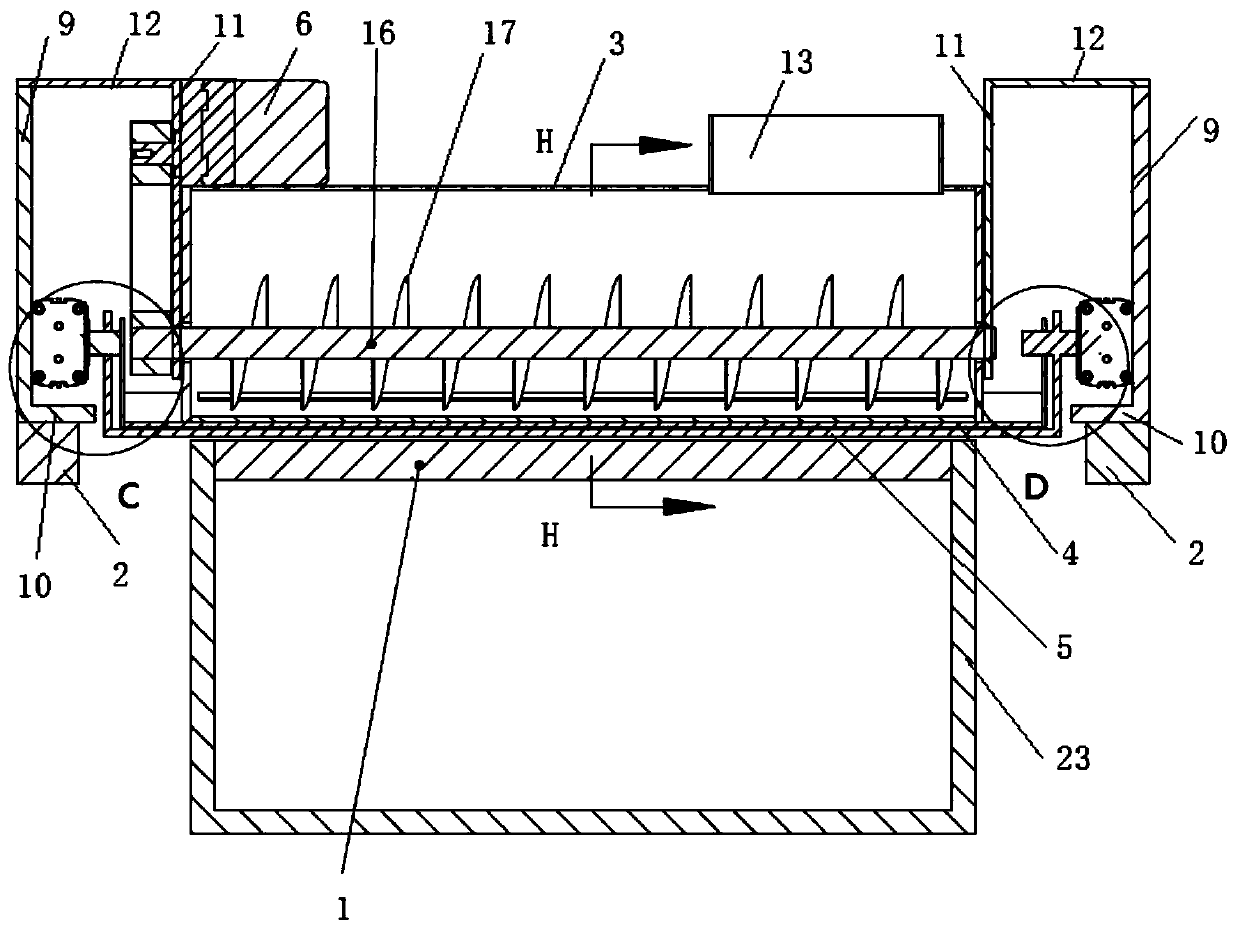

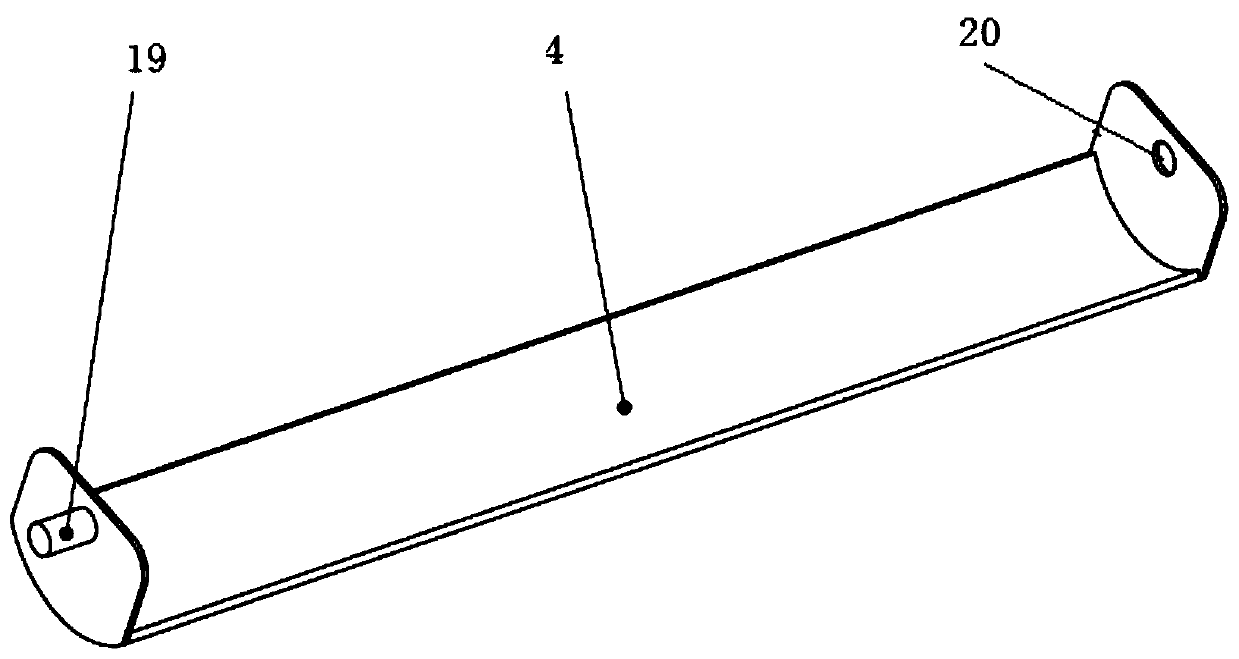

[0035] This embodiment includes all the technical features of Embodiment 1, the difference is that, as Figure 3-Figure 9As shown, the discharge port is arranged on the lower surface of the powder container 3, and the quantity of the discharge port in this embodiment is specifically 2, which are respectively the first discharge port 14 and the second discharge port 15, and the first discharge port The port 14 and the second discharge port 15 are arranged side by side in parallel, and optionally, the feed port 13 is arranged above the powder container 3, the lower surface of the powder container 3 is an arc surface, and the blanking plate 4 is an arc drop. The upper surface of the blanking plate 4 is attached to the lower surface of the powder container 3, and the blanking plate 4 rotates around the axis of the arc surface; the scraper 5 is a straight plate structure; the left and right sides of the blanking plate 4 are respectively A first side plate and a second side plate ar...

Embodiment 3

[0041] This embodiment includes all the technical features of Embodiment 1, the difference is that, as figure 2 As shown, the stirring device includes a central shaft 16 and a helical blade 17. The helical blade 17 is helically wound on the outer wall of the central shaft 16 along the length direction of the central shaft 16, and the two ends of the central shaft 16 run through the left and right sides of the powder container 3 respectively. The side is connected with the left and right sides of the powder container 3 respectively; With such arrangement, the stirring device can disperse and transport powder conveniently and quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com