Safe and heat-insulating car roof cover film and preparation method thereof

A car coat film and safety technology, which is applied in the field of heat-insulating car roof coat film and its preparation, can solve the problems of incompatibility of the car roof surface, accelerated surface material aging, unsatisfactory heat insulation effect, etc., so as to shorten the production time. Time, splash prevention, reasonable effect of film layer design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

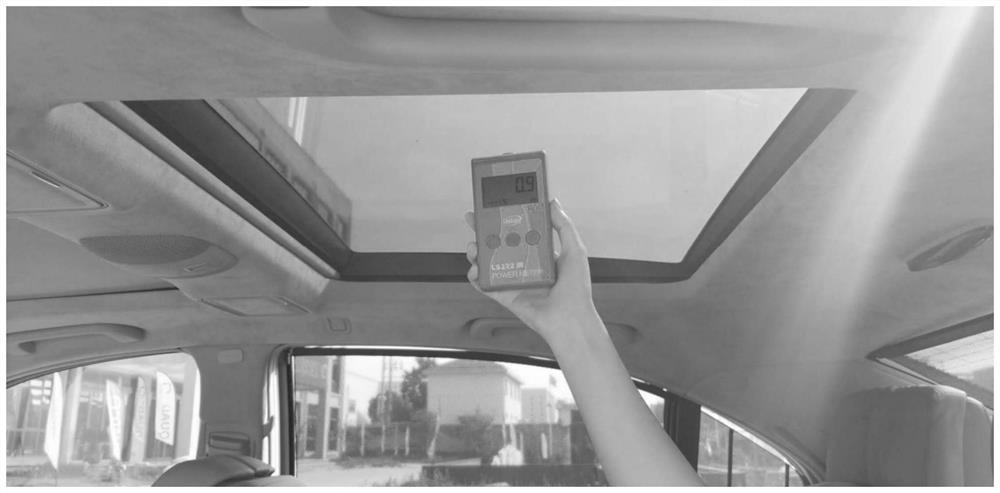

[0033] In order to describe the technical features, purpose and effects of the present invention more clearly, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0034] The preparation steps of a kind of safe heat-insulating roof car coating film of the present invention are described in detail below:

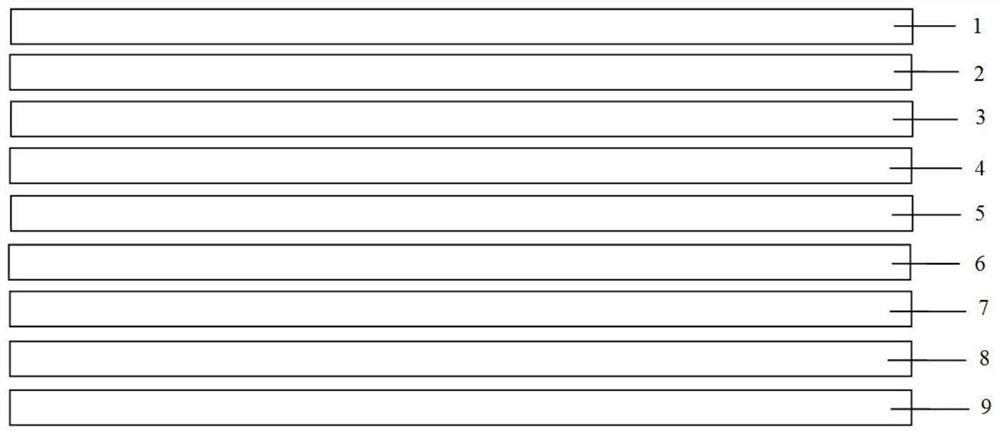

[0035] (1) Firstly, a PET release film layer is provided, and the PET release film is stretched under the condition of a tension of 1250-300N without obvious deformation, as the first release film 1 or the second release film 9;

[0036] (2) Transparent flexible TPU, PVC or PET film is provided as the first base material layer 3, and the visible light band transmittance of the first base material layer 3 is ≥ 45%; The first metal layer 4 is deposited on the substrate layer 3, and the material of the first metal layer 4 can be any combination of one or more metal materials of nickel, chromium, aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com