Pretreatment method of new energy biomass material

A biomass raw material and biomass technology, applied in the direction of biofuel, waste fuel, material molding presses, etc., can solve the problems of increasing the difficulty of transportation, low utilization rate of biomass combustion heat, and different compactness, etc. Achieve convenient transportation and improve heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

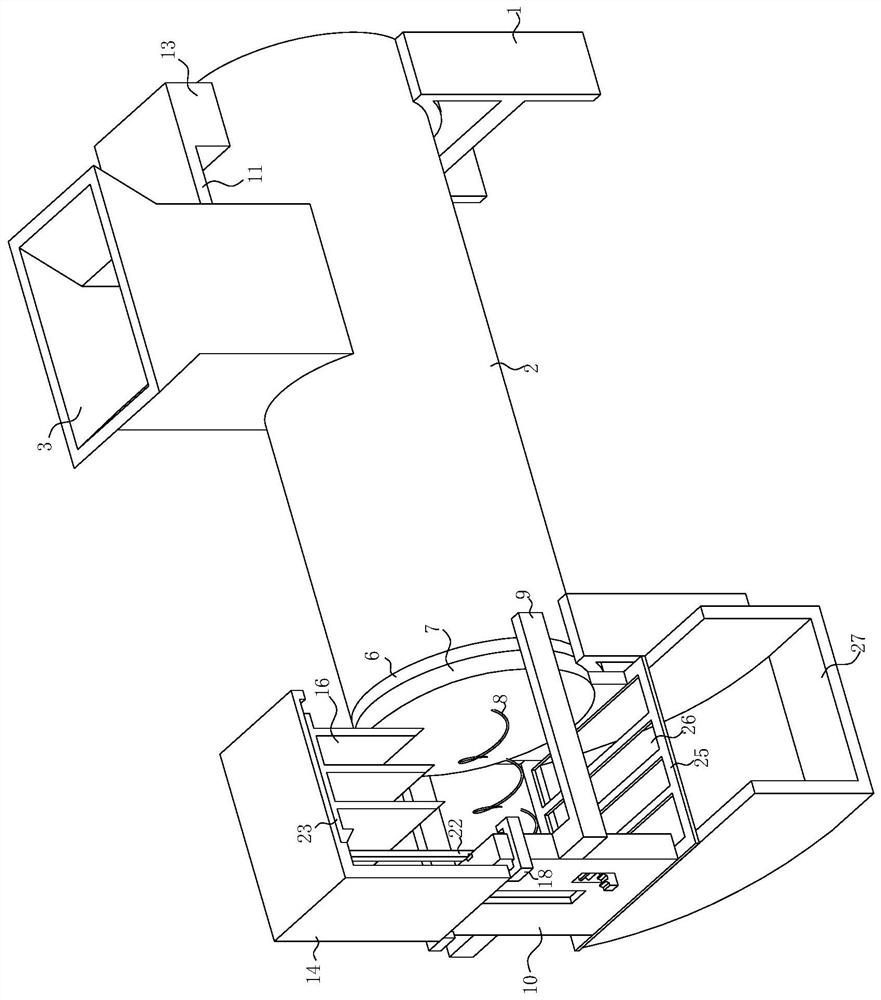

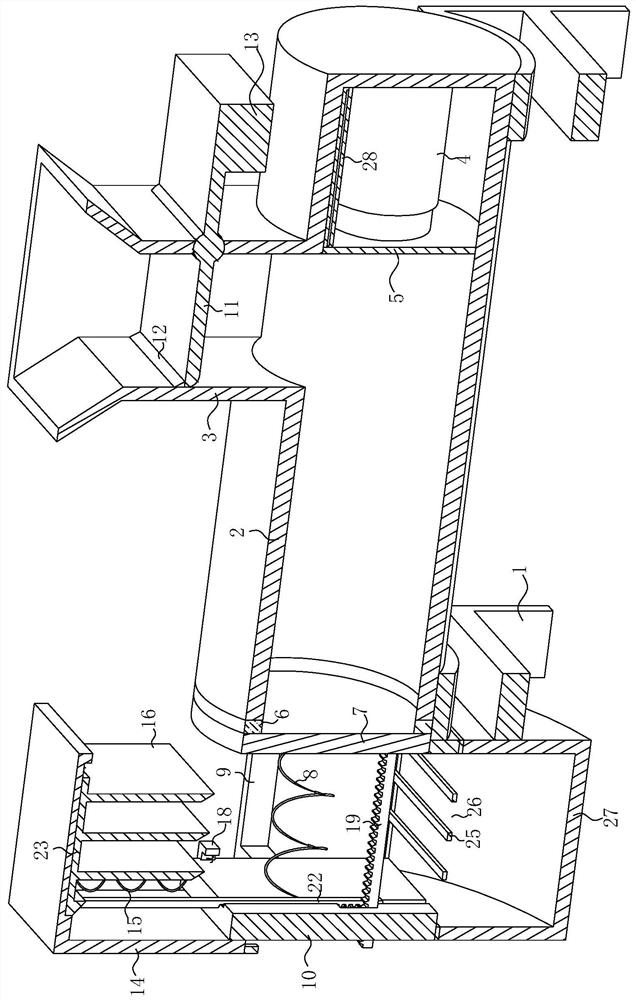

[0033] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained in the preparation of creative labor.

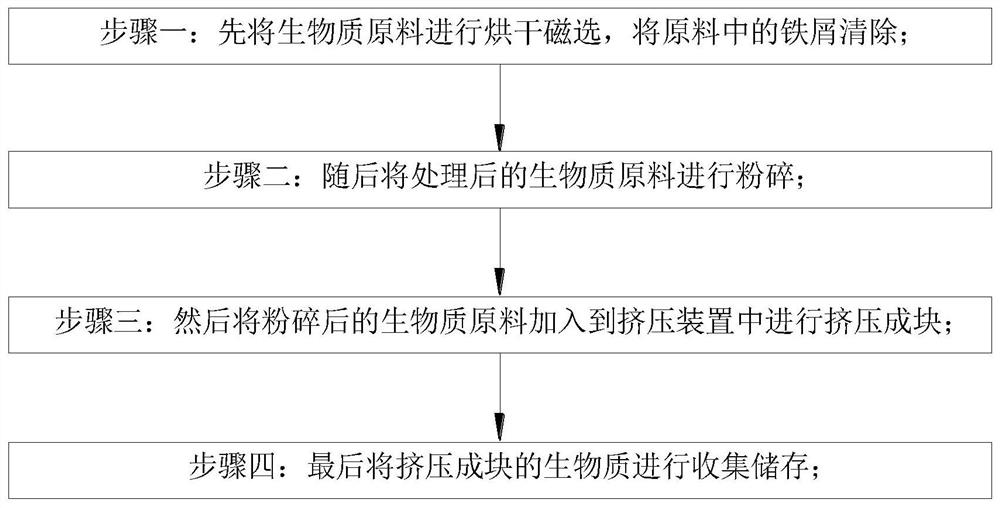

[0034] See Figure 1-8 The present invention provides a technical solution: a new method for pretreatment of biomass energy materials, or the specific method steps of the process are as follows:

[0035] Step a: first magnetic drying the biomass feedstock, the feedstock remove iron;

[0036] Step two: then treated pulverized biomass feedstock;

[0037] Step Three: then pulverized biomass feedstock introduced into the extrusion apparatus for extruding into chunks;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com