Street brick laying machine

A technology for laying bricks and streets, applied in the direction of roads, roads, road repair, etc., can solve the problems of insufficient smooth paving, large labor, low efficiency, etc., and achieve the effect of reducing manual brick holding and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

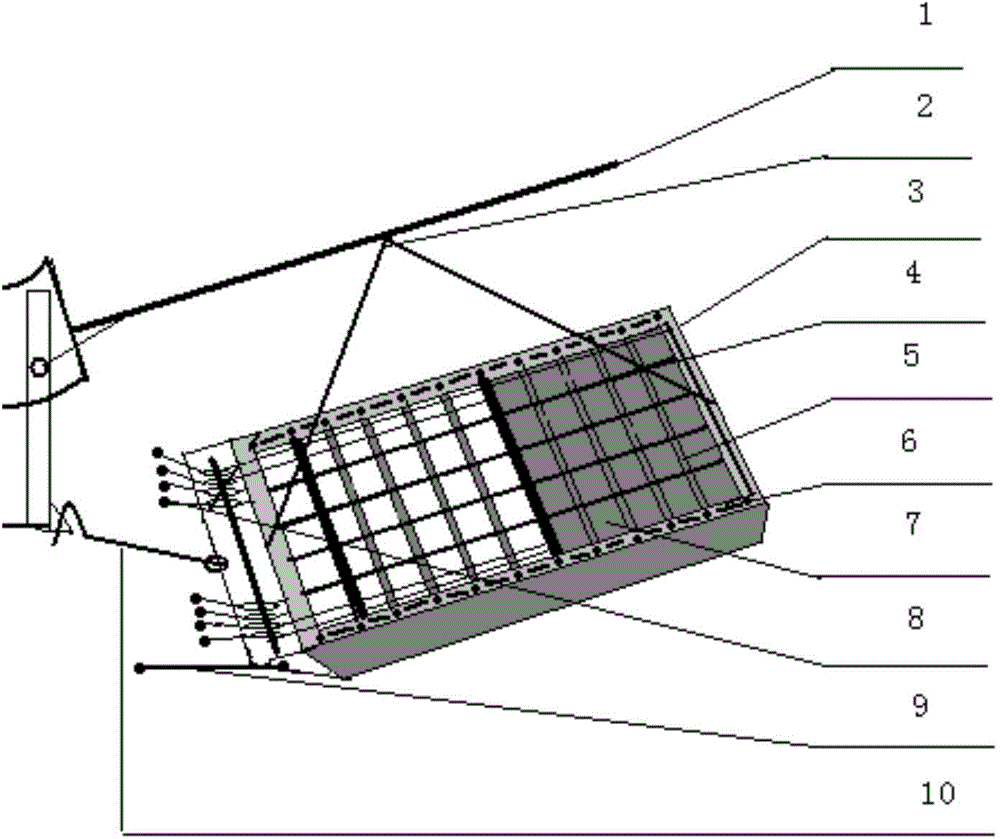

[0014] When using the above-mentioned street paving machinery, first use a power shifting device (forklift or four-wheel lifting device)

[0015] Move the brick-laying machinery to the top of the brick stack, then descend to arrange the bricks (the brick stack is in a cube), then pull the tightening handle to tighten the brick grid, the power shifts, and then descend again to perform the second and third brick laying. Brick row, the fourth row of bricks (the maximum brick row capacity of this machine is 4 square meters). After the brick arrangement is completed, the power is shifted to the laying area, and then according to the orientation of the laying area, adjust the position of the laying frame, align it with the laying point and lower it, wait for the laying frame to land on the bed surface smoothly, release the expansion handle, the brick grid is loose, and then lift the laying frame again Brick frame, that is to complete a brick laying activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com