Quick formwork supporting device

A supporting device and formwork technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., which can solve the difficulty of supporting and reinforcing concrete pouring formwork, increased construction costs, and can not be reused. Use and other issues to achieve the effect of ingenious structural design, strong turnover, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

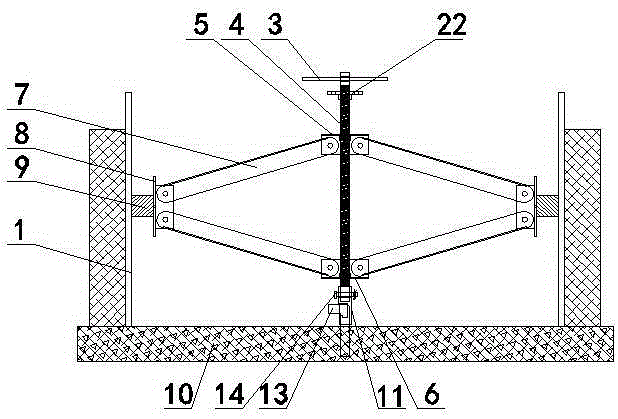

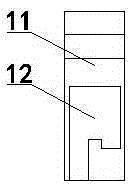

[0026] Embodiment 1: as figure 1 As shown, a template quick support device includes vertical and symmetrically arranged templates 1, and a plurality of support devices for supporting the template 1 are longitudinally arranged between the templates 1, and the adjacent support devices pass through The connecting rods 2 are connected, and the two ends of the support device are respectively connected with the templates 1 on both sides.

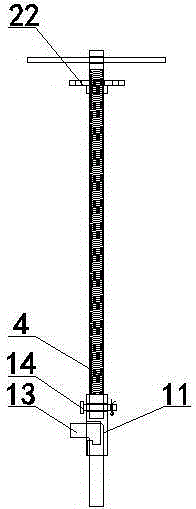

[0027] Wherein, the supporting device includes a vertically arranged screw 4 with a detachable handle 3, on which at least one diamond-shaped connecting rod mechanism is arranged, and the two ends of the diamond-shaped connecting rod mechanism are connected with the templates on both sides respectively. 1 connection.

[0028] Such as Figure 6 As shown, at least two rhombic connecting mechanisms are provided on the screw 4 , and one end of the connecting arm 7 of the adjacent rhomboid connecting mechanisms is connected through a movable connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com