Hydraulically Driven Tilting Garage Adopting Chain Synchronization Mechanism

A synchronous mechanism and tilt-up technology, which is applied in the field of hydraulically driven tilt-up garages, can solve the problems of vehicle-carrying plate bending, poor safety, and inconvenient installation, and achieve increased parking space, convenient installation and maintenance, and safe and reliable use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

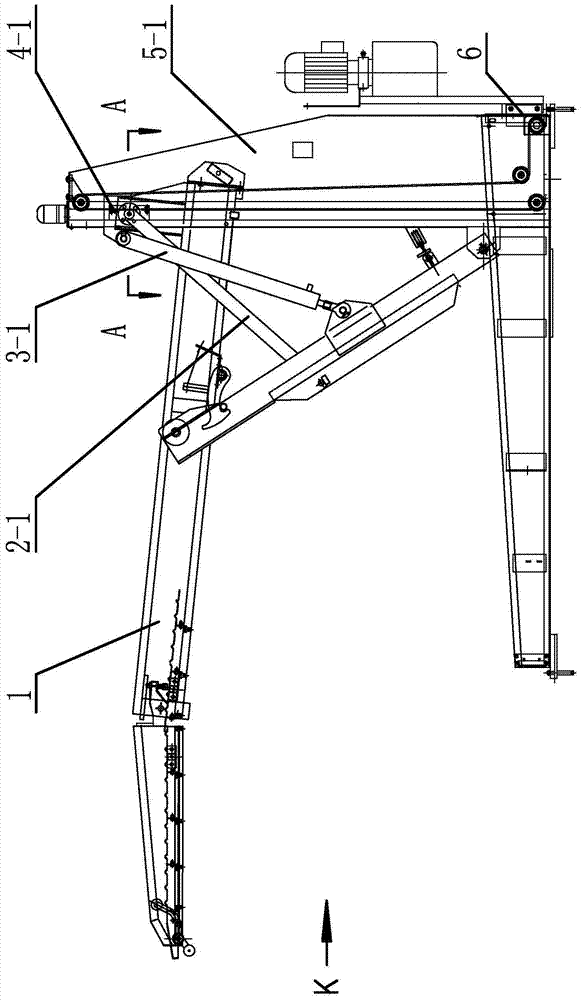

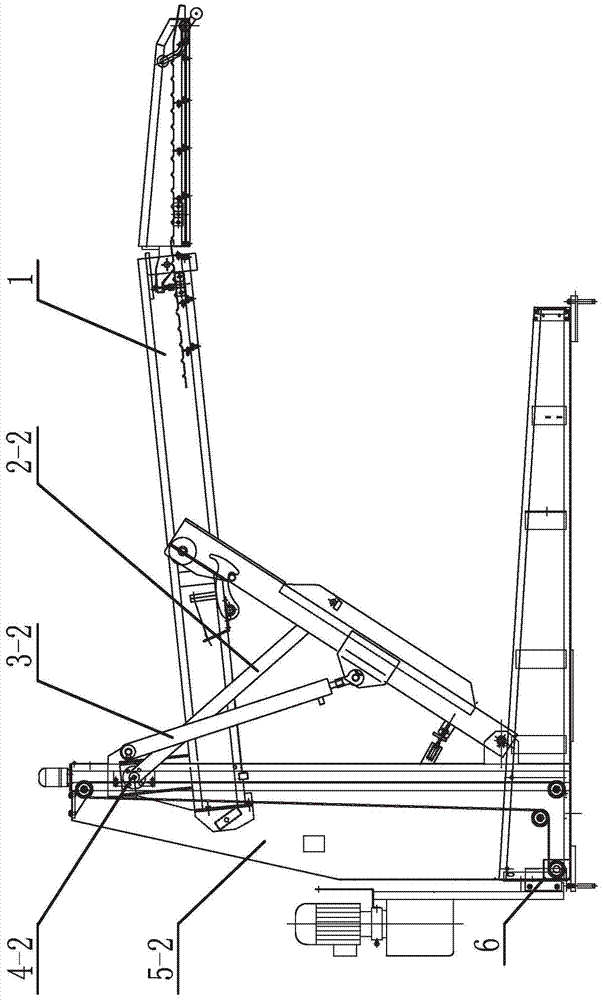

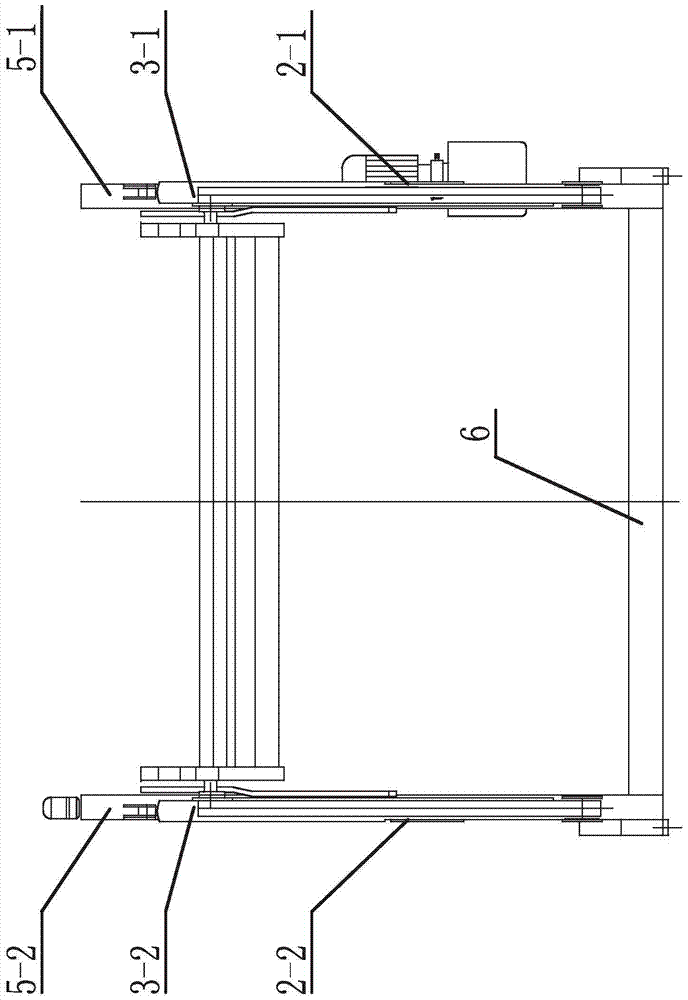

[0030] The detailed technical contents and embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as Figure 1-Figure 7 As shown, the hydraulically driven tilting garage adopting a chain synchronous mechanism includes a chain synchronous mechanism that keeps the two driving cylinders 3-1 and 3-2 arranged on both sides of the vehicle-carrying plate 1 in a synchronous manner. Oil cylinders 3-1, 3-2 are lifted synchronously, and the lifting of the vehicle-carrying plate 1 is realized by two driving oil cylinders 3-1, 3-2; the chain synchronous mechanism includes symmetrically arranged left and right support columns 5-1, 5-2, each of which has a There is a set of coaxial sprocket mechanism in the rear connection bracket 6 that covers the chain mechanism and the left and right support columns 5-1, 5-2; Institutions are connected.

[0032] The left and right chain mechanisms are respectively arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com