Pulling and running device of solid anti-wax device for rodless lifting well and pulling and running technology thereof

A solid, wax-proof technology, used in wellbore/well components, earth-moving drilling, etc., can solve the problems of prolonging the wax-proof period, reducing the service life of the whole unit, frequent wax deposition in oil wells, etc. cycle, prolong the anti-wax cycle, save the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

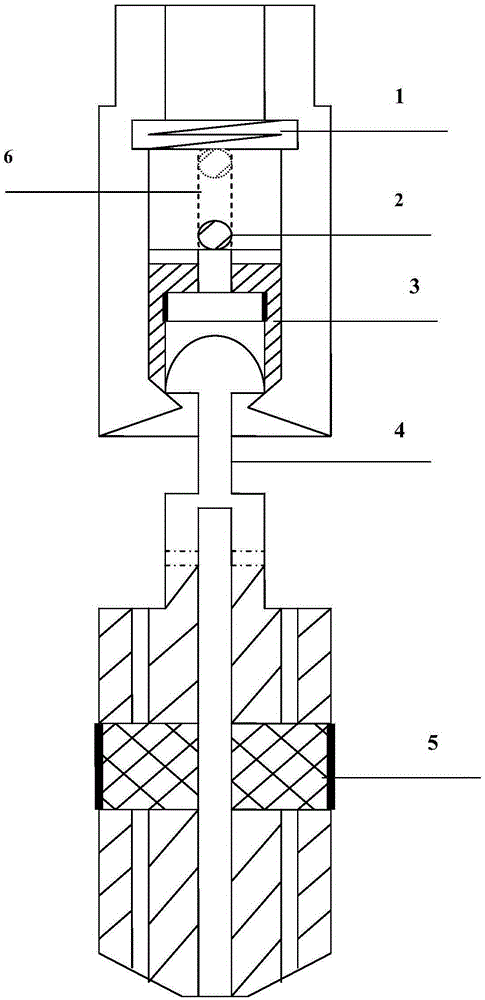

[0015] detailed description: Below in conjunction with accompanying drawing, the present invention is described further: this technique is realized by following device: it is made up of spring 1, limit pin 2, card 3, butt joint 4, solid wax preventer 5, guide shaft 6; Spring 1, limit pin 2, and card 3 form a card release device, spring 1 is connected with guide shaft 6, card 3 is connected with guide shaft 6 by welding, card 3 is connected with butt joint 4, and butt joint 4 is connected with solid wax preventer 5 threaded connection, the limit pin 2 can move in the guide shaft 6; this process is realized through the following steps:

[0016] a. First, dock the card 3 in the card remover with the butt joint 4 on the ground, and the device is lowered to the predetermined shaft depth with the wire rope winch;

[0017] b. Secondly, when the solid wax preventer 5 reaches the predetermined depth, the device continues to move downward under the action of inertia, and the limit pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com