Connection structure for air flue pipe on airplane

A technology for connecting structures and aircraft, which is applied in the aviation field, can solve the problems of large influence of aircraft weight, poor shock absorption and compression resistance, unfavorable aircraft weight reduction, etc., and achieve the effects of long service life, good sealing and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

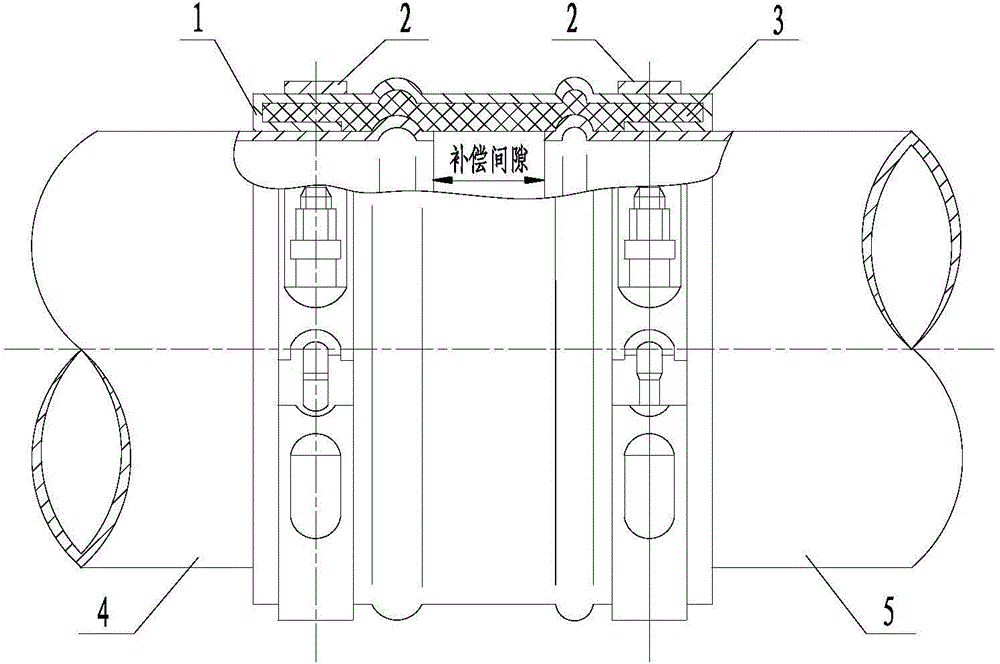

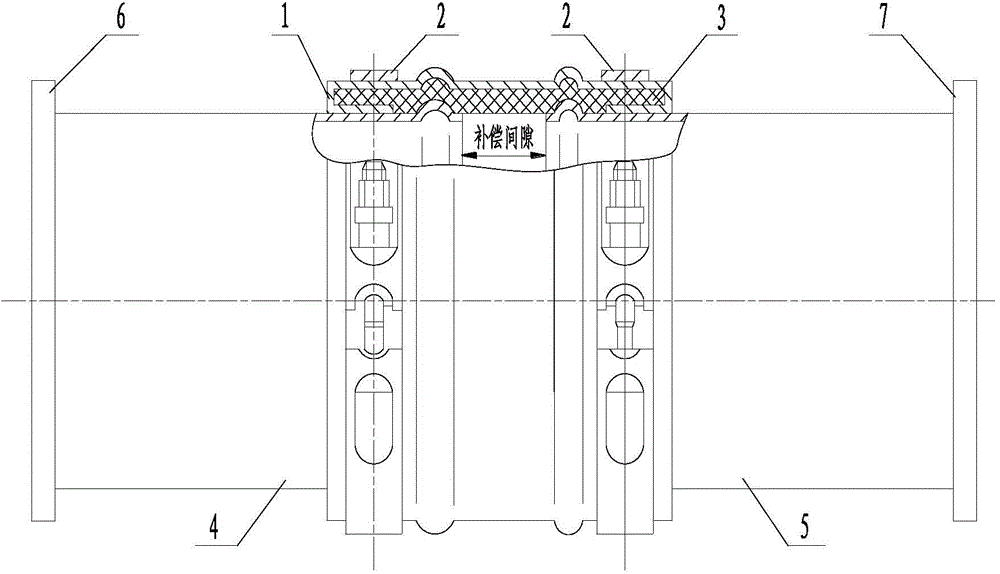

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] One end of the left metal conduit 4 is welded with the left flange 6, and one end of the right metal conduit 5 is welded with the right flange 7. The left flange 6 and the right flange 7 are connected together with an accessory or an aircraft fixed structure by bolts. There is a certain compensation gap when the other ends of the left metal conduit 4 and the right metal conduit 5 are connected, and the flexible heat-resistant rubber hose 3 with a circular cross section presses the rolling bosses at both ends of the left metal conduit 4 and the right metal conduit 5 tightly together , the grounding gasket 1 is lapped on the left metal conduit 4 and the right metal conduit 5, the section of the ring clamp 2 is almost circular, and the two ring clamps 2 are fixed on the left metal conduit 4 and the right metal conduit 5. On the outside of the wave boss, fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com