A disc-type workpiece detection station adjustment tool for coordinate measuring machines

A coordinate measuring machine, workpiece detection technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as difficulty in turning over in space, and achieve the effects of high efficiency, short assembly cycle, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

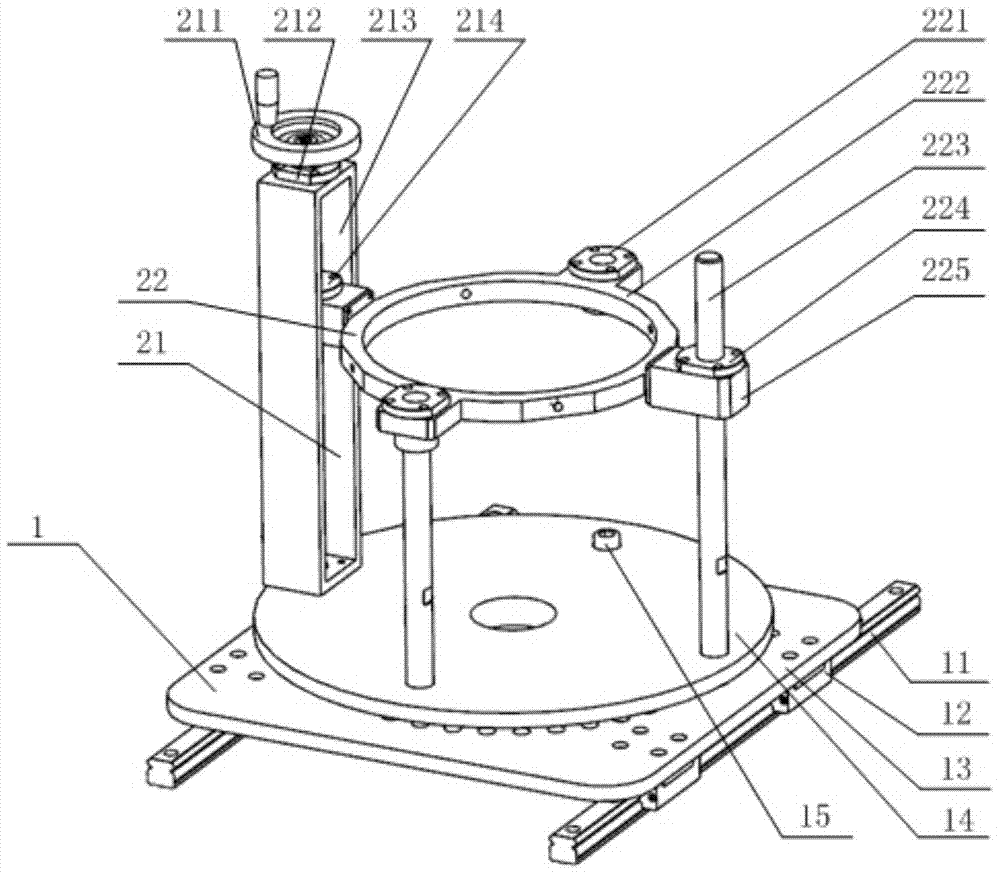

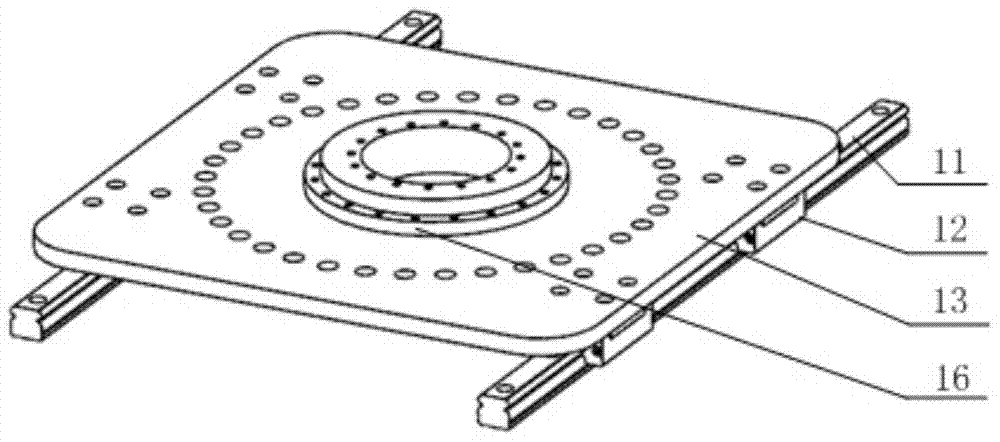

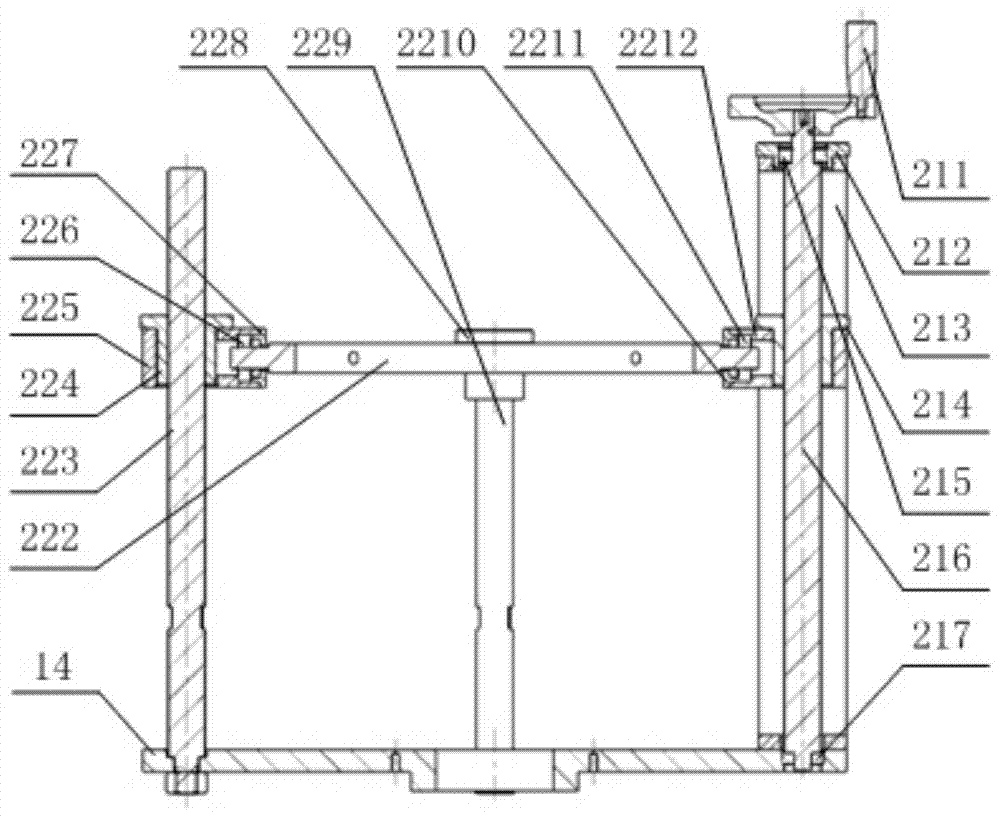

[0048] see figure 1 , the disc workpiece detection station adjustment tool for coordinate measuring machines in this embodiment is composed of three parts: a base 1, a lifting device 21 and a turning device 22, wherein the base 1 is a horizontal rotating base, see figure 1 , figure 2 , the base is composed of two linear guide rails 11 arranged in parallel, guide rail sliders 12, bottom plate 13, rotating plate 14, fixed pins 15 and bearings with flanges 16, the two linear guide rails 11 arranged in parallel and installed on them The guide rail slider 12 is the bottom part of the entire tooling. The standard interface hole on the linear guide rail 11 can be used to install the entire tooling on the coordinate measuring machine table. The bottom plate 13 and the guide rail slider 12 are fixedly connected by screws, with flange bearings 16 Respectively with base plate 13 and rotating plate 14 (not in figure 2 centered, see figure 1 ) are fixedly connected by screws, a centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com