Patents

Literature

42results about How to "Short assembly cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for precisely assembling space remote sensing camera body structure

InactiveCN101571389AOvercome the shortcomings of low assembly accuracy and high stressLow costPicture taking arrangementsEngineeringRemote sensing

The invention provides a method for precisely assembling a space remote sensing camera body structure, belonging to the technical field of assembly connection of body equipment. The method is to use a glue film as the close loop size of body assembly, lead assembly precision and assembly stress to depend on the deflection of the glue film, cancel the pad which may generate larger error, change the assembly mode of a transition component from glue connection first and screwed connection second of mechanical connection method into screwed connection first and glue connection second, use the metal pad to be wound on the transition component to be closely matched with an inner hole of a strut, and better achieve the aims of small assembly stress, high assembly precision and steady and firm structure through a microstress glue connection method. The glue connection method reduces the stress of the body structure on sensitive orientation, namely on axial of the strut, and optimizes the stress status of the body. Meanwhile, the method has simple and convenient operation, short assembly period and low cost, and overcomes the defects of long period and high cost of the prior assembly method by finishing the pad.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

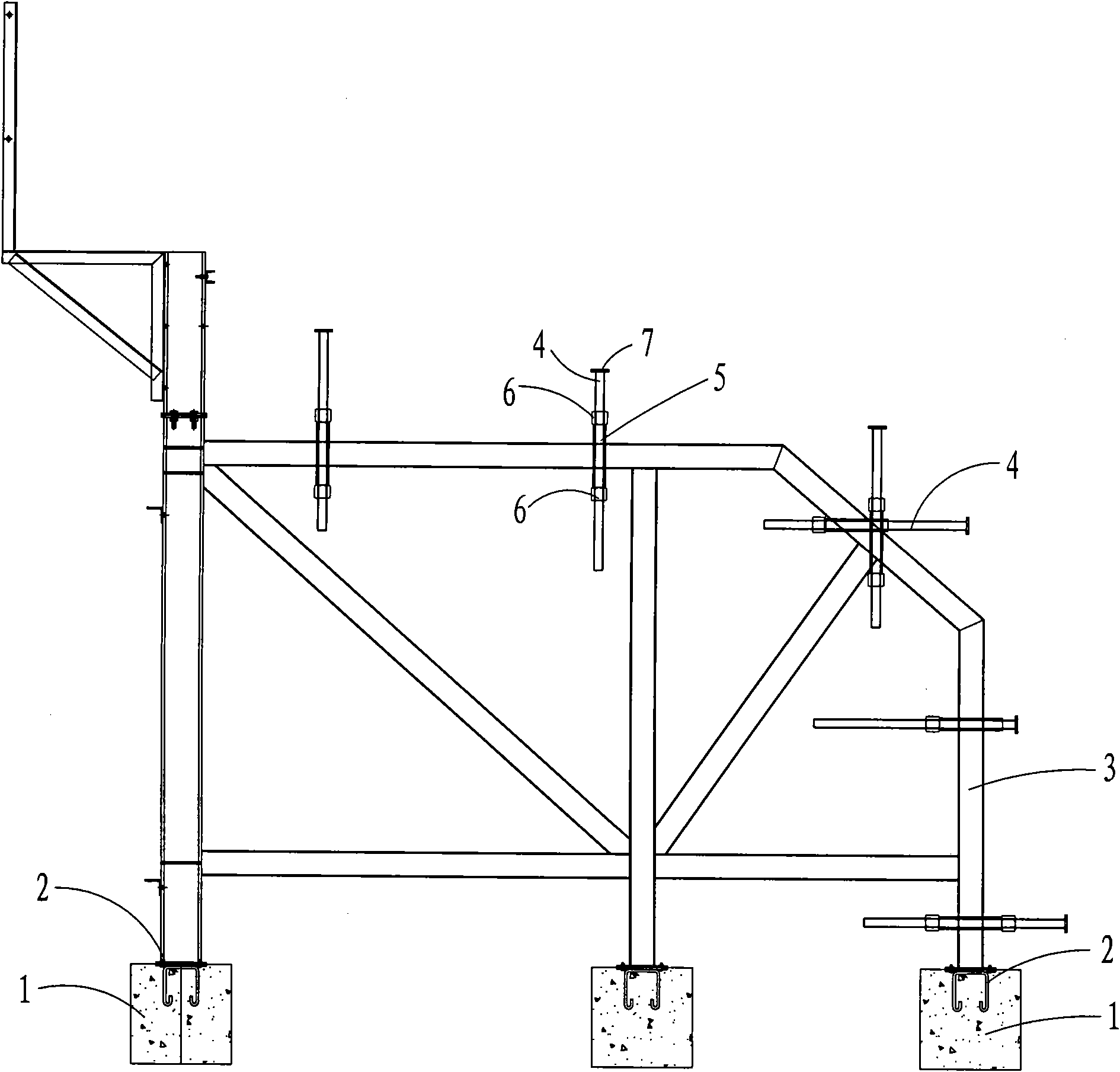

Assembled adjustable steel bar binding clamping fixture support

ActiveCN101890757AMeet the requirements of steel bindingEasy to adjustCeramic shaping apparatusSheet steelSteel bar

The invention discloses an assembled adjustable steel bar binding clamping fixture support which is characterized by taking a steel plate assembly pre-buried in a pier column at the bottom part as a mounting foundation; a support frame is fixedly mounted on the steel plate assembly through a bolt according to the shape of beam body steel bars; support rods are arranged on the support frame at intervals, the supporting height of the support rods on the support frame can be adjusted, and an end plate used for fixing and position-limiting of angle iron is arranged at the support end of each support rod. The assembled adjustable steel bar binding clamping fixture support can greatly improve the mounting speed of a steel bare binding clamping fixture, adjust the positioning precision of the binding clamping fixture with high efficiency, quickly realize the university among a plurality of beam types, be utilized repeatedly and realize energy conservation and emission reduction.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

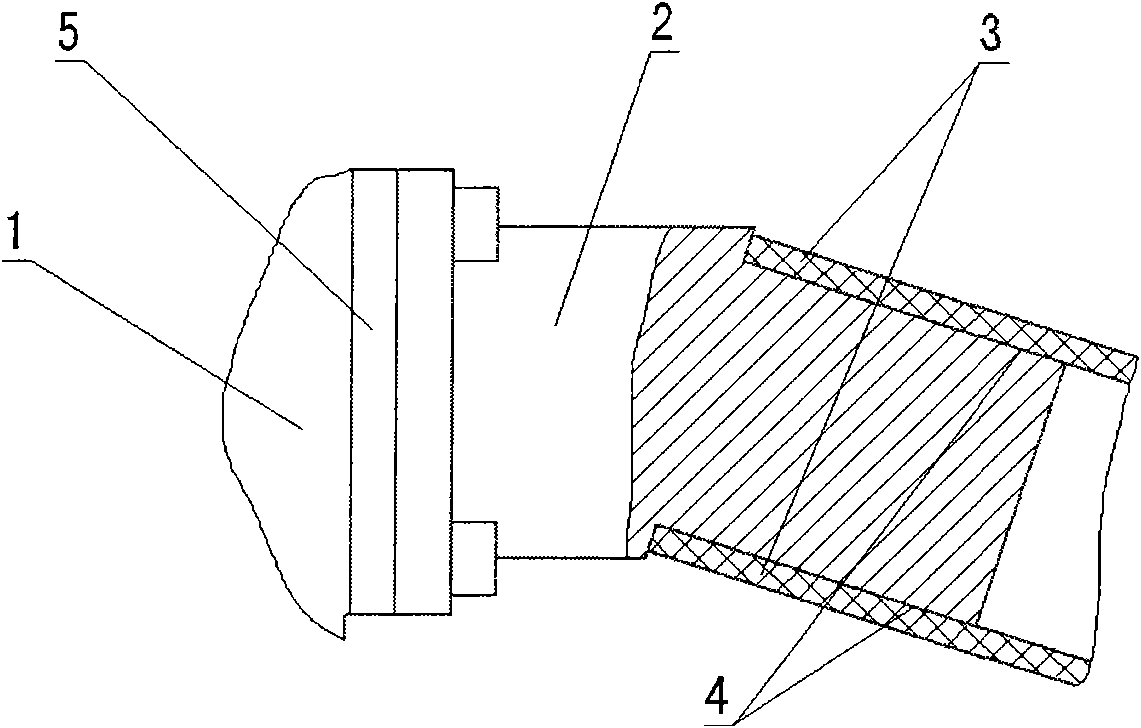

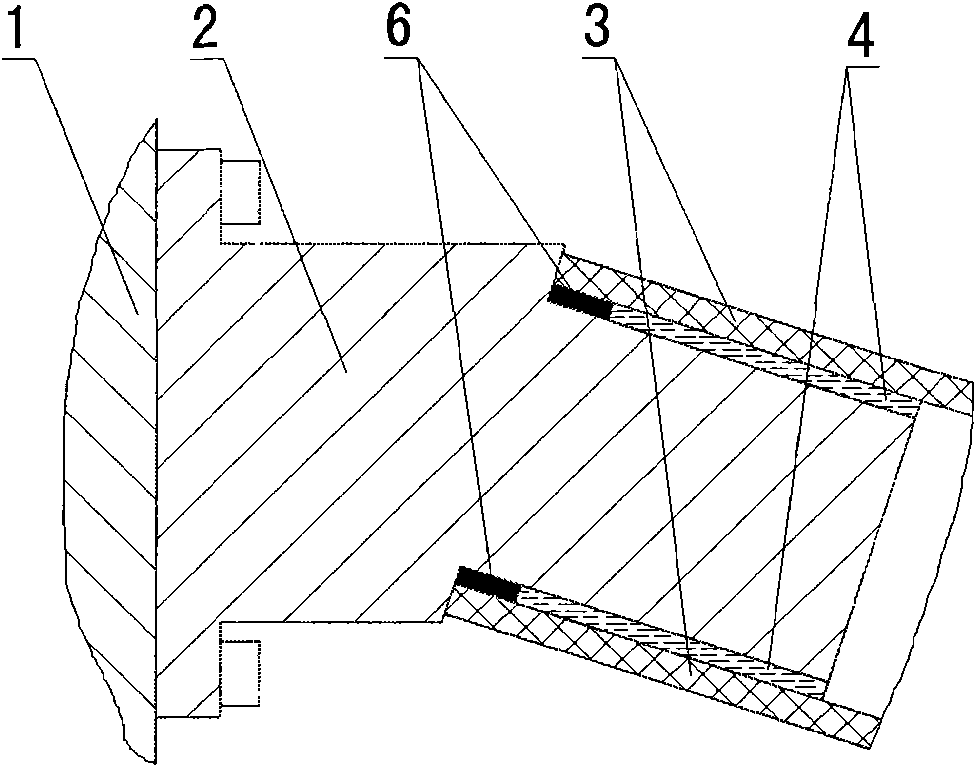

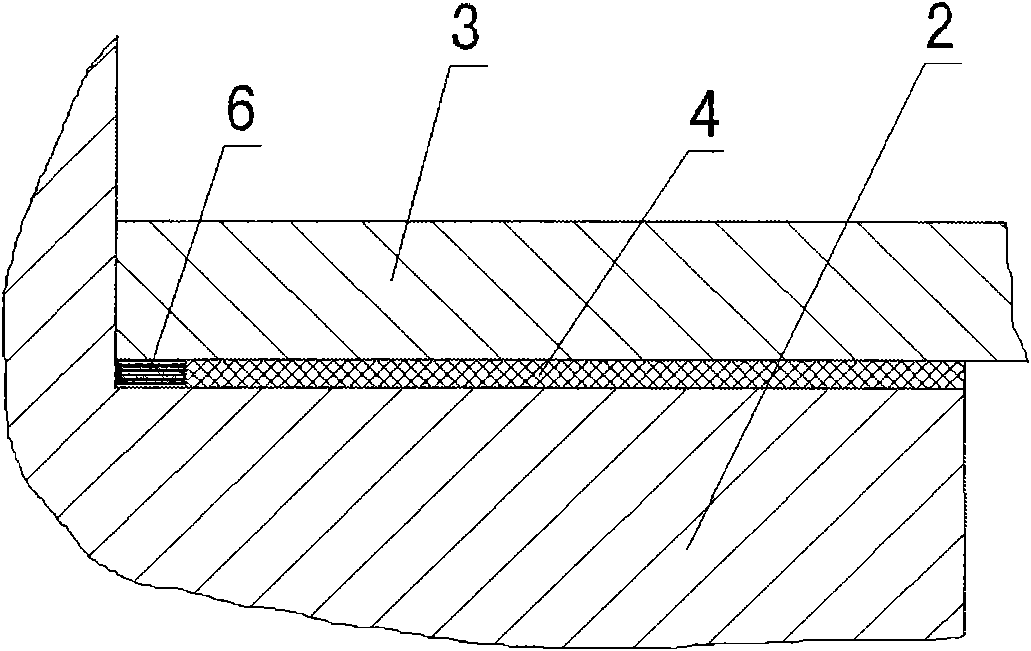

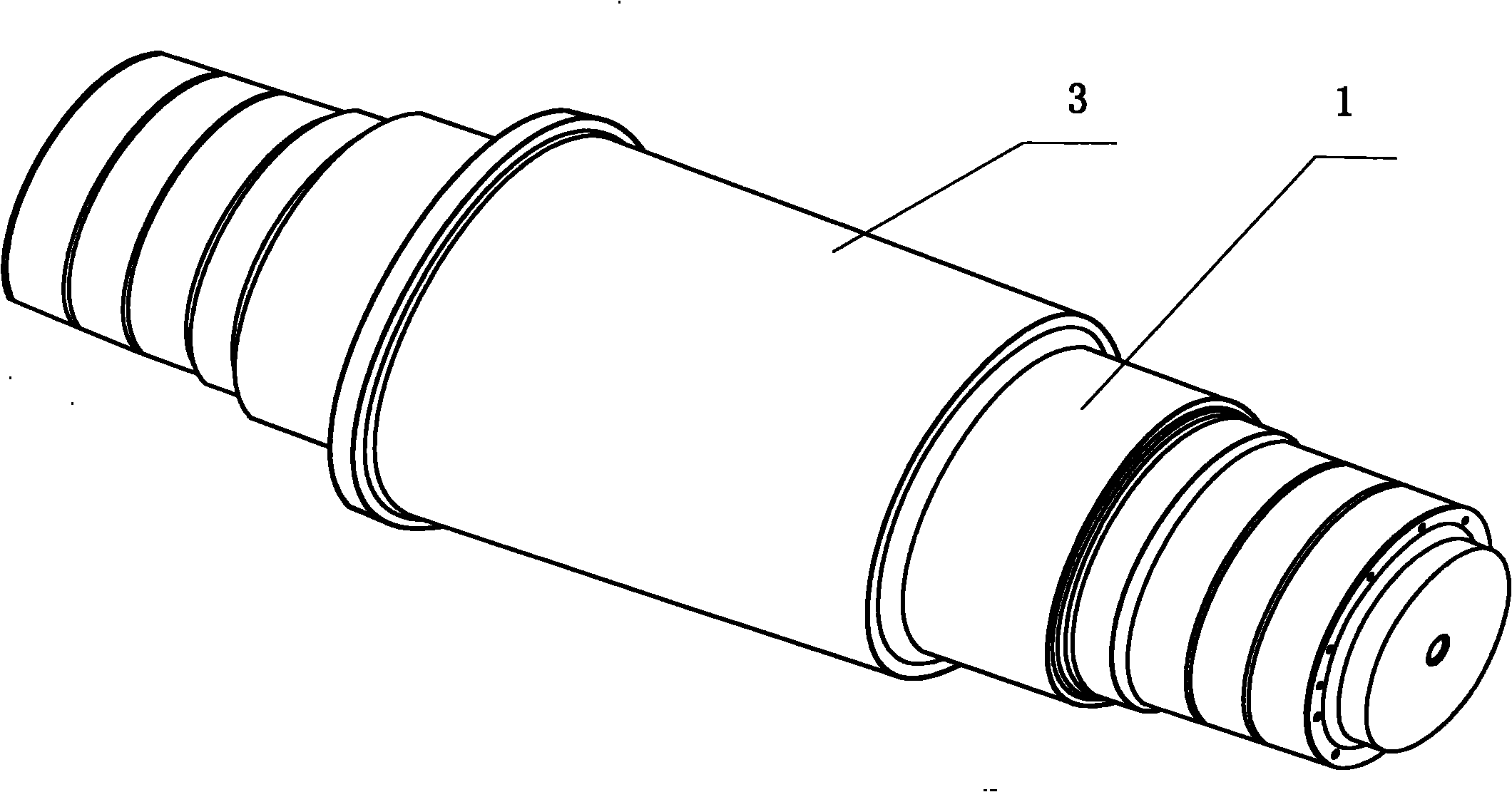

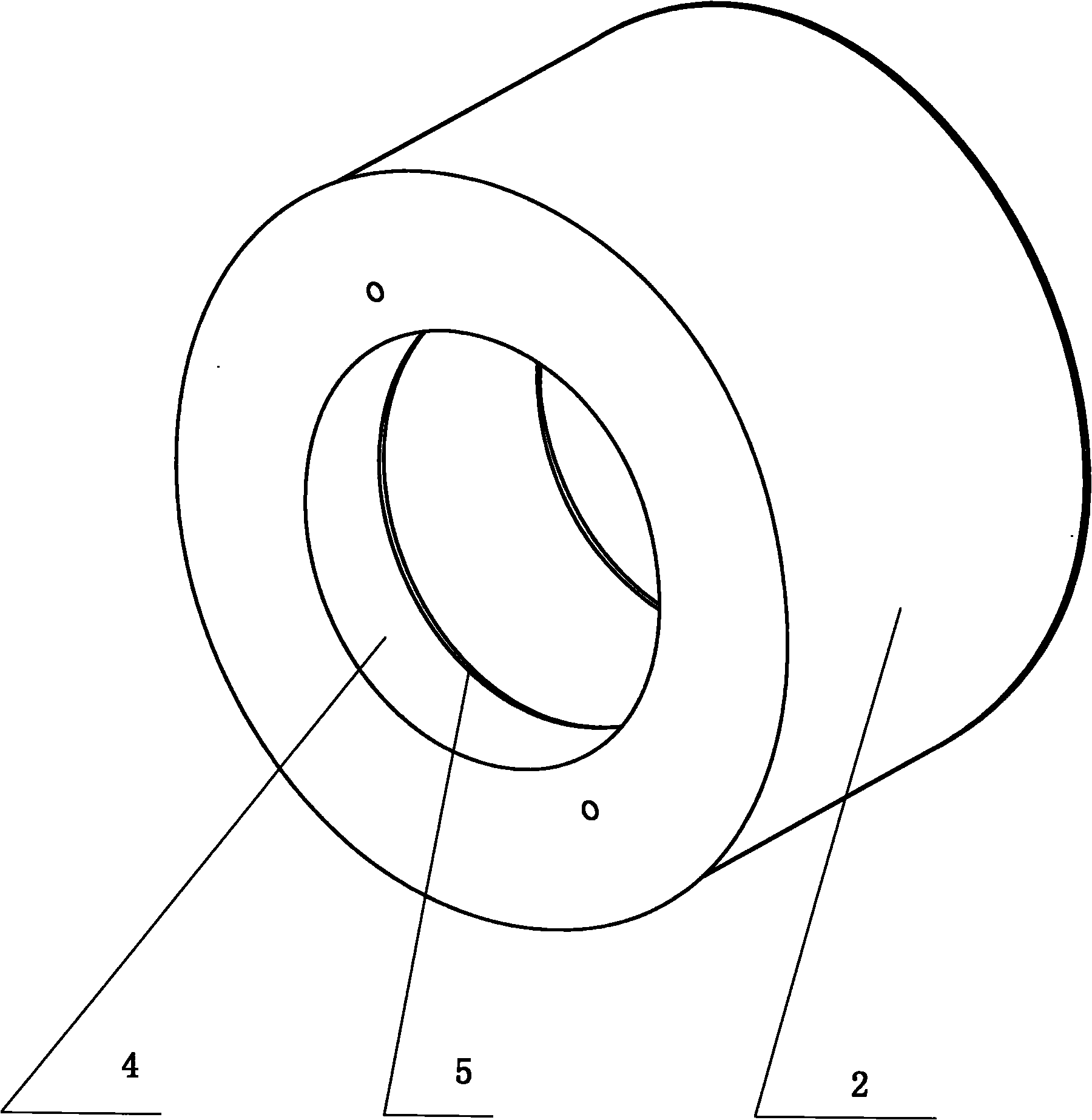

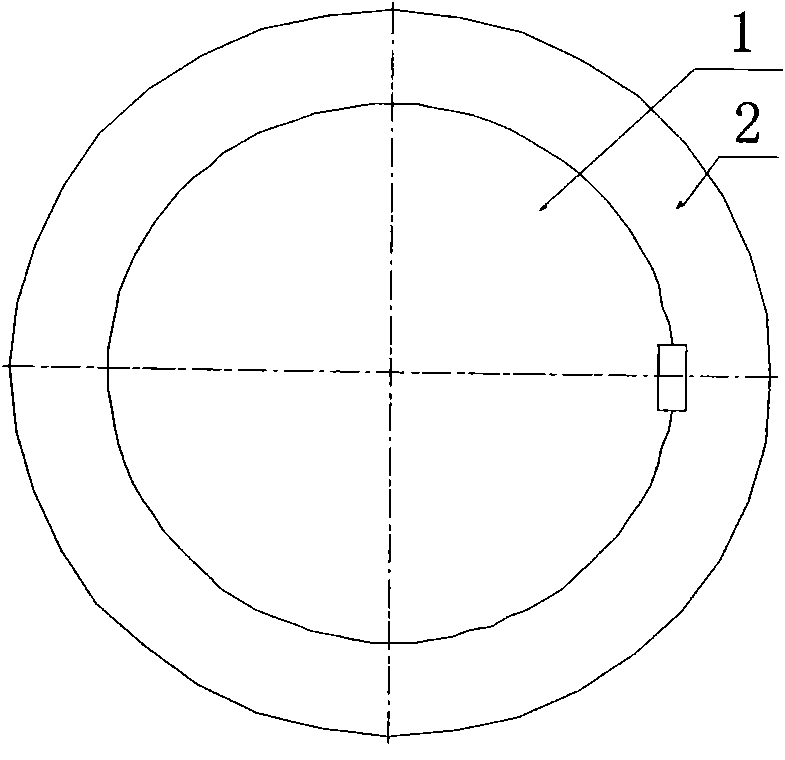

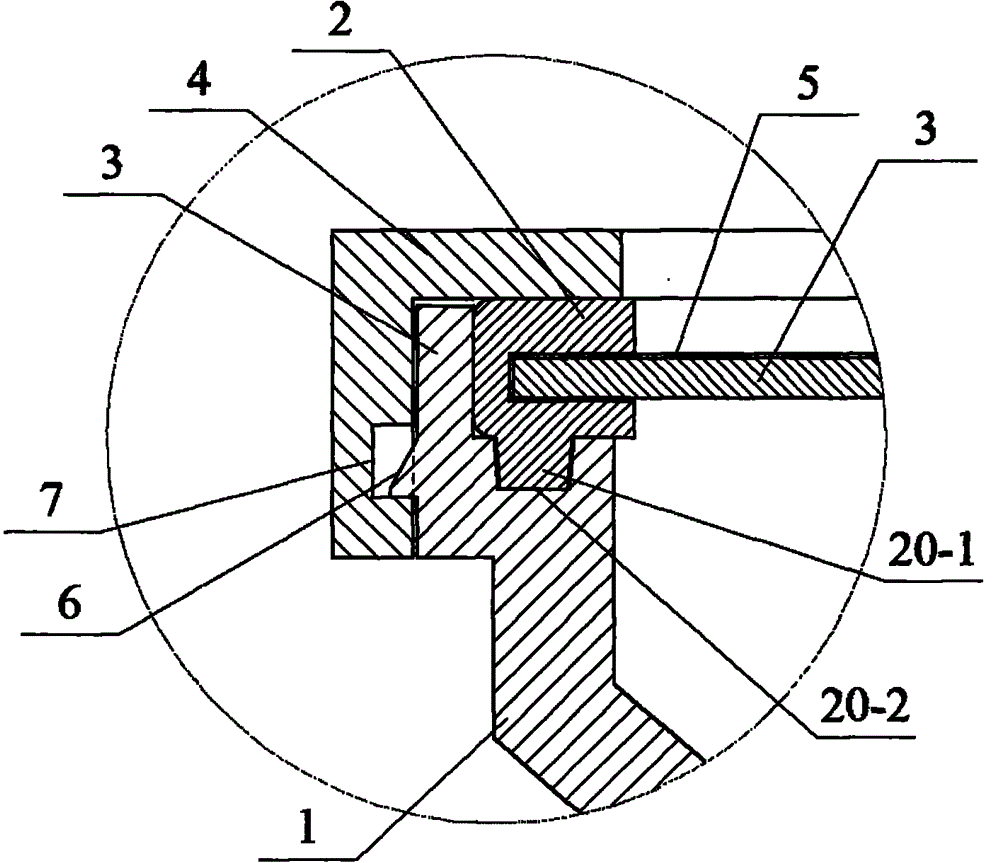

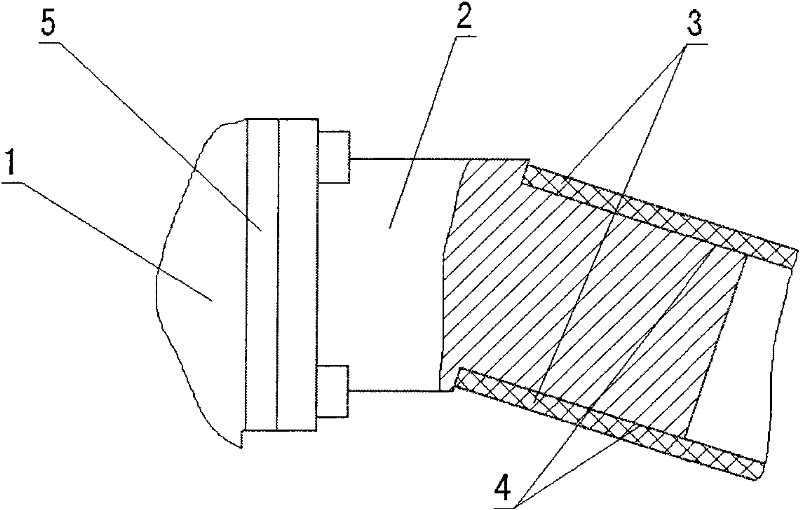

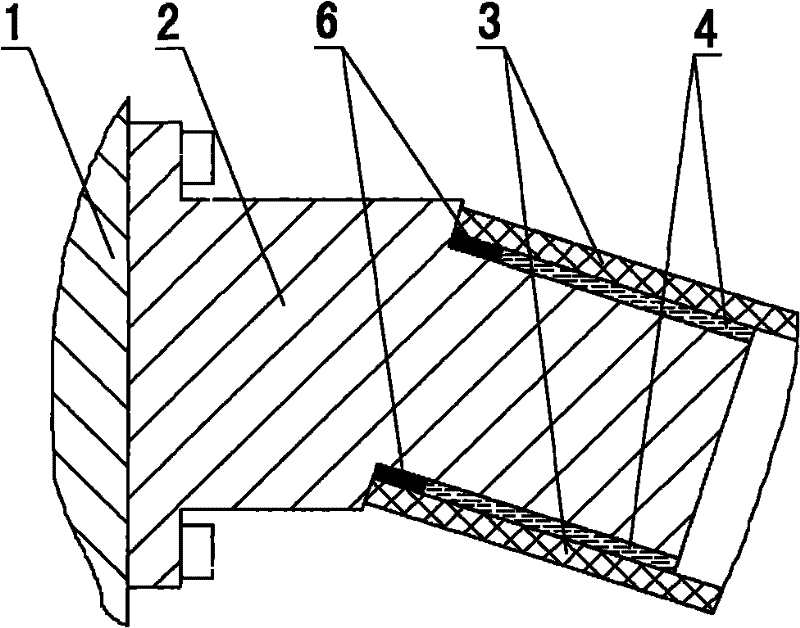

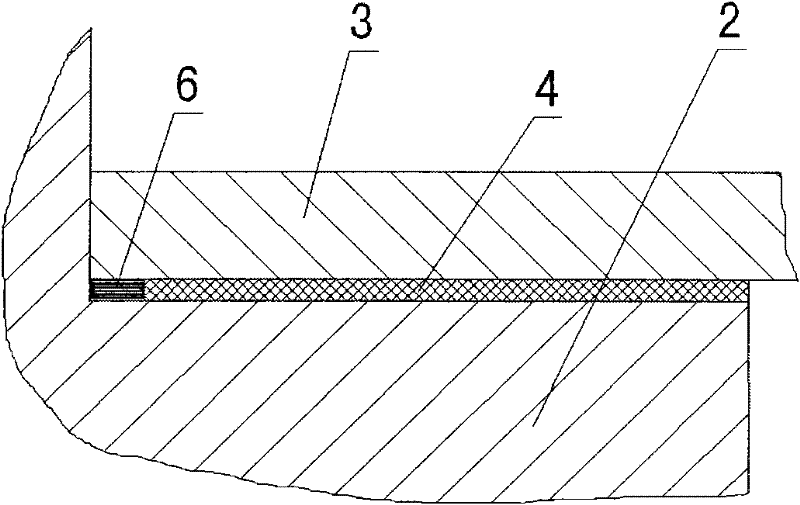

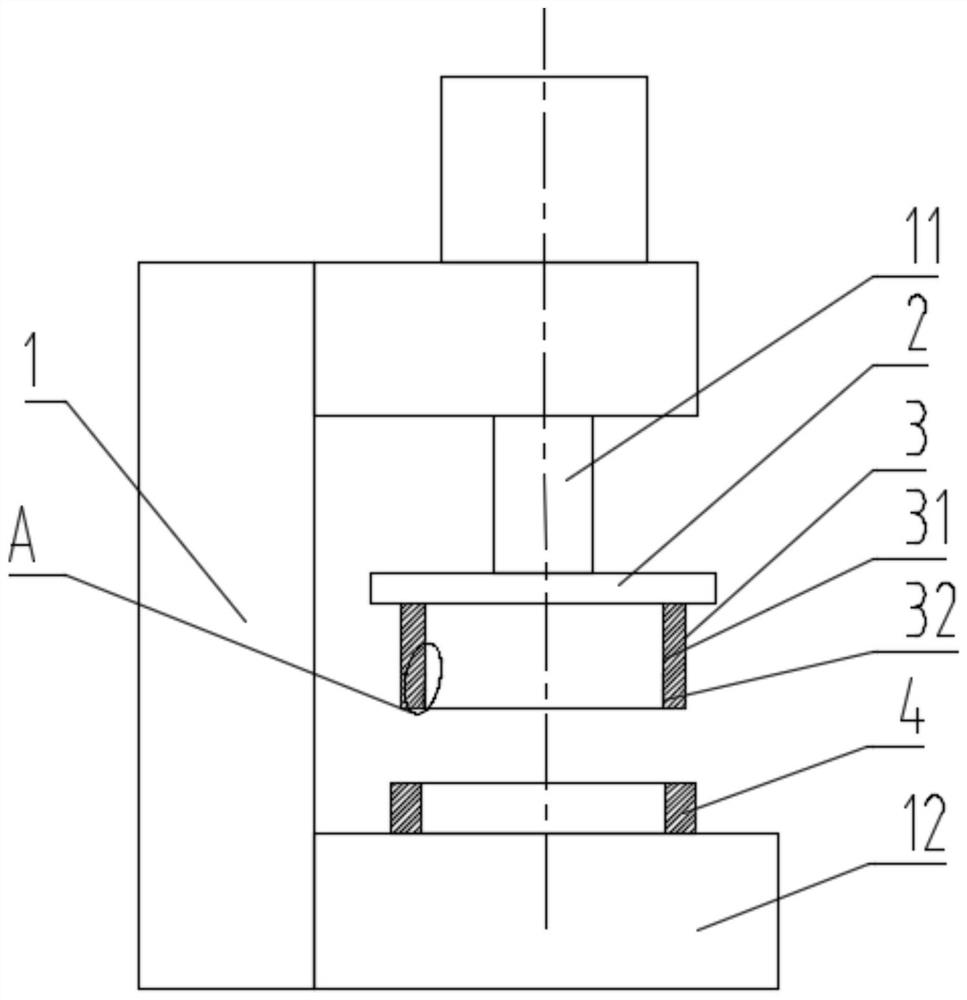

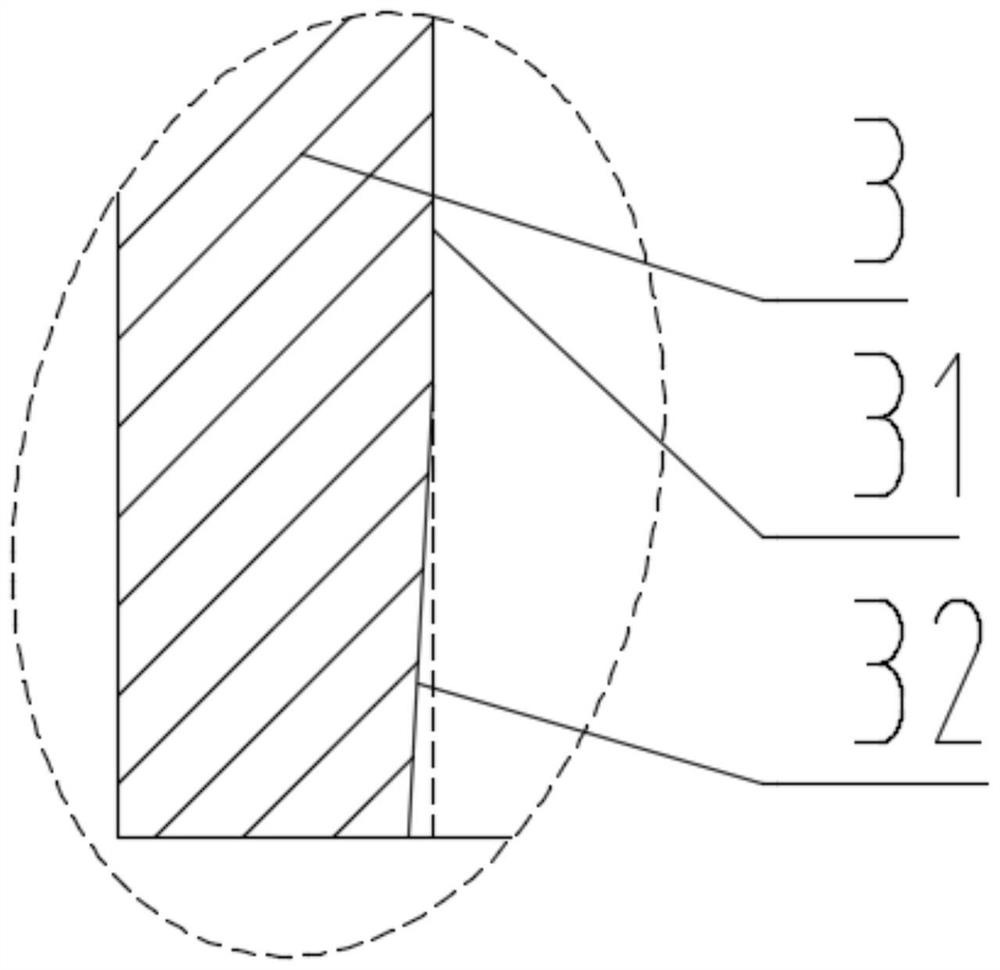

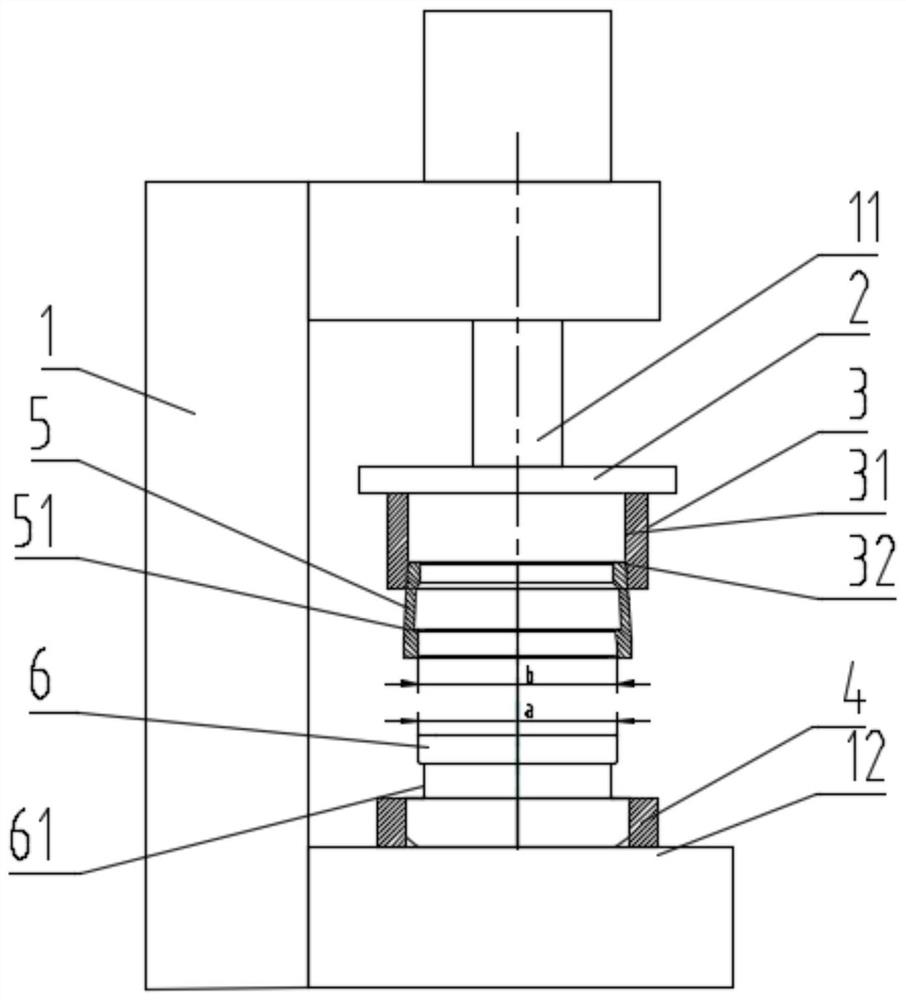

Split-type squeeze roller assembly structure and assembly method

InactiveCN101786031AExtended service lifeAvoid stress concentrationGrain treatmentsMetal working apparatusStress concentrationInterference fit

The invention discloses a split-type squeeze roller assembly structure and an assembly method. The squeeze roller assembly structure comprises a roll shaft (1) and a roll sleeve (2), wherein matching positions of the outer conical surface (3) of the roll shaft and the inner conical hole (4) of the roll sleeve are in a conical surface shape, the roll shaft (1) and the roll sleeve (2) are in shrink fit connection, and the matching position of the inner conical hole (4) of the roll sleeve is a double-oil groove (5) conical surface. The assembly method of the squeeze roller comprises the following steps: processing the matching surface of the roll shaft and the roll sleeve into the outer conical surface (3), processing the matching surface of the roll sleeve and the roll shaft into the inner conical hole, and processing the matching surface of the inner conical hole (4) of the roll sleeve or the outer conical surface of the roll shaft into a multi-oil groove (5) conical surface, wherein the side of the roll shaft or the roll sleeve is provided with an oil filler point. The invention can shorten assembly period of squeeze roller sleeves, greatly reduce stress concentration caused by shrink fit connection of roll shafts and roll sleeves, prolong life service of squeeze rollers, and improve product performance.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

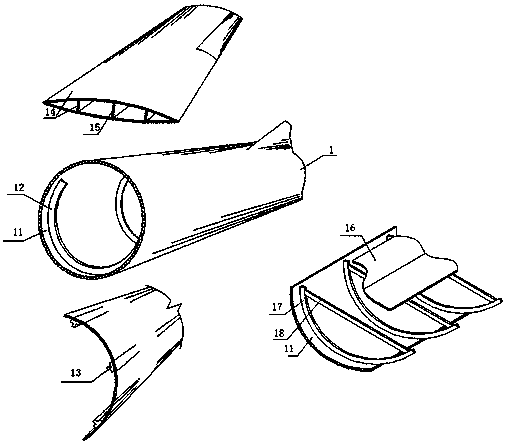

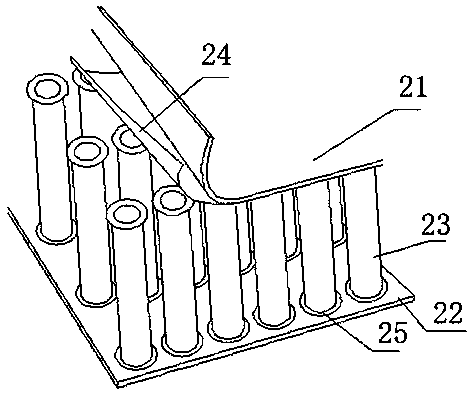

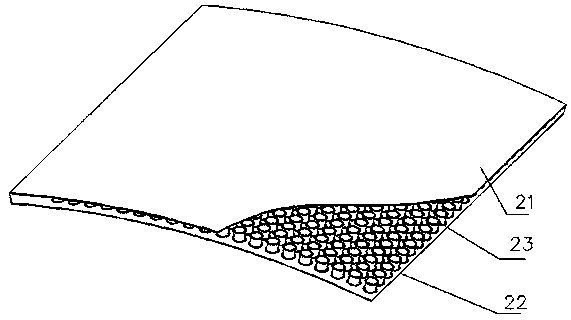

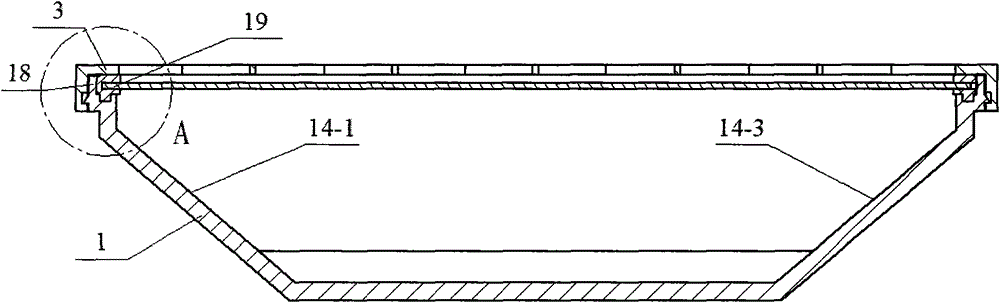

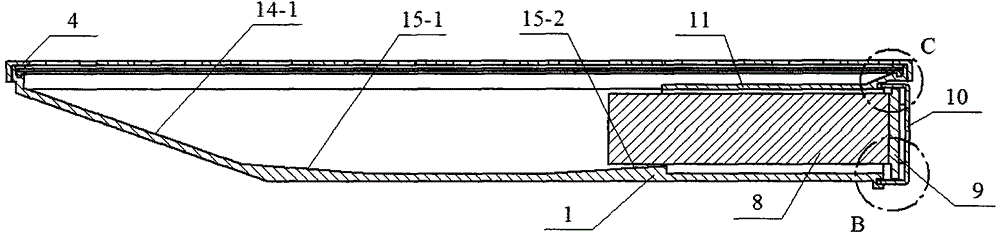

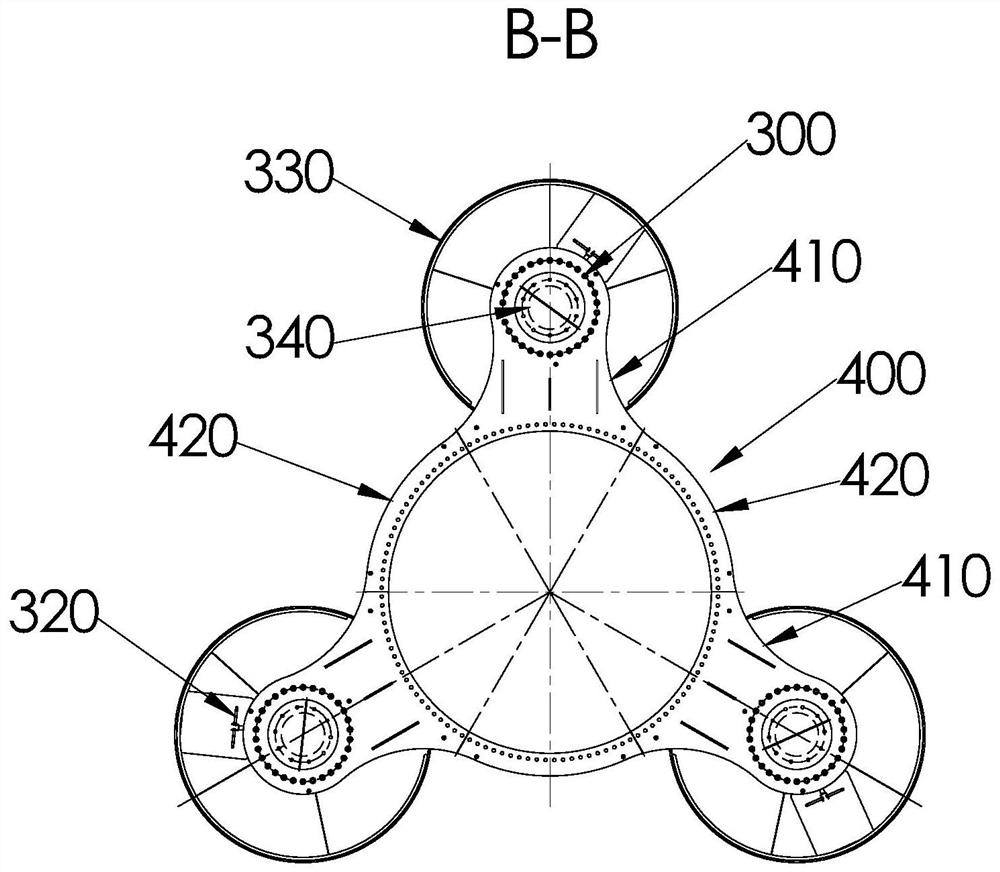

Aerial vehicle structure

An air vehicle structure comprises a framework structure and a skin connected with the framework structure, wherein at least one of the framework structure and the skin is made of plate metal; the plate metal comprises a first panel, a second panel as well as a plurality of hollow tubes arranged between the first panel and the second panel, and brazing layers are arranged between the hollow tubesand the first panel as well as between the hollow tubes and the second panel; a turning edge is arranged at at least one end of the hollow tubes. The aerial vehicle structure has the advantages of being small in self-weight, high in strength, stable in structure, high in impact resistance, capable of insulating sound and reducing noise, resistant to high temperature, corrosion and vibration, longin service life, capable of being carried and spliced and the like.

Owner:张跃

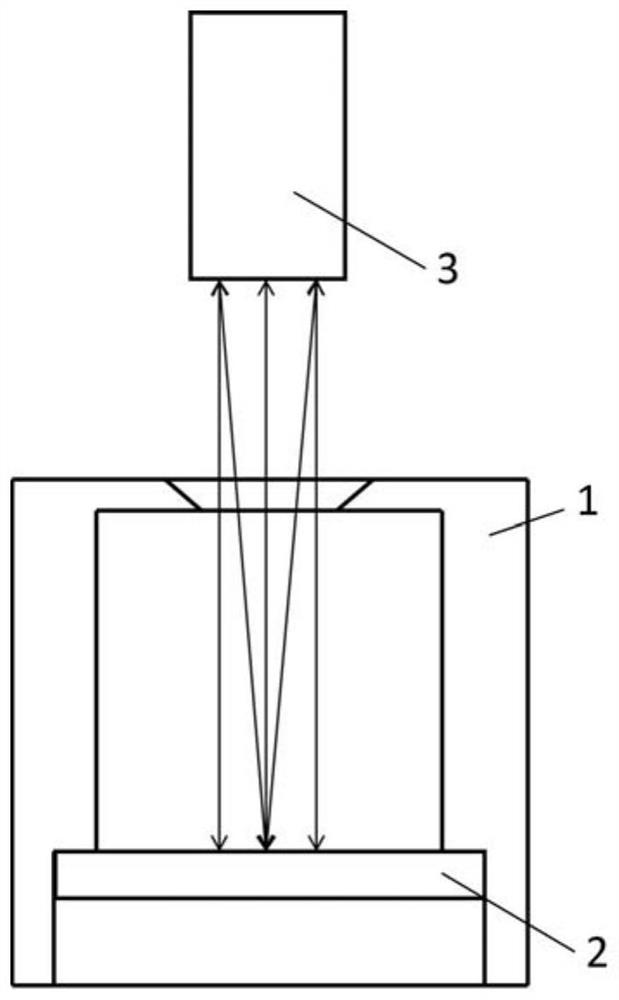

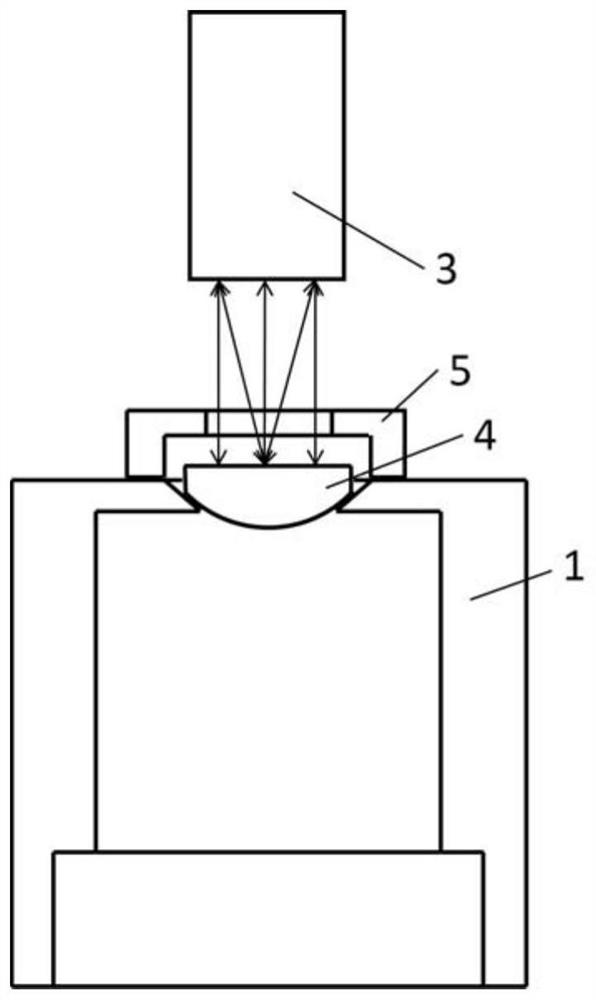

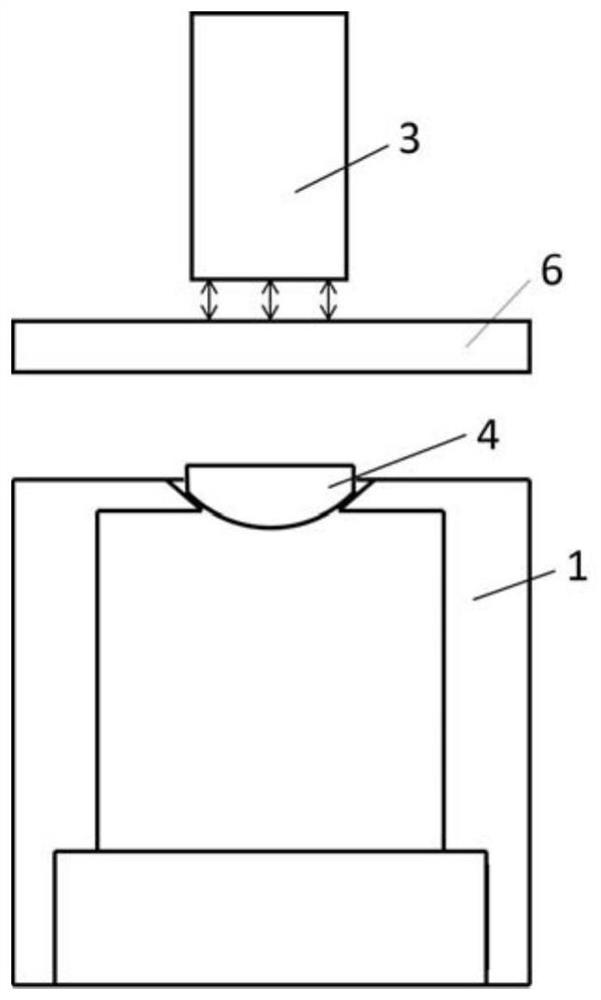

Alpha and beta ray detector

ActiveCN104865592ASimplify the assembly processShort assembly cycleX/gamma/cosmic radiation measurmentSilica gelFlash light

The present invention relates to a ray detector and particularly relates to an alpha and beta ray detector with the form of the combination of a thin plastic scintillator and a photomultiplier tube. Through the structural design, external photons are avoided from entering into the detector as far as possible, the inner surface light collection efficiency of the detector is improved, and the ray transmission area of a detection window is increased. The light shielding of the detection window is mainly rely on the elastic contact of a black silicone ring with the plastic scintillator, a light shielding film, a shell side wall and a protection cover. The inner surface of a detector shell is coated with an aluminium film, thus the flashing light reflection factor is larger than 0.9, the four walls of the detector shell are designed to be slopes, the reflection times of the flashing light in the detector shell is reduced, and thus the photons can be gathered quickly. The shield grids of the detection window have two forms, one is a honeycomb hexagonal grid, the transmittance of ray vertical incidence is larger than 90%, the other one is the combination of a hexagonal grid with a stainless steel gauze, and the transmittance of the ray vertical incidence is larger than 75%. The detector has the advantages of simple structure, high maintainability and high detection efficiency.

Owner:中国人民解放军63973部队

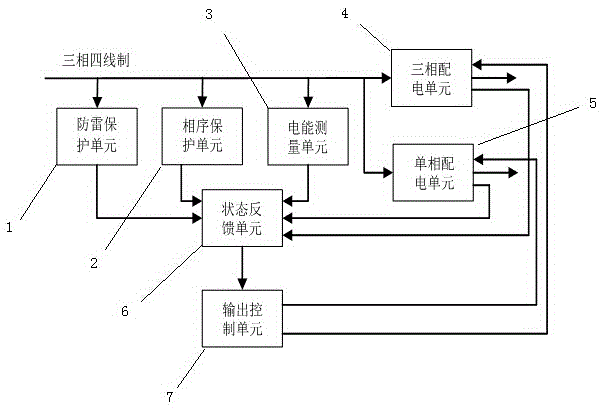

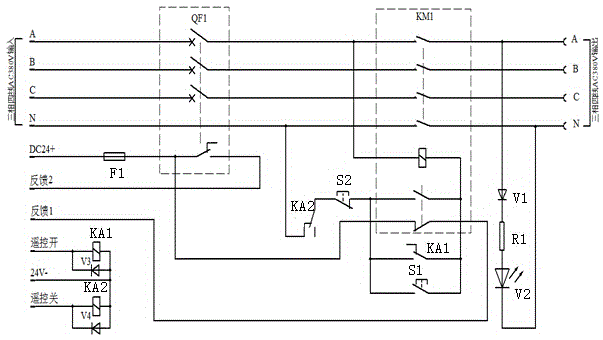

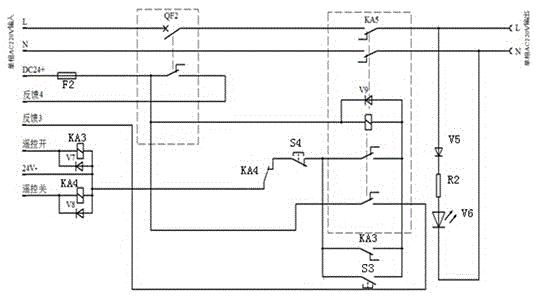

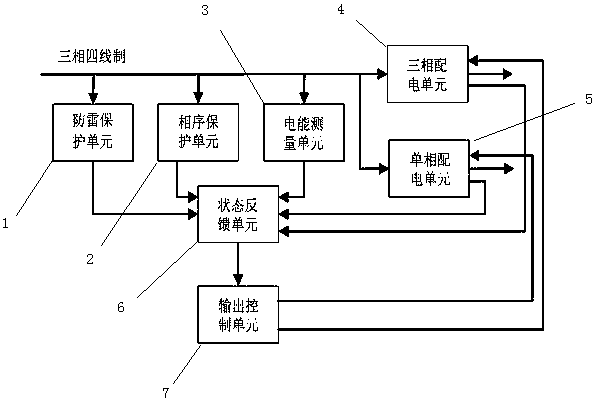

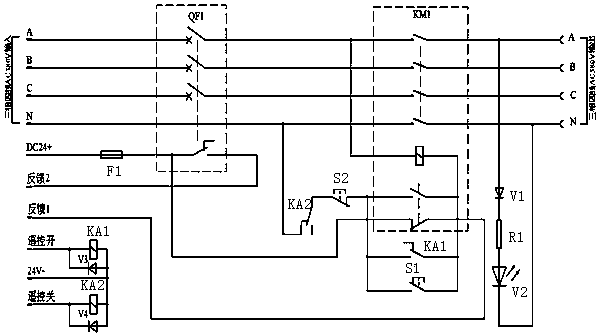

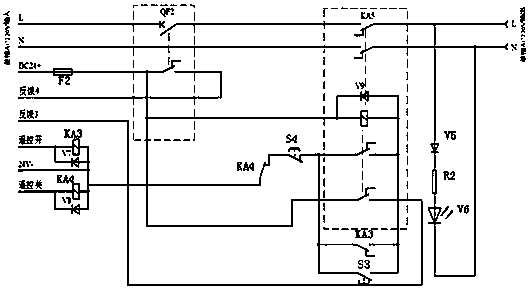

Radar intelligent power distribution system

ActiveCN105470930ARealize the control functionRealize the remote control functionEmergency protective circuit arrangementsInformation technology support systemDistribution power systemControl unit

The present invention relates to a radar intelligent power distribution system. The system comprises a lightning protection unit, a phase sequence protection unit, an electrical energy measurement unit, a three-phase power distribution unit, a single-phase power distribution unit, a state feedback unit and an output control unit. The input ends of the lightning protection unit, the phase sequence protection unit, the electrical energy measurement unit, the three-phase power distribution unit and the single-phase power distribution unit are connected to the three-phase four-wire end of a power network; the output ends of the lightning protection unit, the phase sequence protection unit, the electrical energy measurement unit, the three-phase power distribution unit and the single-phase power distribution unit are connected to the input end of the state feedback unit; the output end of the state feedback unit is connected to the input end of the output control unit; and the control end of the output control unit is connected to the input ends of the three-phase power distribution unit and the single-phase power distribution unit. The radar intelligent power distribution system is diverse in control mode, better in real-time monitoring property, safe and reliable. The modular design is used, therefore functions of unit modules are clear, and fault maintenance and component replacement are more convenient.

Owner:ECU ELECTRONICS INDAL

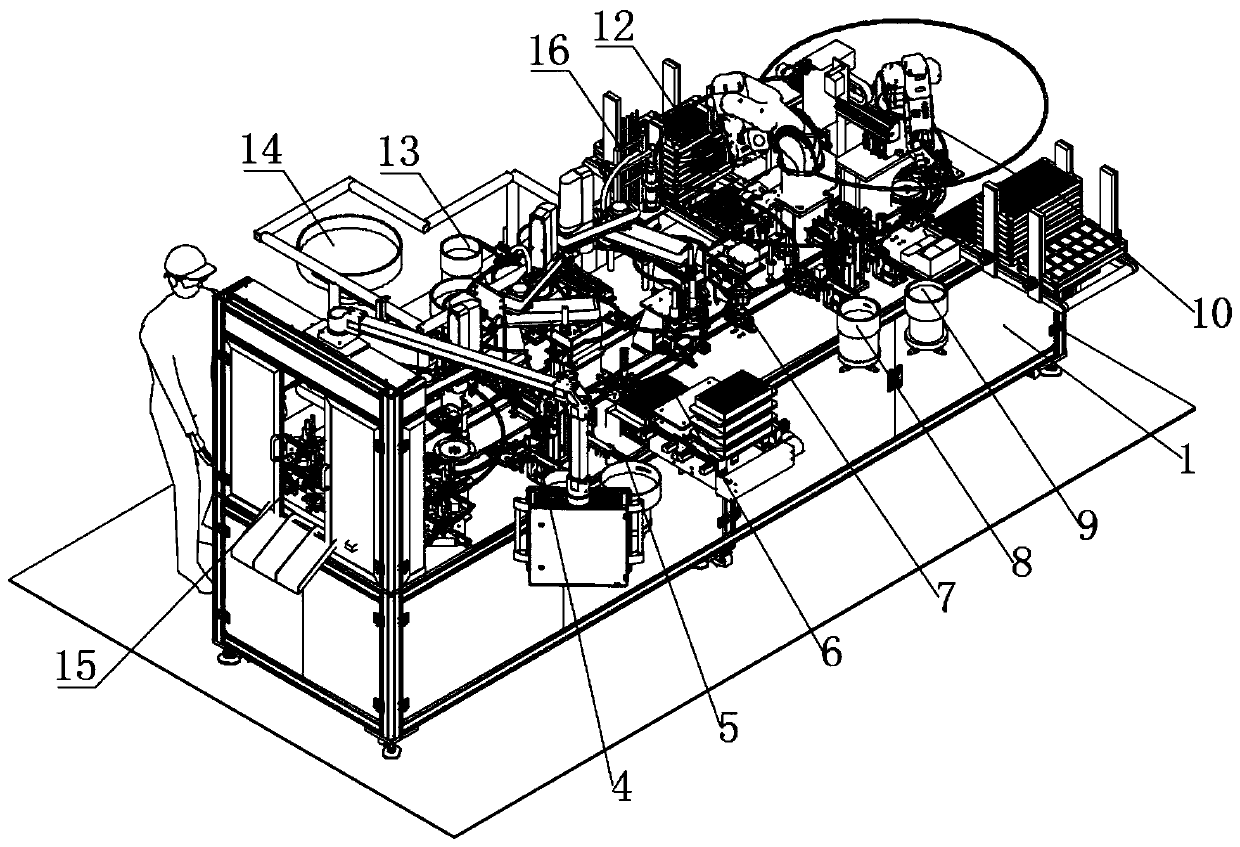

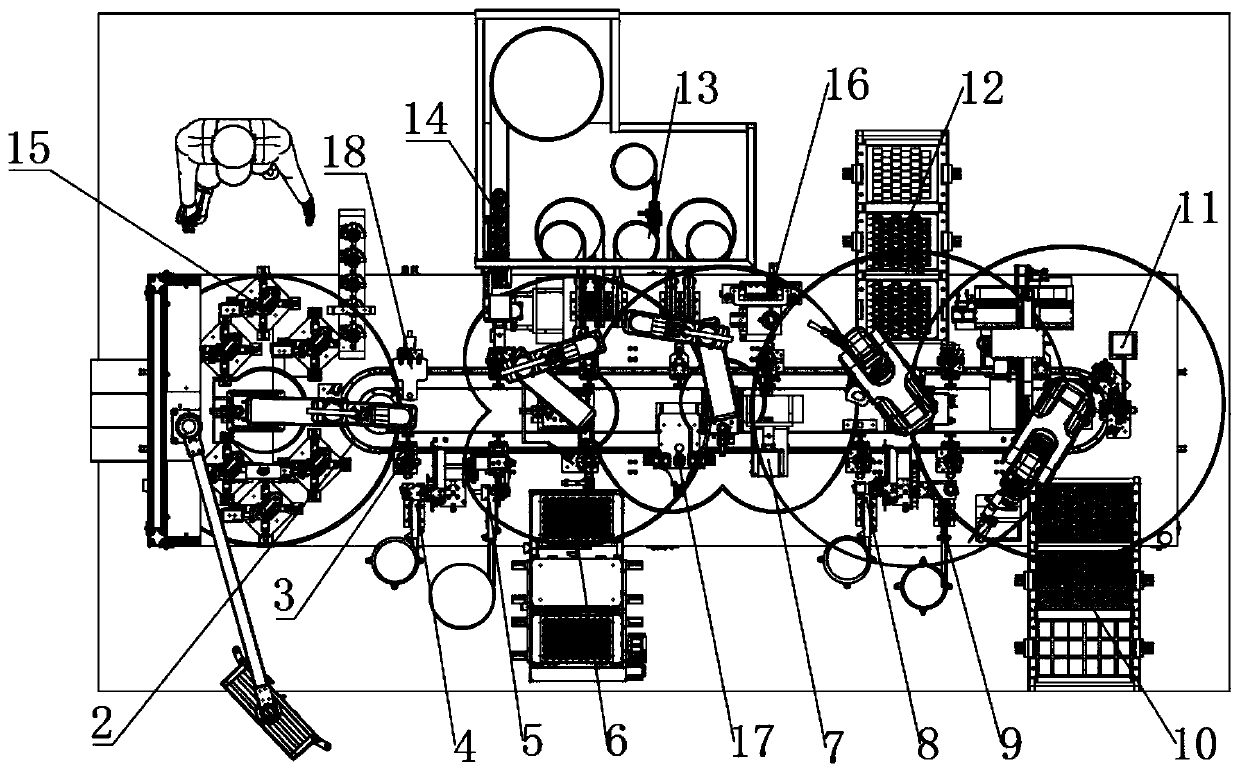

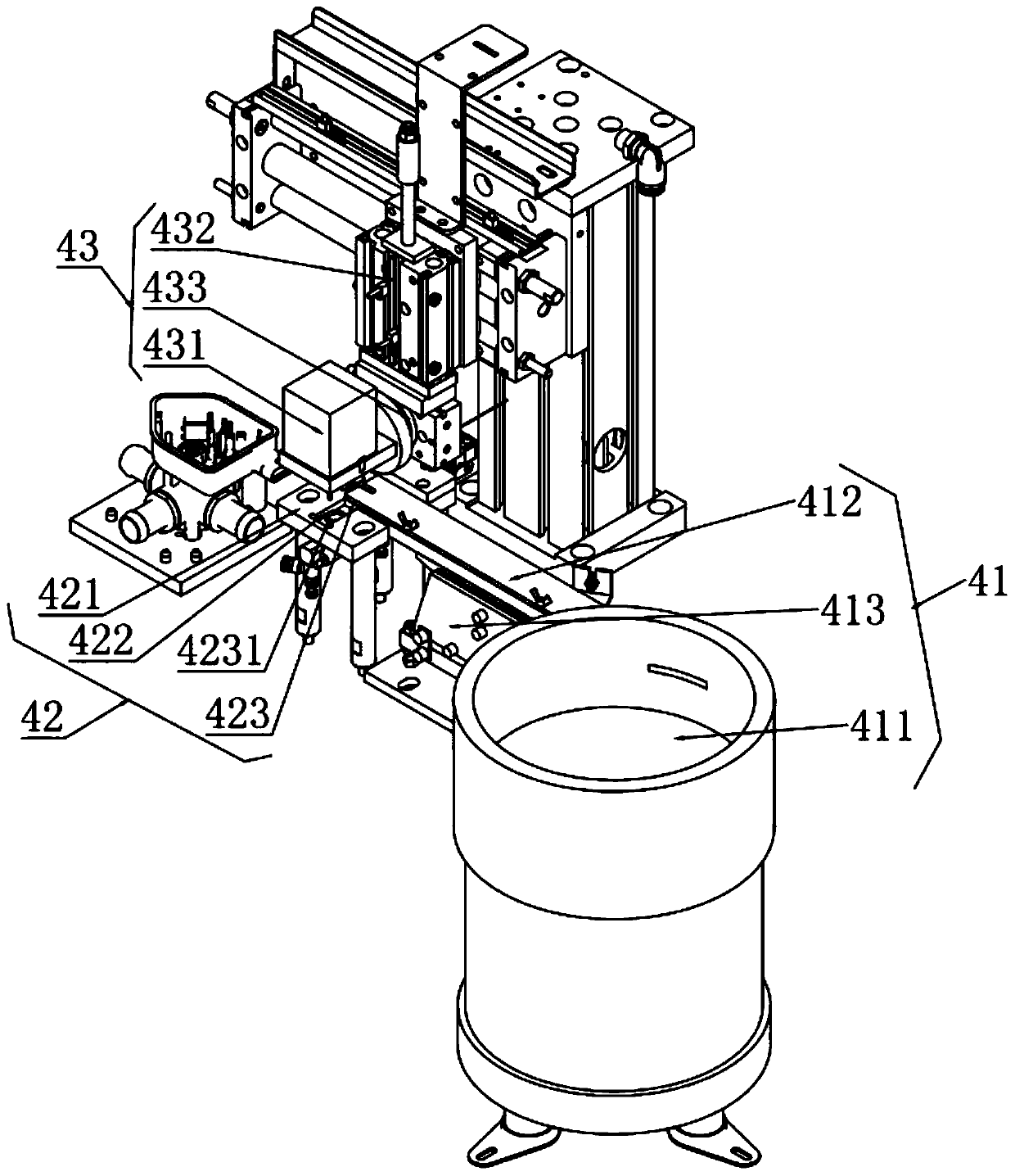

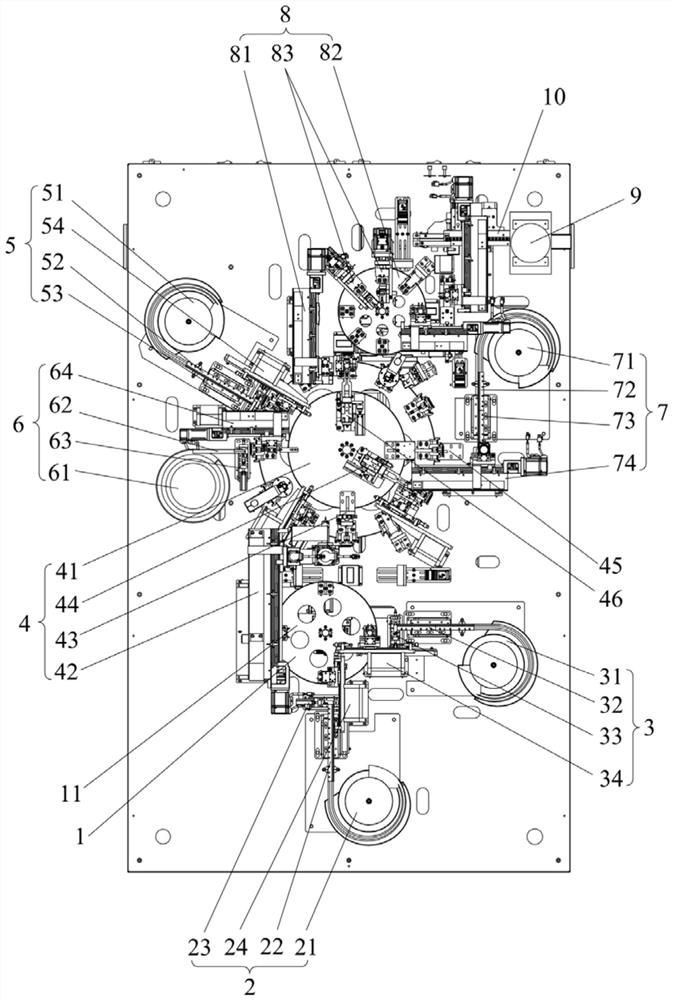

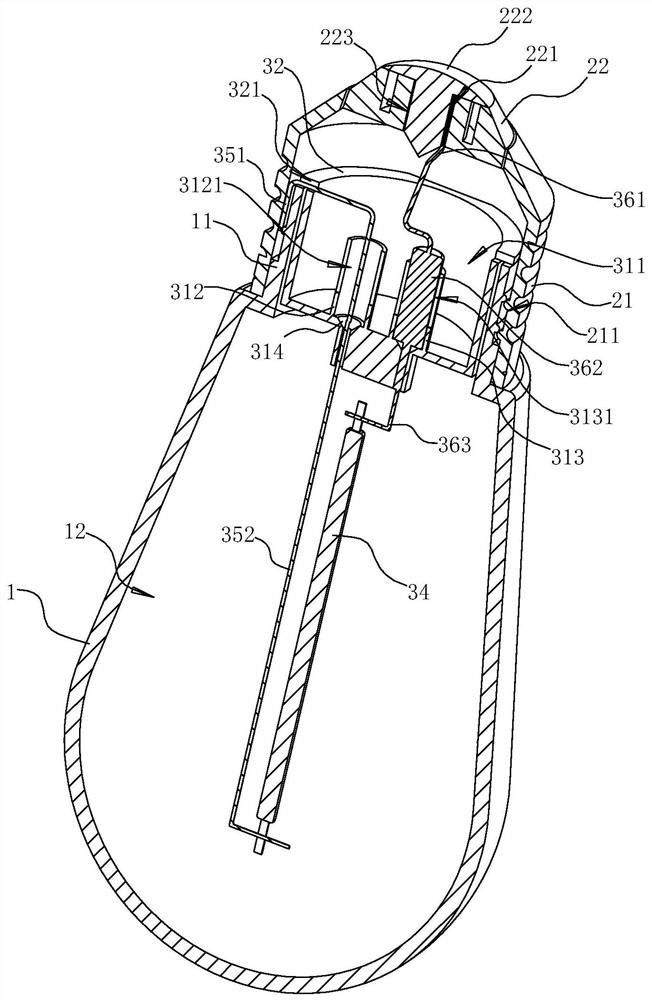

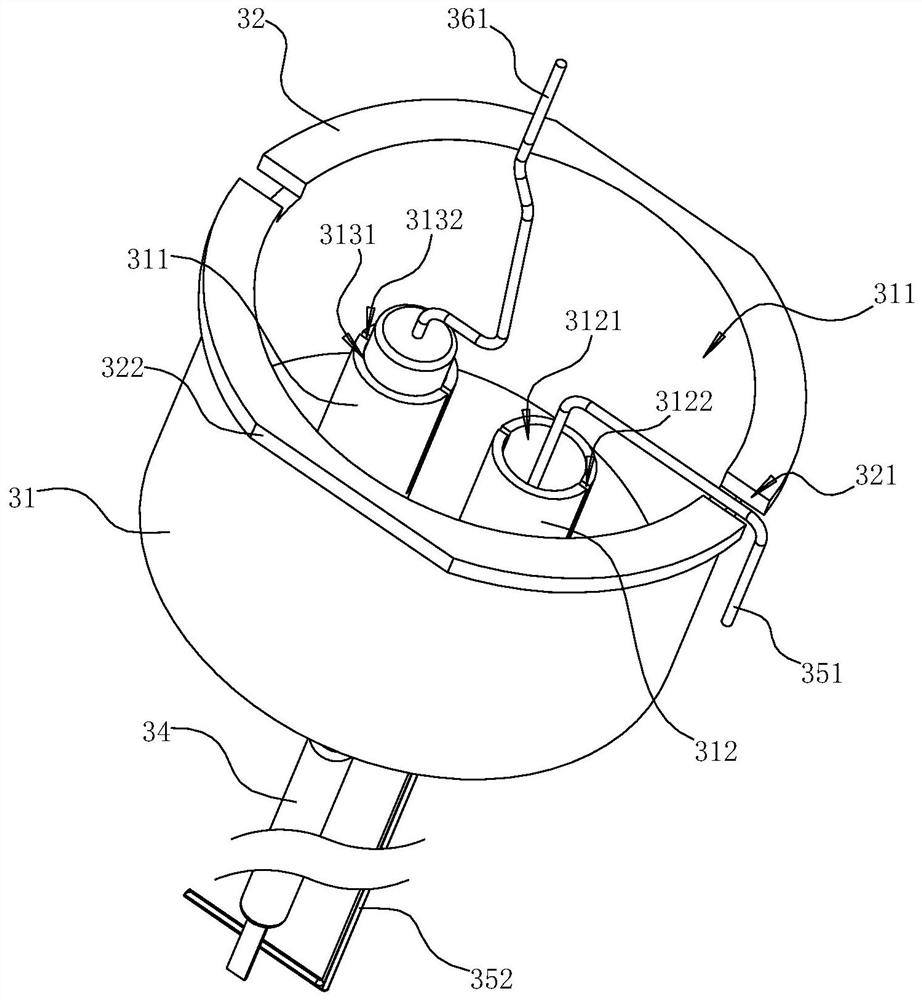

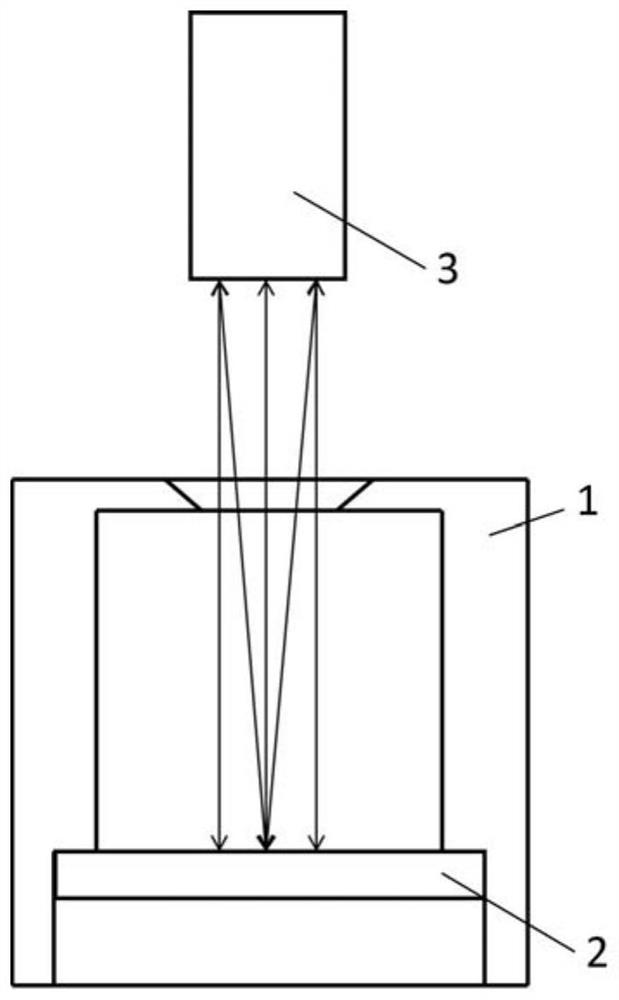

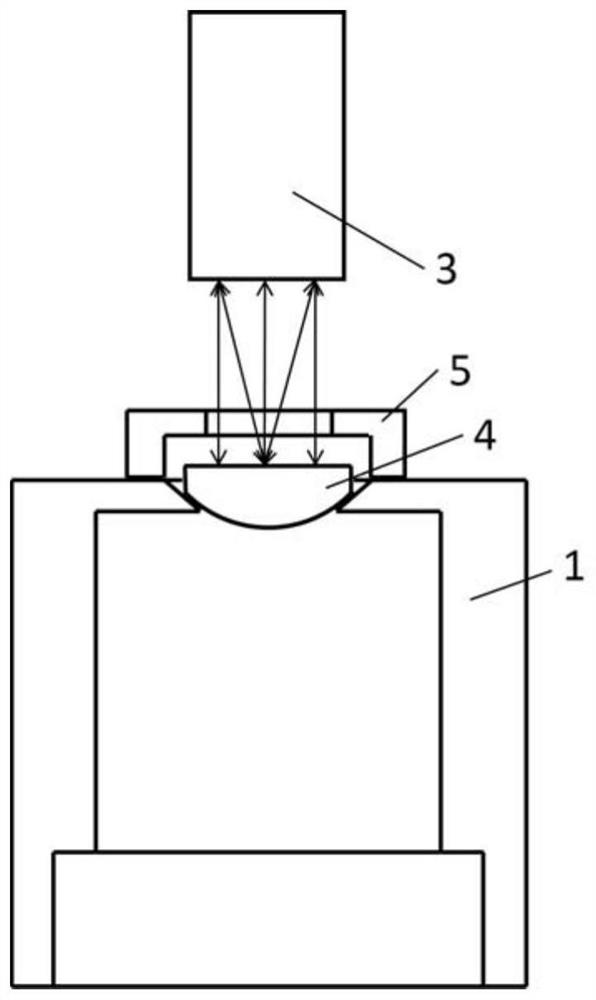

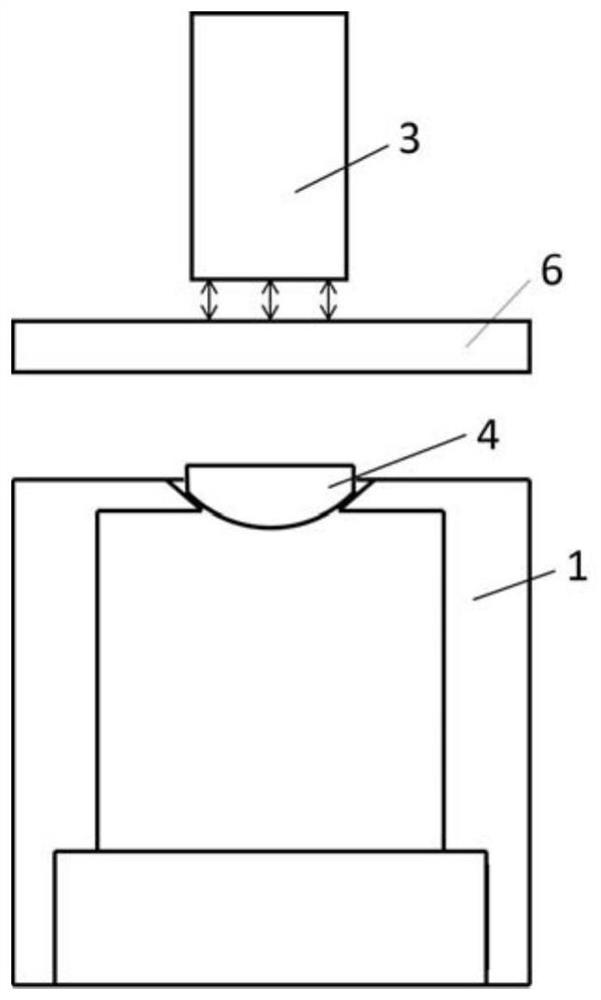

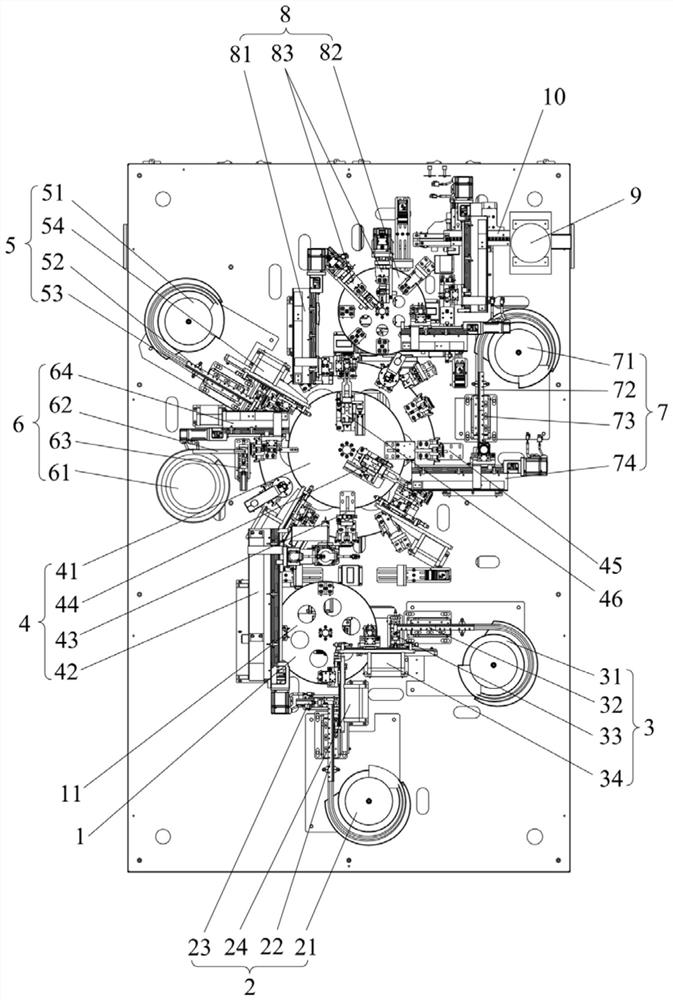

Automatic assembly equipment for water valve

PendingCN111496521AHigh degree of automationShort assembly cycleAssembly machinesMetal working apparatusGear wheelElectric machinery

The invention relates to the technical field of mechanical automatic assembly and discloses automatic assembly equipment for a water valve. The automatic assembly equipment for the water valve comprises a box-type rack. A rotary conveying table is arranged on the box-type rack, a positioning jig of an electronic water valve body is arranged on the rotary conveying table, and a first sealing ring assembly station, a side leather collar assembly station, a valve element assembly station, a round cover welding station, a second sealing ring assembly station, a plug assembly station, a PCB assembly station, a laser coding station, a motor assembly station, a gear assembly station, a bottom cover welding station and a comprehensive performance detection station are sequentially arranged along the rotary conveying table. The rotary conveying table drives the positioning jig to move to convey the electronic water valve to all the stations for assembly. The assembly equipment is compact in structure and small in occupied area, and the assembly efficiency and the assembly yield are remarkably improved.

Owner:杭州中久自控系统有限公司

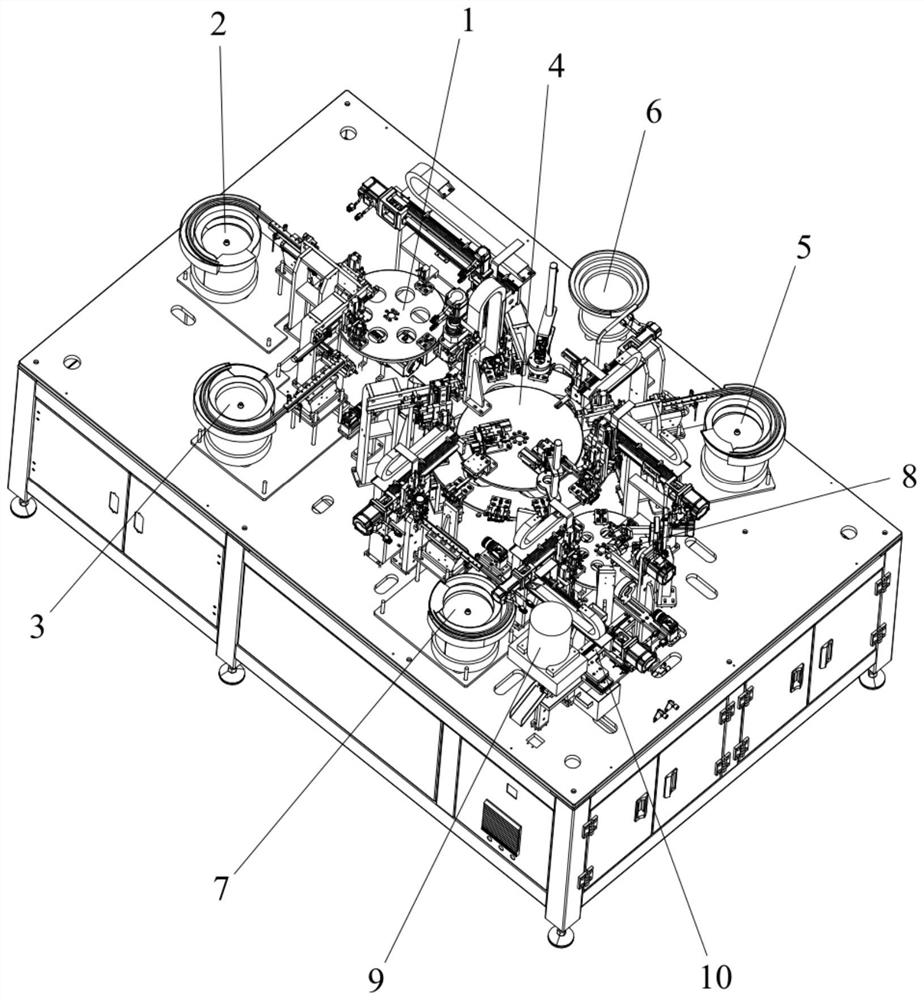

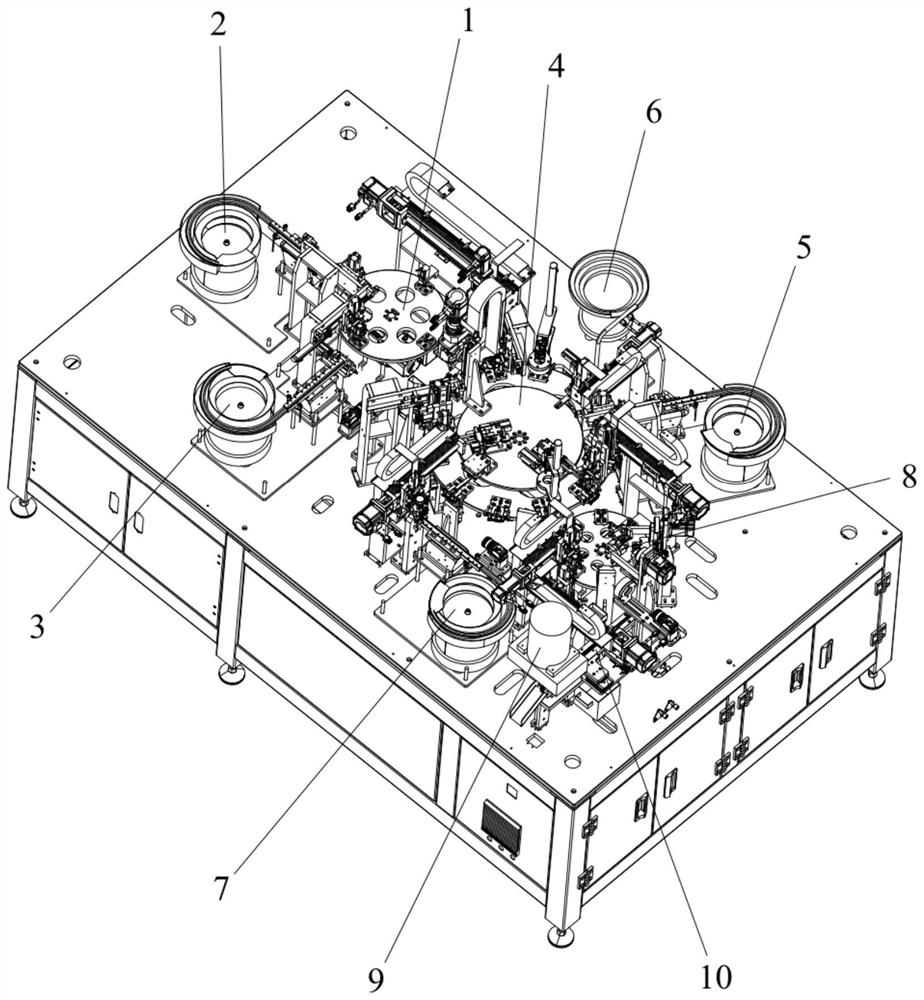

Automatic assembly equipment

ActiveCN112975375AReduce human errorHigh degree of automationAssembly machinesProcess engineeringTransfer mechanism

The invention relates to the field of automatic assembly, and discloses automatic assembly equipment. A large part and a small part are pre-assembled into a first semi-finished product through first jigs on a first index plate, a shell and a spring are pre-assembled into a second semi-finished product through second jigs on a second index plate, and the first semi-finished product on the first index plate is transferred to the second index plate through a first transfer mechanism; the first semi-finished product and the second semi-finished product are pressed into a third semi-finished product through a first press-fitting mechanism, clamping hooks are conveyed to the second index plate through a clamping hook feeding module, and the clamping hooks and the third semi-finished product are pressed into a fourth semi-finished product through a second press-fitting mechanism; and the fourth semi-finished product on the second index plate is transferred to a third index plate through a second transfer mechanism, the fourth semi-finished product on the third index plate is subjected to an action test through an action test mechanism, the fourth semi-finished product which is qualified after the action test is oiled into a finished product through an oiling module, and the whole assembly process is high in automation degree, small in personal error and high in assembly efficiency.

Owner:昆山经坤自动化科技有限公司

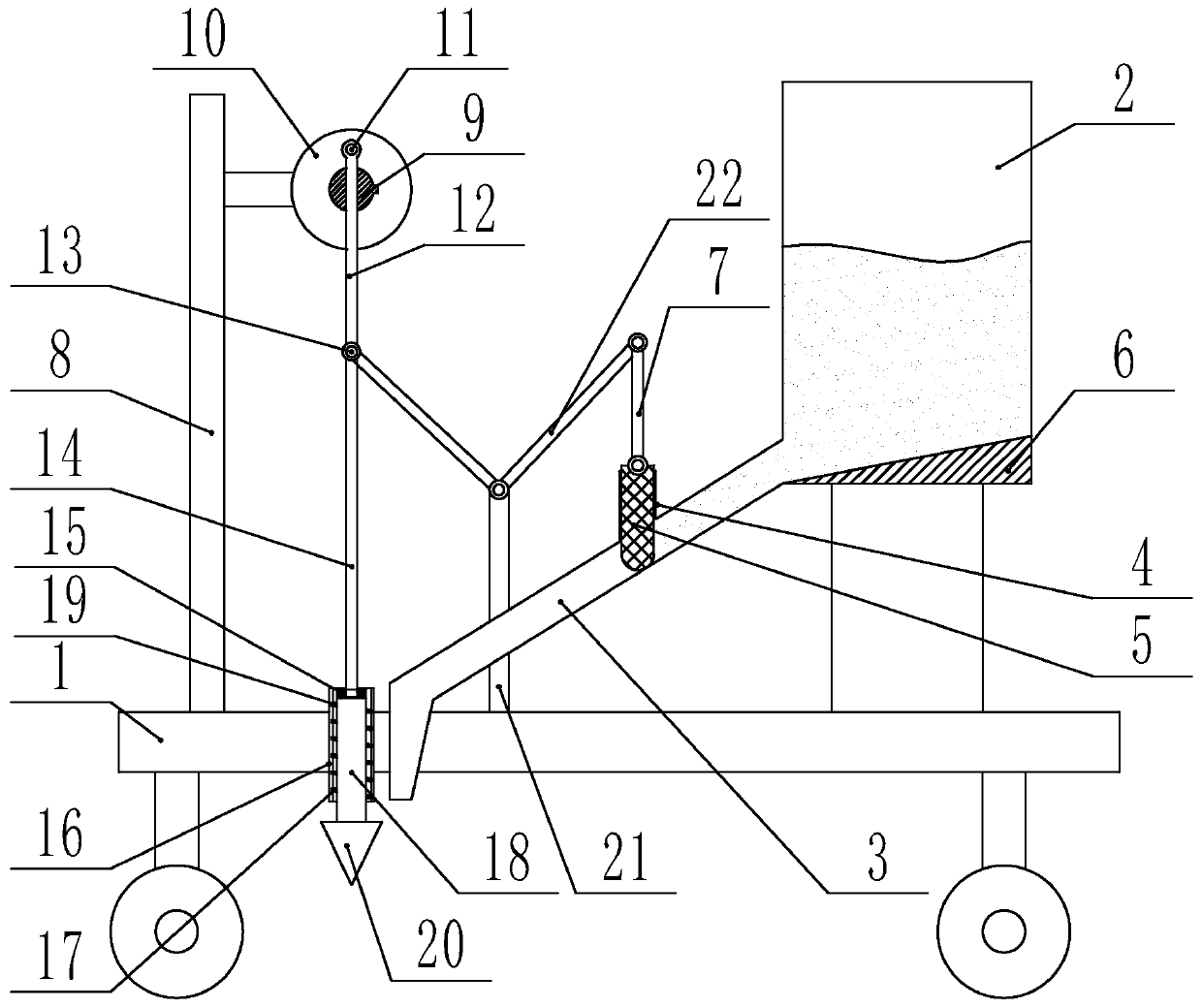

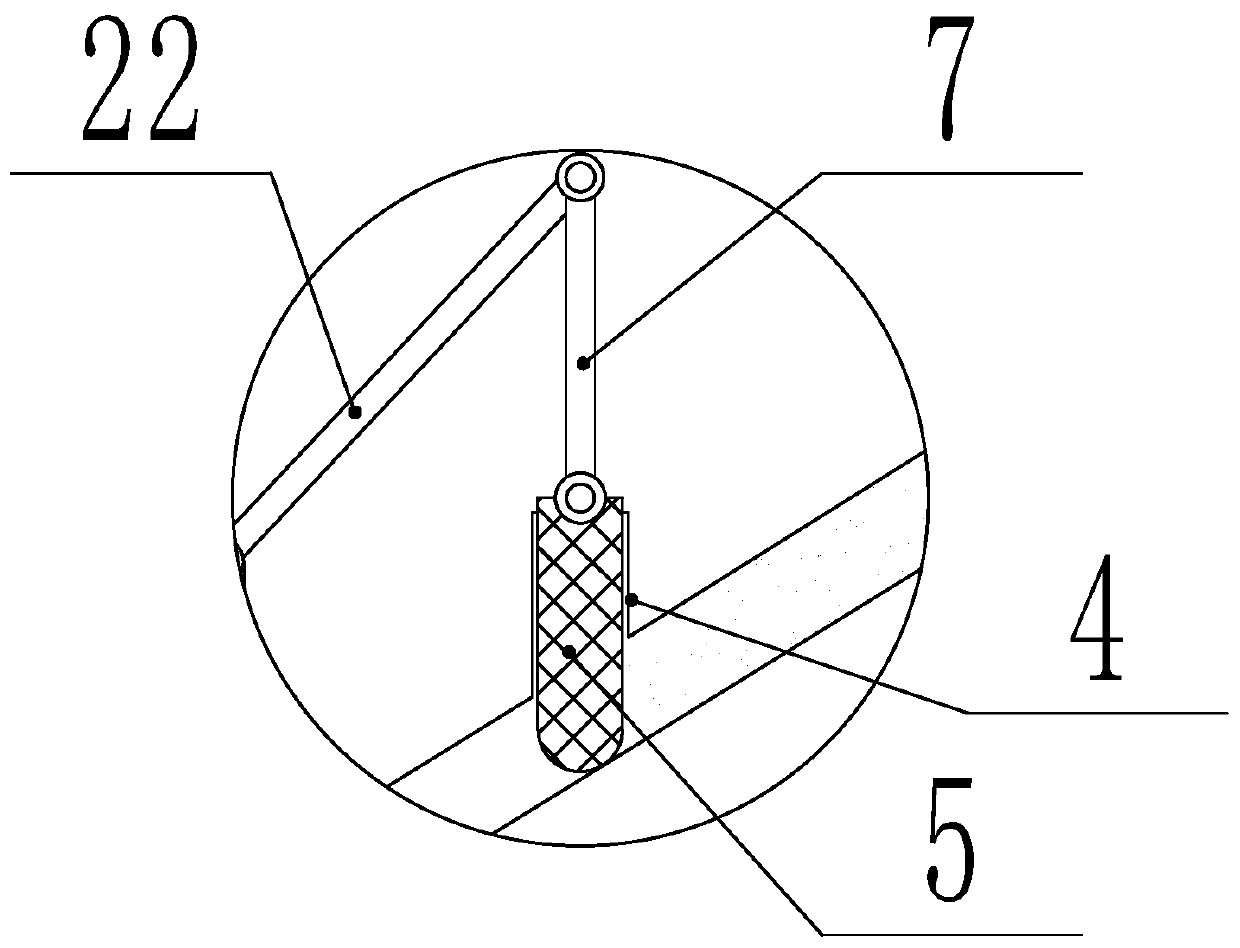

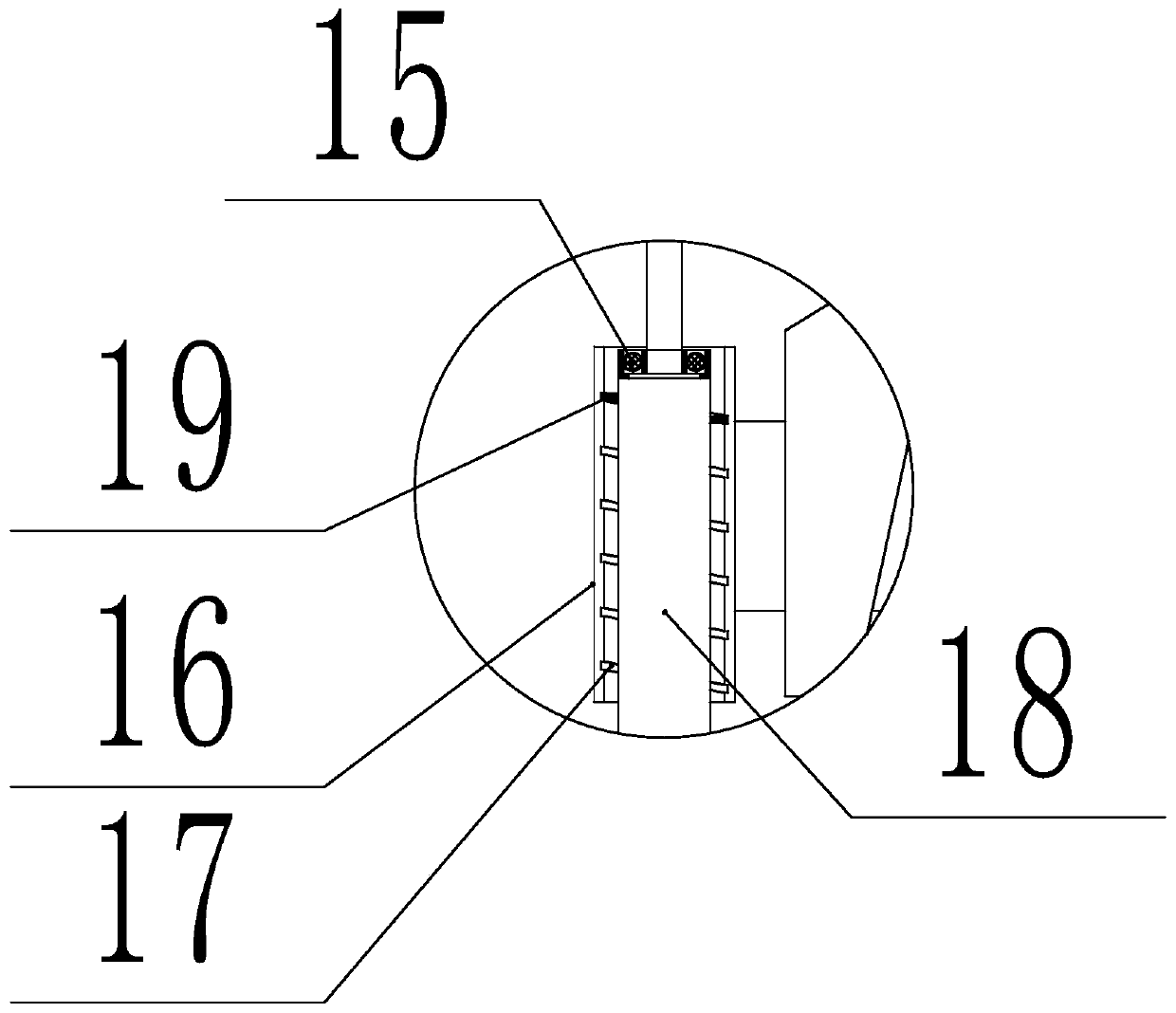

Corn seeding device for agricultural machinery

InactiveCN111201859AReduce power consumptionImprove work efficiencyPlantingDibble seedersAgricultural engineeringElectric machinery

The invention discloses a corn seeding device for agricultural machinery. The corn seeding device comprises a plate trailer, wherein a charging barrel is fixedly mounted on the plate trailer, a conveying pipe is arranged at the lower end of the charging barrel, the port of one end of the conveying pipe obliquely downwards penetrates through the plate trailer, a vertical pipe is arranged on the conveying pipe and communicates with the conveying pipe, an end cap is arranged in the vertical pipe, and a pull rod is movably connected with one end of the end cap; a motor mounting frame is arranged on the plate trailer, a motor is mounted on the motor mounting frame, a rotating disc is fixedly mounted on the rotating shaft of the motor, a stand column is arranged on the surface of the rotating disc, the stand column is movably connected with one end of the connecting rod, the other end of the connecting rod is movably connected with a rotating shaft, the rotating shaft is movably connected with one end of a push rod, and the other end of the push rod is connected with a drilling mechanism through a bearing. The corn seeding device has the beneficial effects of simple structure and low usecost.

Owner:黑龙江省农业科学院畜牧兽医分院

Method for precisely assembling space remote sensing camera body structure

InactiveCN101571389BImprove the state of stressImprove assembly accuracyPicture taking arrangementsEngineering

The invention provides a method for precisely assembling a space remote sensing camera body structure, belonging to the technical field of assembly connection of body equipment. The method is to use aglue film as the close loop size of body assembly, lead assembly precision and assembly stress to depend on the deflection of the glue film, cancel the pad which may generate larger error, change theassembly mode of a transition component from glue connection first and screwed connection second of mechanical connection method into screwed connection first and glue connection second, use the metal pad to be wound on the transition component to be closely matched with an inner hole of a strut, and better achieve the aims of small assembly stress, high assembly precision and steady and firm structure through a microstress glue connection method. The glue connection method reduces the stress of the body structure on sensitive orientation, namely on axial of the strut, and optimizes the stress status of the body. Meanwhile, the method has simple and convenient operation, short assembly period and low cost, and overcomes the defects of long period and high cost of the prior assembly methodby finishing the pad.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

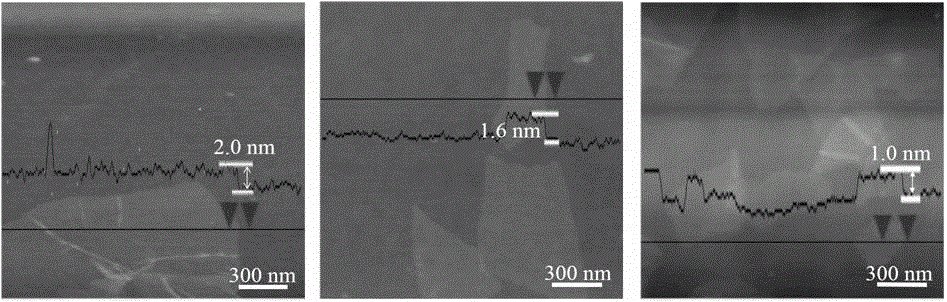

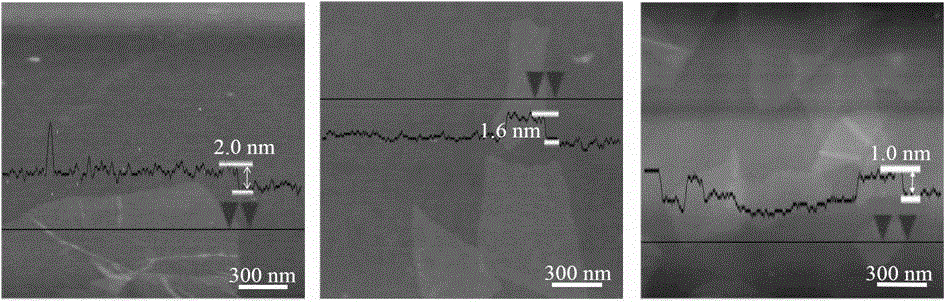

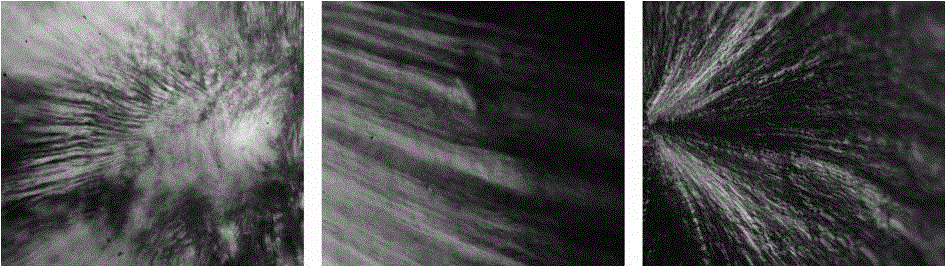

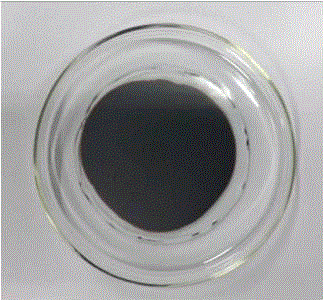

Preparation method of graphene oxide sheet with different layers/liquid crystal/film

The present invention belongs to the technical field of graphene oxides, and specifically discloses a preparation method of a graphene oxide sheet with different layers / liquid crystal / film. The preparation method comprises: dispersing graphite oxide in a solvent, carrying out an ultrasound treatment, carrying out centrifugation separation, extracting the lower layer liquid in the centrifugation tube every 0.5-3 h and labeling as a group of the samples until the supernatant is colorless and transparent, and removing the solvent from the sample so as to obtain the graphene oxide sheet; carrying out further centrifugation concentration on the graphene oxide sheet, taking the lower layer liquid, and removing the solvent to obtain a graphene oxide liquid crystal; and coating the graphene oxide liquid crystal onto a substrate in a dropwide manner, and drying at a temperature of 15-35 DEG C so as to obtain the graphene oxide film. According to the present invention, with the preparation method, the problems that the graphene oxide sheets with multiple layers, two layers and one layer can not be concurrently and precisely obtained and the liquid crystal phase preparation is complex in the prior art are solved; and the graphene oxide liquid crystal preparation is simple, the raw materials achieve the zero loss, the film assembly period is short, and the obtained film has the optical anti-counterfeiting capability, such that the obtained film has the good development prospects in the anti-counterfeiting field.

Owner:ZHENGZHOU UNIV

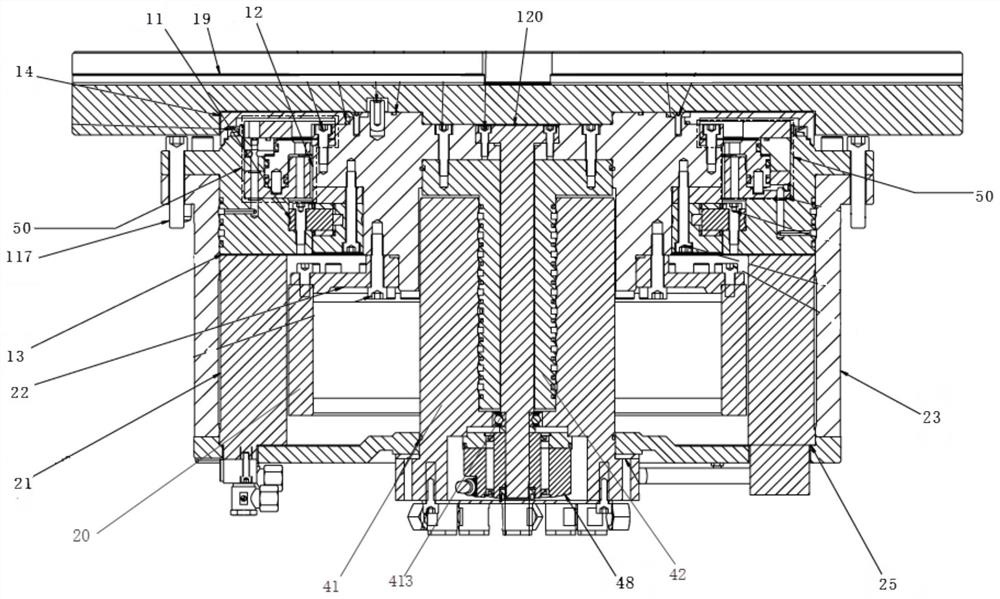

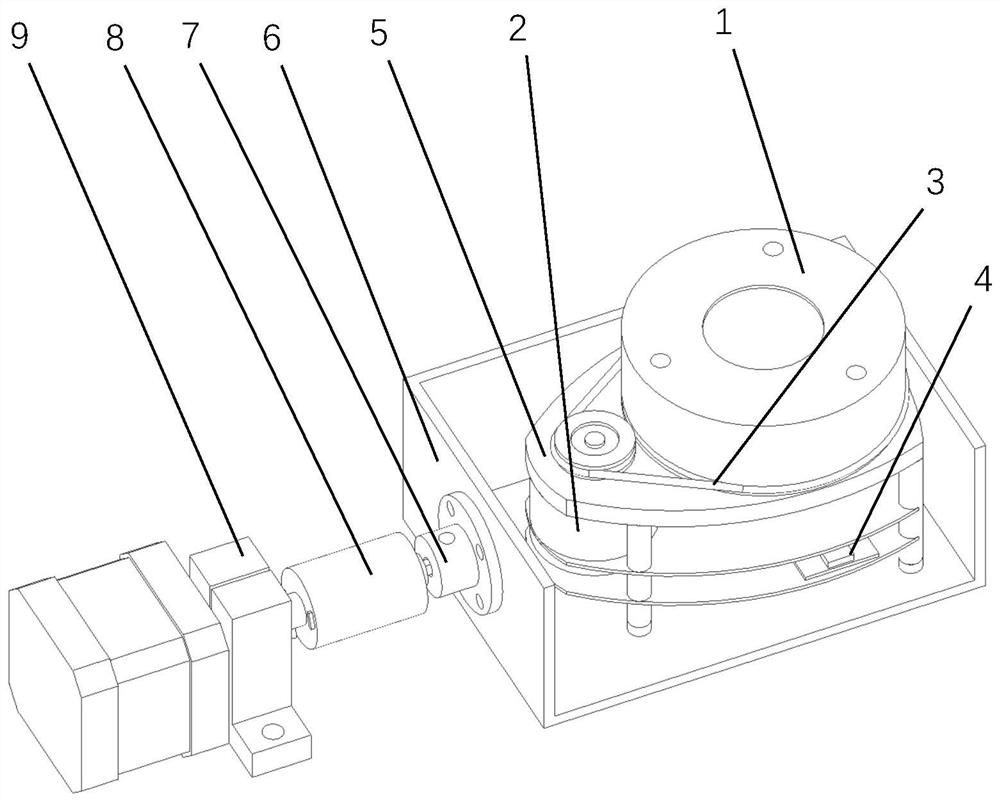

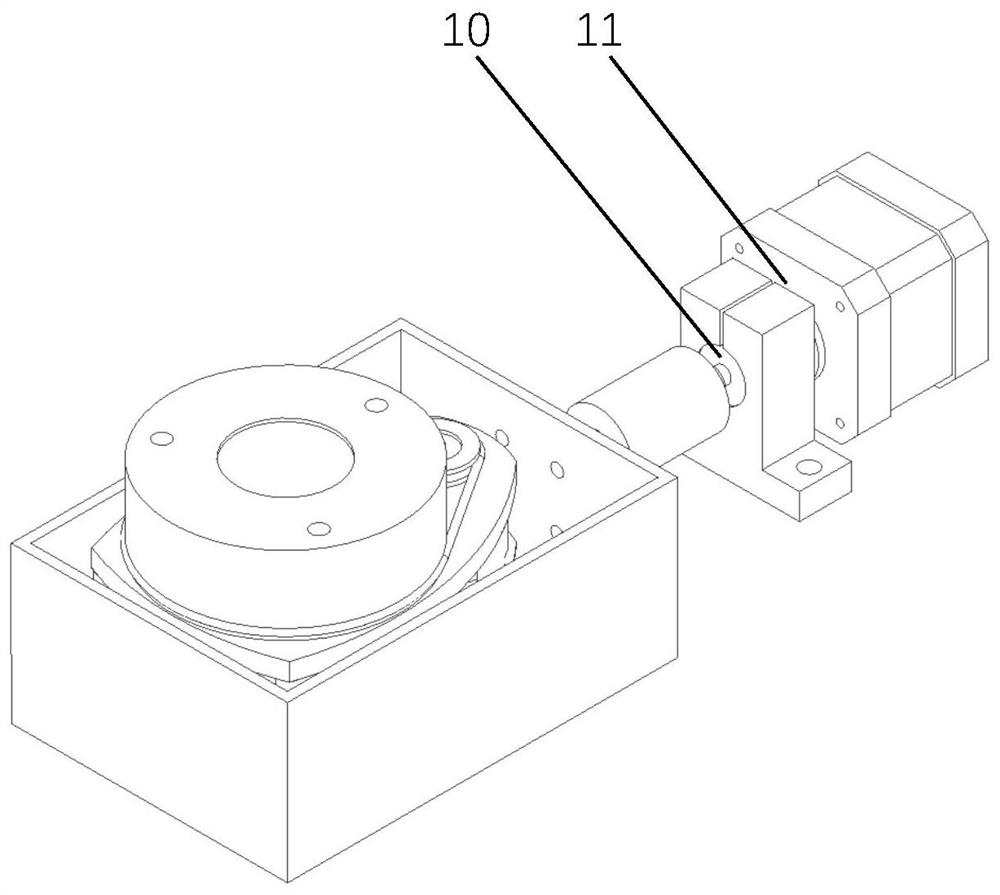

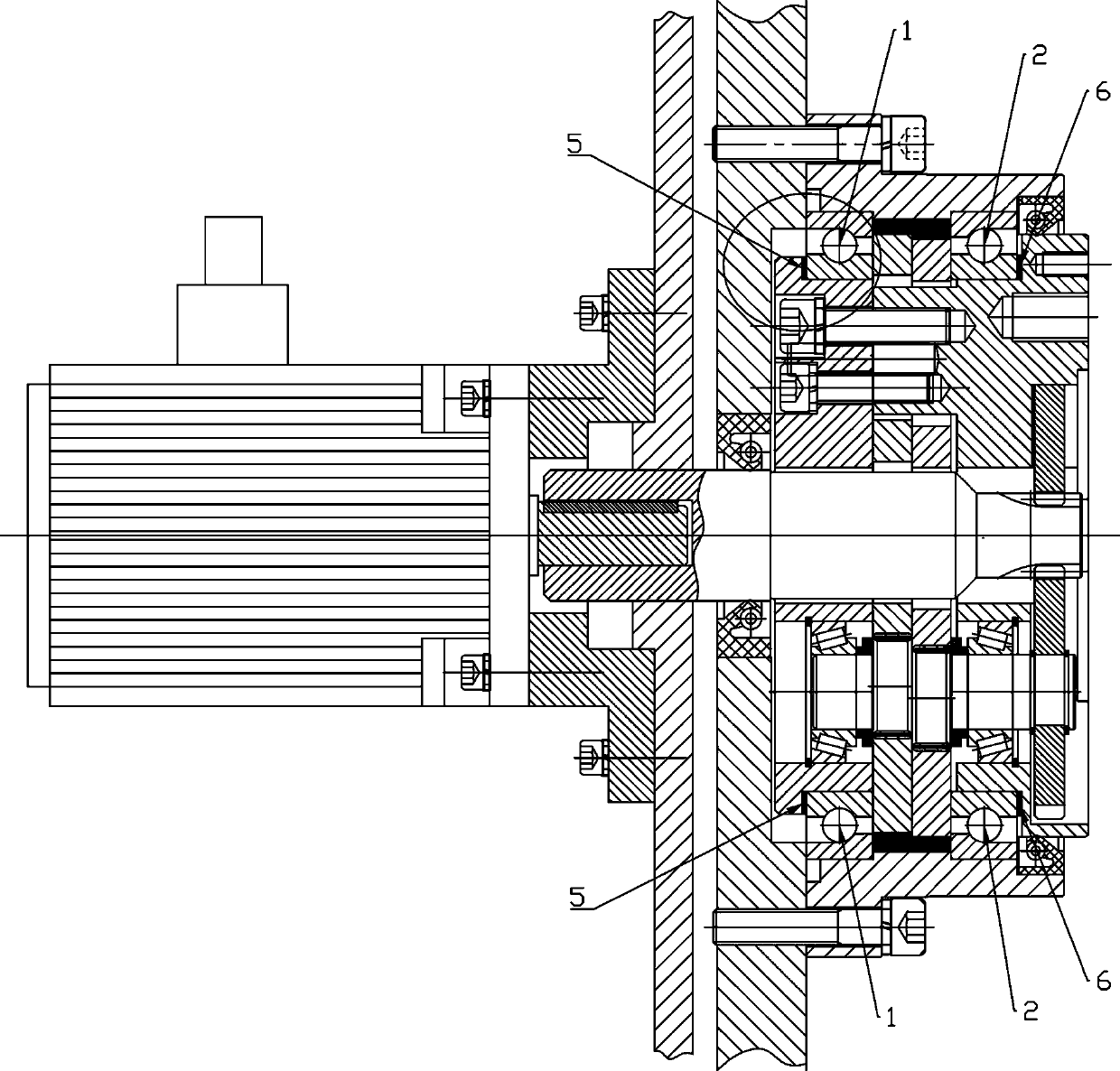

Direct drive type numerical control precision rotary table and machine tool

PendingCN114193177ANo wearNo transmission efficiency lossLarge fixed membersDriving apparatusNumerical controlControl engineering

The invention discloses a direct-drive numerical control precision rotary table and a machine tool, and the precision rotary table comprises a rotary table bearing, a rotary main shaft, a rotary table bearing seat, a rotor of a torque motor, a stator of the torque motor, a connecting flange plate, a rotary table, a connecting flange chassis and a bushing; a rotor of the torque motor is rigidly connected with the rotary main shaft through the connecting flange plate; an inner ring of the rotary table bearing is mounted on the rotary main shaft, and the rotary table is rigidly connected with the rotary main shaft; a stator of the torque motor is assembled and connected with the connecting flange chassis and the bushing; an outer ring of the rotary table bearing is installed on the rotary table bearing seat, and the rotary table bearing seat is in rigid connection with a lining of the fixed torque motor stator. The device is simple in structure, convenient to install and debug, short in assembly period, high in precision stability and convenient to repair and maintain.

Owner:上海赛卡精密机械有限公司

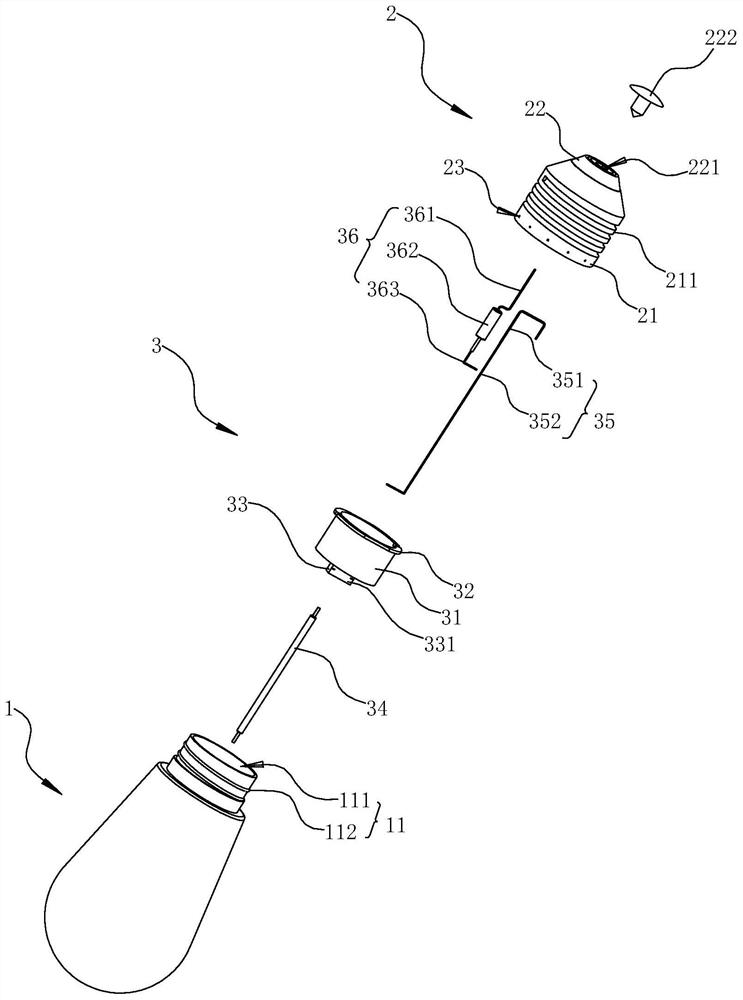

Bulb, bulb production equipment and bulb production process

InactiveCN113464855AEasy to assembleImprove the ease of assemblyAssembly machinesMetal working apparatusGuide wiresPhysics

Owner:SHENZHEN LANPUXIN TECH CO LTD

Multi-degree-of-freedom omnibearing laser radar

PendingCN113109826AImprove scanning efficiencyMeet the structural needs of different sizesElectromagnetic wave reradiationPoint cloudRadar

The invention discloses a multi-degree-of-freedom omni-directional laser radar which comprises a laser receiving and transmitting module, a direct current motor, a conveying belt, a data processing chip, a stable support, a radar module base, a flange coupling, a conductive slip ring, a bearing support, a bearing and a stepping motor. The structure is used for acquiring the environment point cloud and improving the scanning efficiency. By means of the detachable stepping motor and other components, the arrangement position can be adjusted within a certain range, and the requirements of structures of different sizes in engineering are met; and the assembly process is simple, the assembly period is short, and a large amount of manpower and time expenditure are saved.

Owner:BEIJING UNIV OF TECH

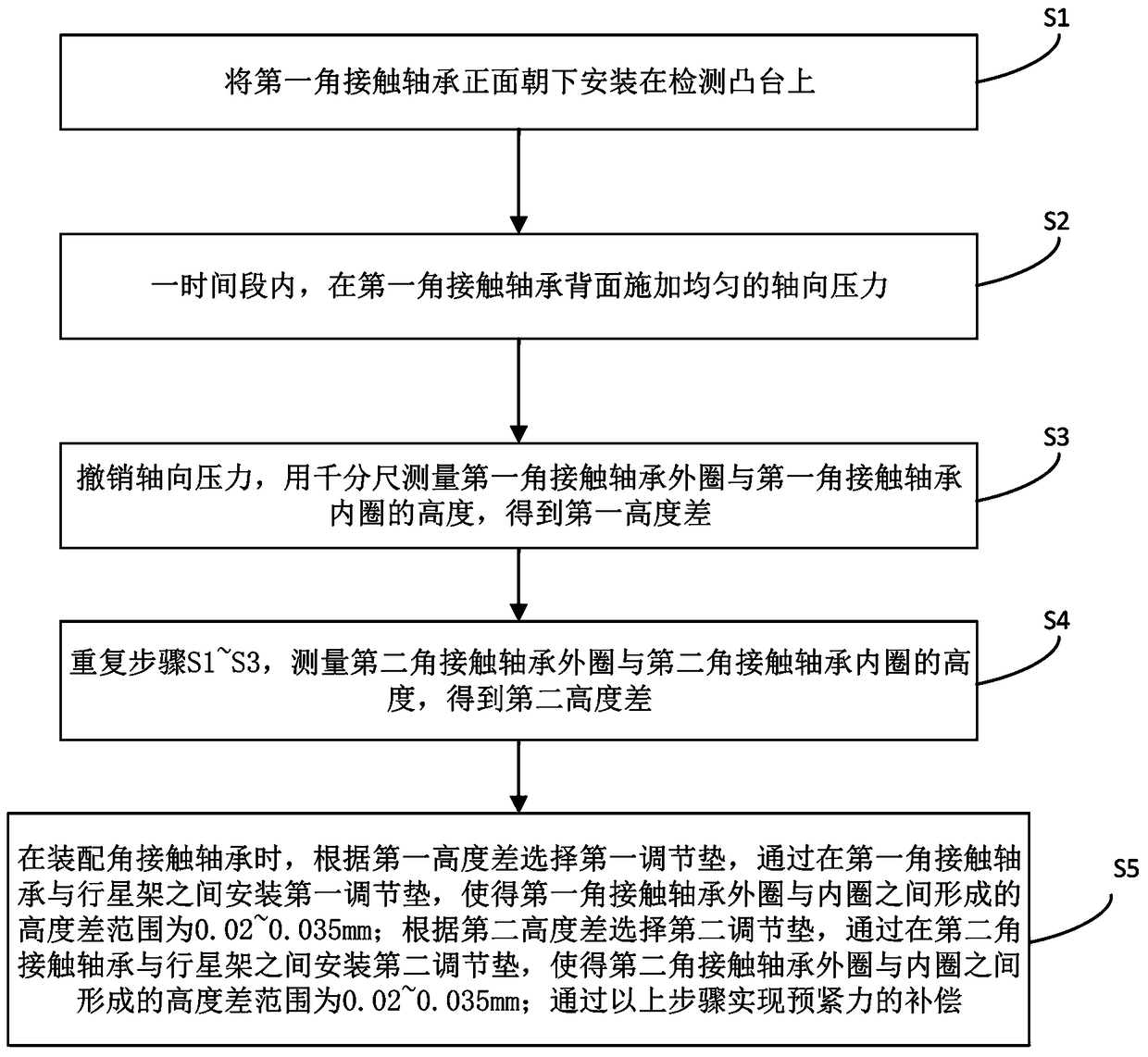

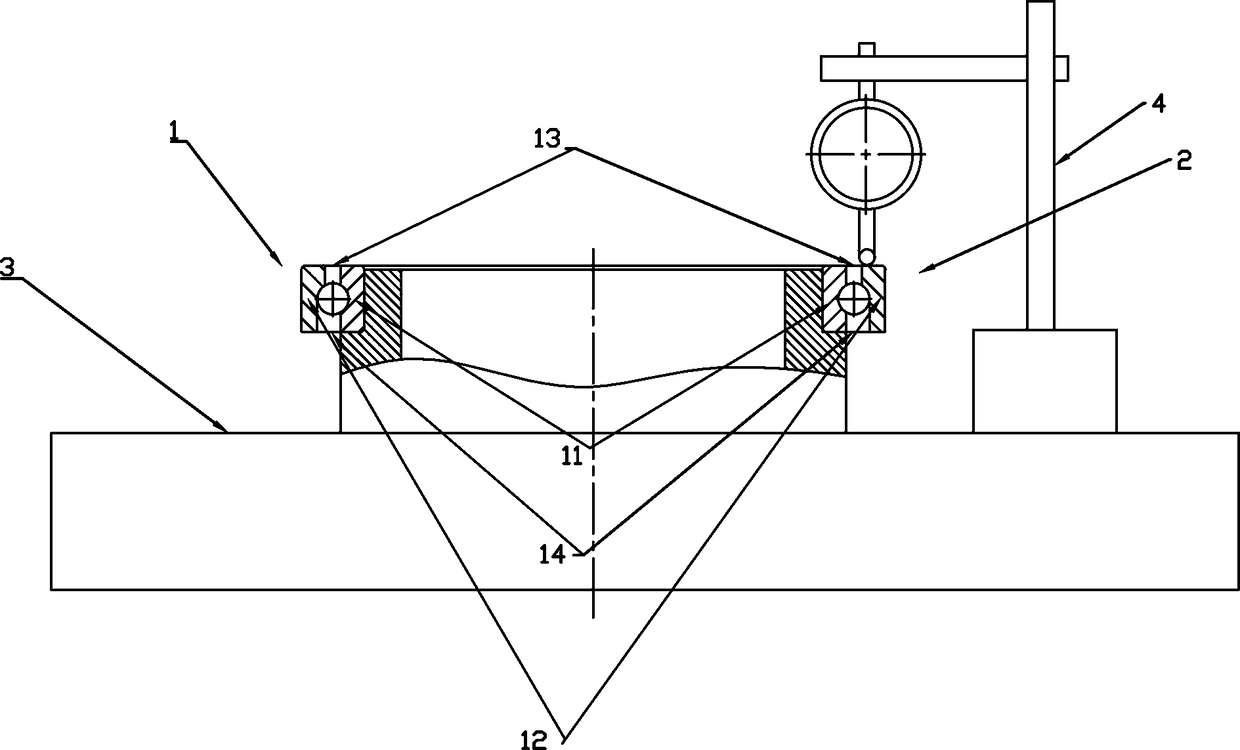

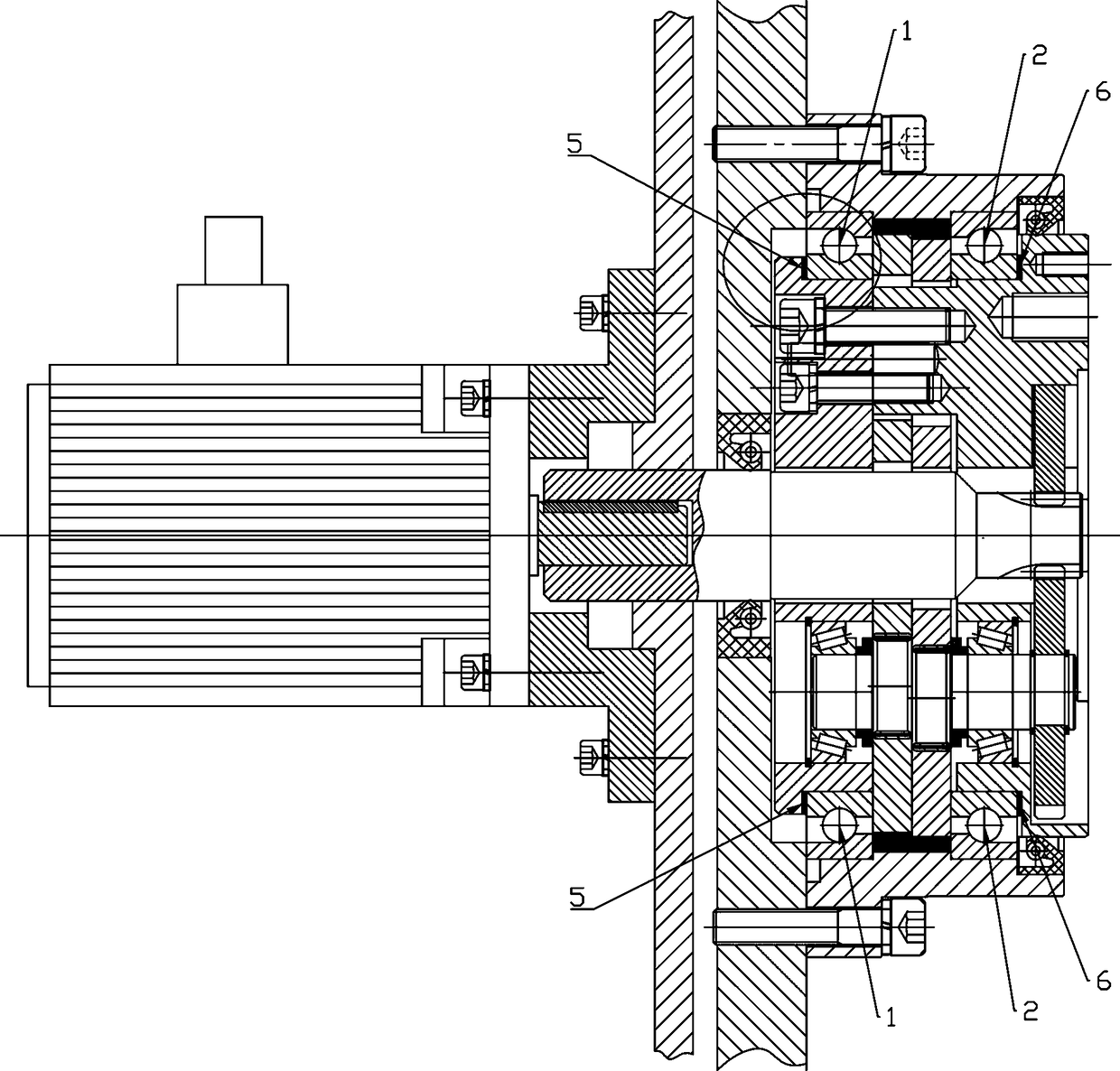

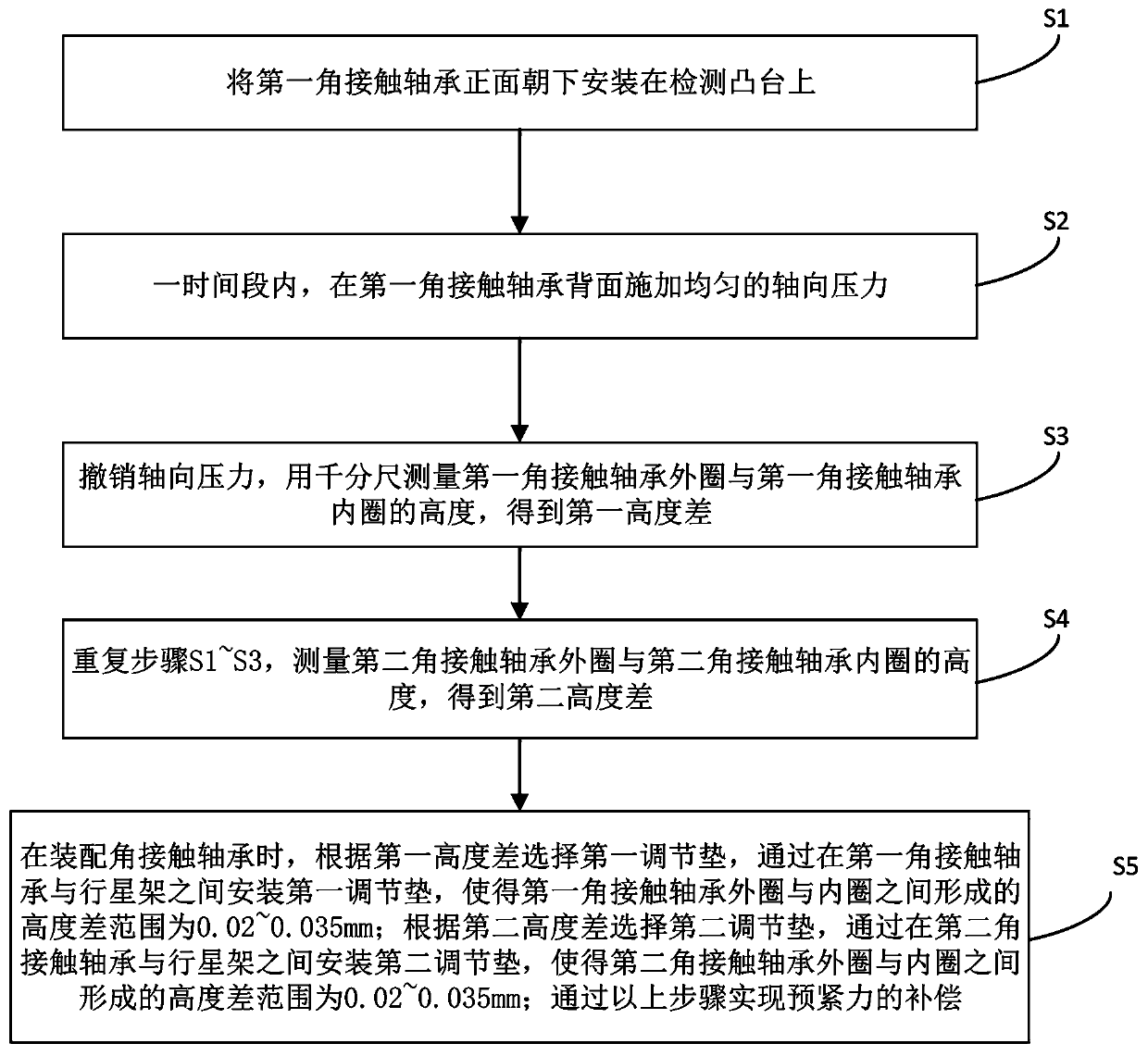

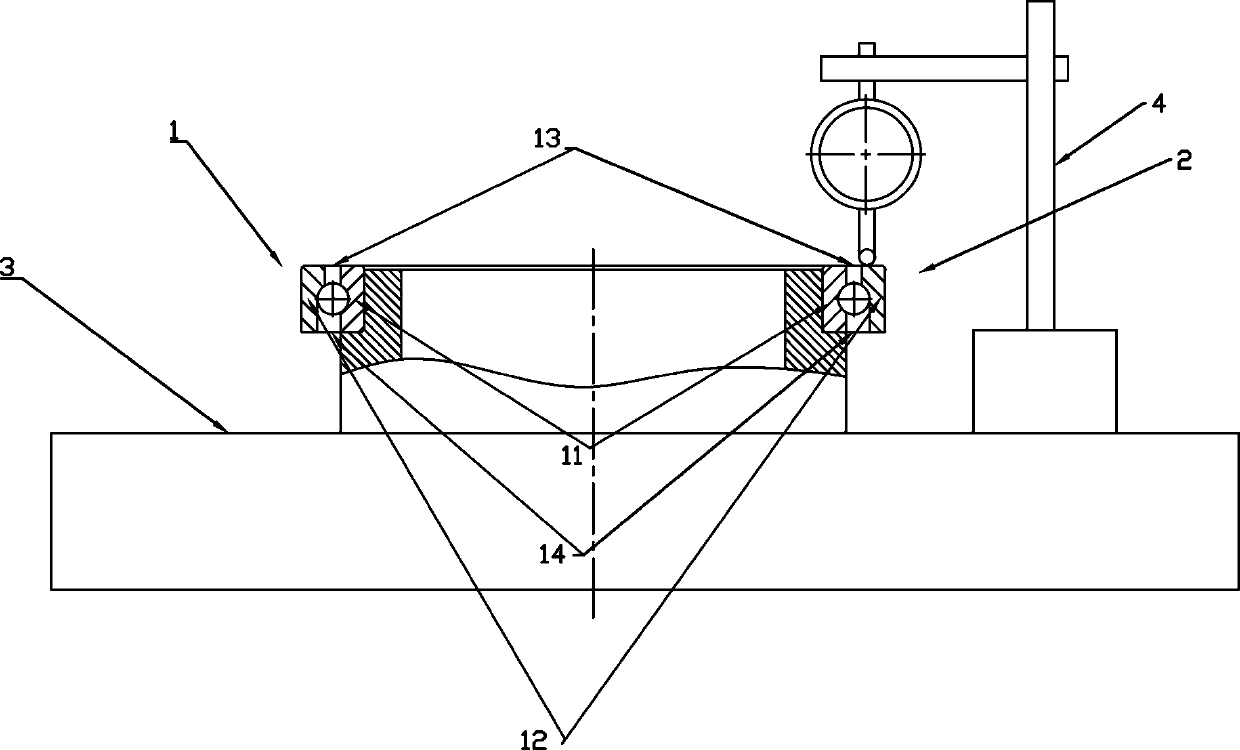

Rapid assembling method of angular contact bearing

ActiveCN108274425AExtended service lifeEasy to operateMetal-working hand toolsSpecific detectionAxial pressure

The invention provides a rapid assembling method of an angular contact bearing. According to the rapid assembling method of the angular contact bearing, angular contact bearings are installed on a specific detection boss with the back faces being upward, wherein the inner ring width is equal to the width of the step of the detection boss; then, uniform axial pressure is exerted on the back faces of the angular contact bearings; and finally, the pressure is released, the height difference between the outer ring and the inner ring of each angular contact bearing is measured through the own weight of the outer ring, during assembling, the pretightening force is adjusted through adjusting pads, after the adjusting pads are additionally arranged, the height difference between the outer ring andthe inner ring of each bearing is kept within 0.02-0.035 mm. By the adoption of the rapid assembling method, the angular contact bearings are rapidly assembled, a test device is simple and convenientto operate, especially the adjusting pads are installed between the front faces of the inner rings and a planet carrier, so that the installation precision is convenient to adjust and control; the whole detection and assembling process is short in period and easy to operate, the universality is high, and the service life of each bearing is prolonged; and the rapid assembling method of the angularcontact bearing is particularly suitable for assembling the annular contact bearings in pair between a heavy-loaded planet carrier and a shell.

Owner:湖北斯微特传动有限公司

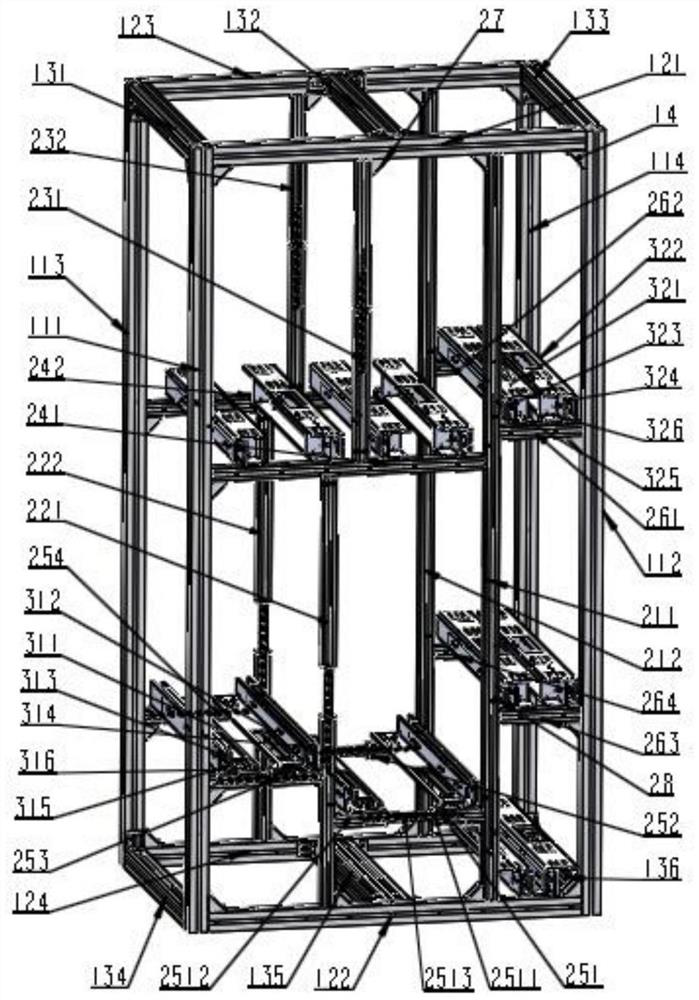

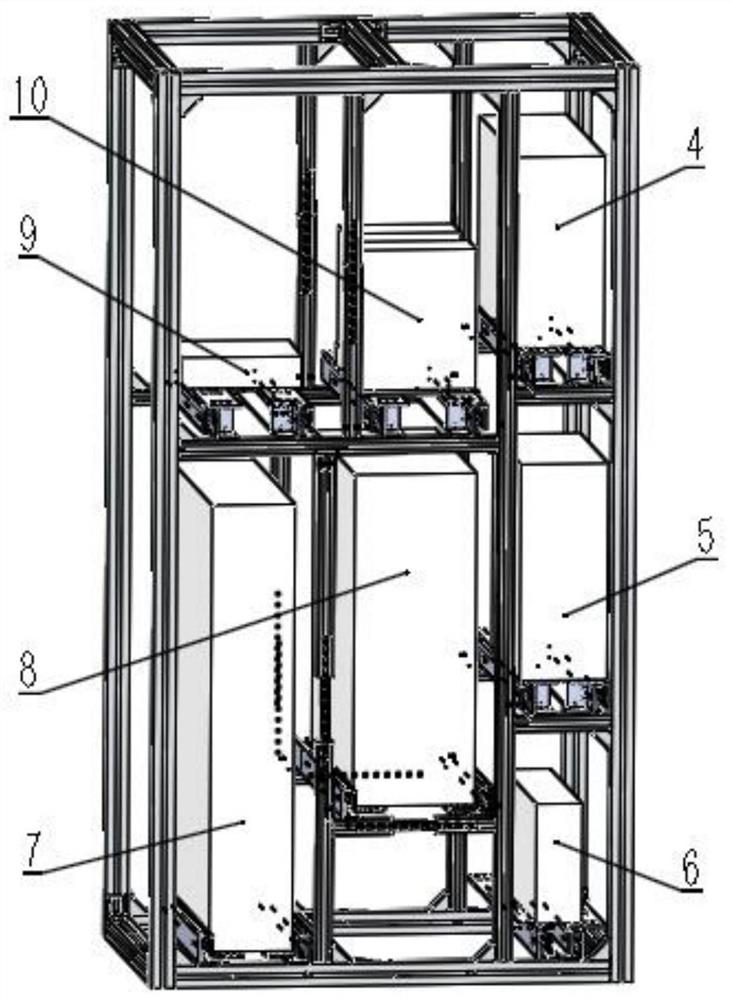

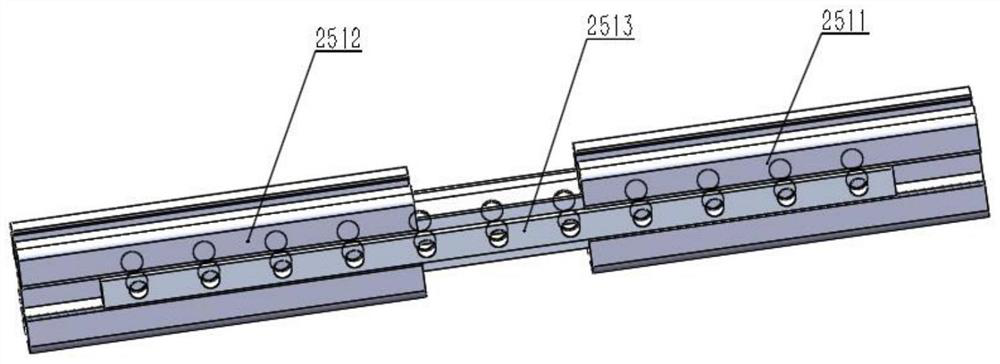

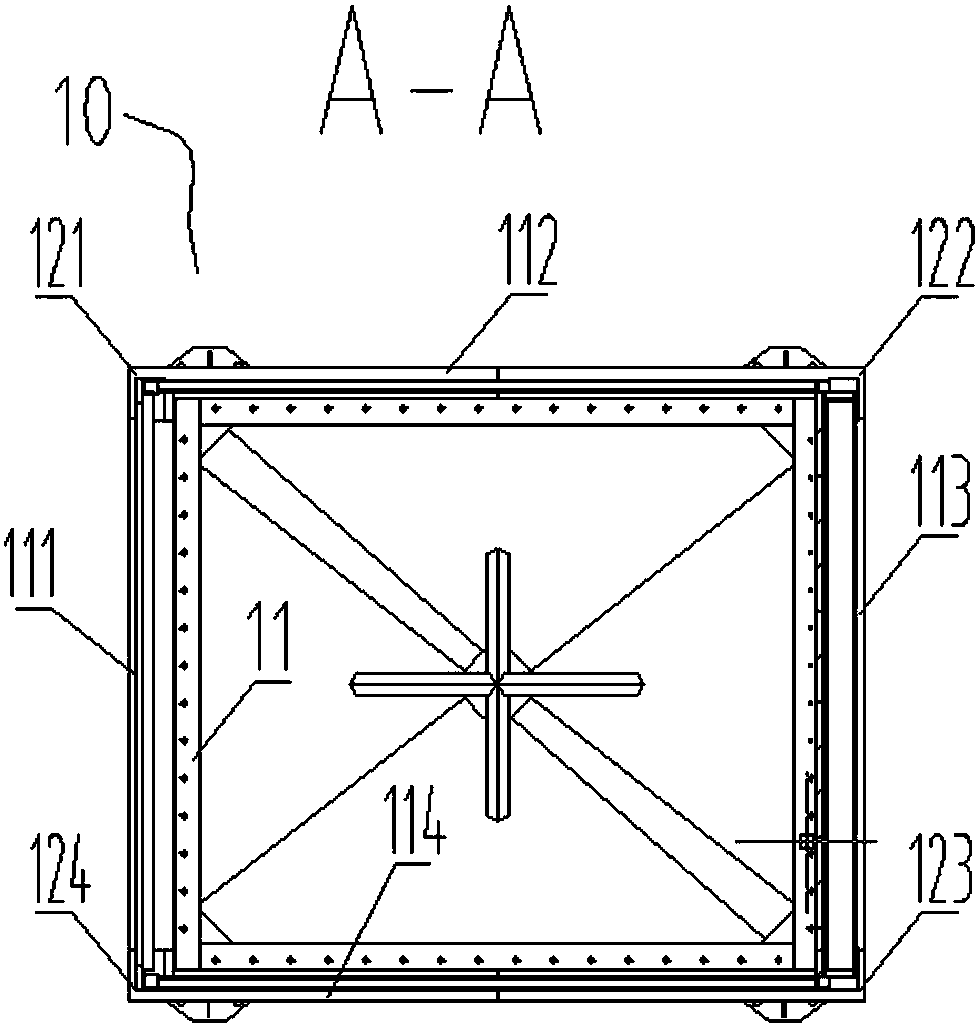

A modular automatic ticket vending machine

ActiveCN108182731BFlexible structureShorten the machine designMachines for printing and issuing ticketsInterior spaceTicket

The invention discloses a modular automatic ticketing machine case body which comprises a cubic outer frame (1), a partition frame (2) which is placed inside the outer frame (1) and divides the interior into a plurality of units, and selectable interface modules (3) on partition units. According to the outer frame (1), four outer frame columns (111, 112, 113, 114) with the same length, four outerframe cross beams (121, 122, 123, 124) with the same length, six outer frame longitudinal beams (131, 132, 133, 134, 135, 136) with the same length are fixedly connected by the same 4040 right-angle pieces (14) and T bolts to form an outer contour of the modular automatic ticketing case body with the fixed length, width and height. According to the partition frame (2), the multiple units with adjustable interior spaces are formed by the multiple columns and cross beams with different lengths. According to the modular automatic ticketing case body, the case structure can be quickly and flexiblychanged to adapt to the change of internal function modules, and the design, manufacture and assembly cycles of an automatic ticketing machine are shortened.

Owner:NANJING UNIV OF SCI & TECH

Concentric drilling tool hole-reaming sleeve component assembling tool and method

ActiveCN112371855ASimple processing technologyImprove mechanical propertiesHydraulic cylinderMachine

The invention discloses a concentric drilling tool hole-reaming sleeve component assembling tool and method. The assembling tool comprises a connecting plate, an upper pressing die and a hole-reamingsleeve positioning ring, and the connecting plate is fixedly connected with a hydraulic cylinder of a pressing machine; the upper pressing die is connected with the lower end face of the connecting plate, and a guiding conical face is arranged on the inner side face of the lower end of the upper pressing die; and the hole-reaming sleeve positioning ring is arranged on a pressing machine base located under the upper pressing die, the central axis of the upper pressing die and the central axis of the hole-reaming sleeve positioning ring coincide with the central axis of the hydraulic cylinder, and it is guaranteed that when the hydraulic cylinder of the pressing machine presses downwards, a pipe shoe is linearly pressed downwards along the central axis and arranged on the hole-reaming sleevein a sleeved mode. The concentric drilling tool hole-reaming sleeve component assembling tool is simple in structure and convenient to use, the machining process of all parts of the assembling tool is simple, the equipment investment cost is low, industrial large-scale production and use are facilitated, and assembled hole-reaming sleeve components are good in mechanical performance.

Owner:长沙百通新材料科技有限公司

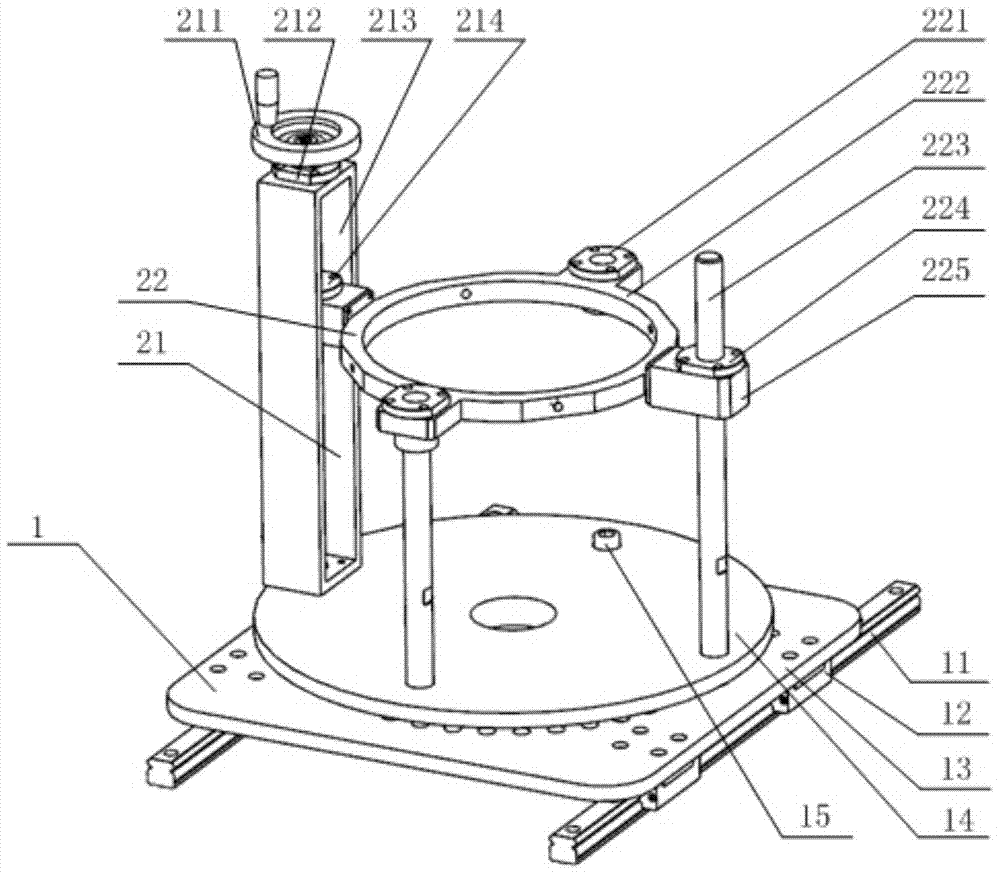

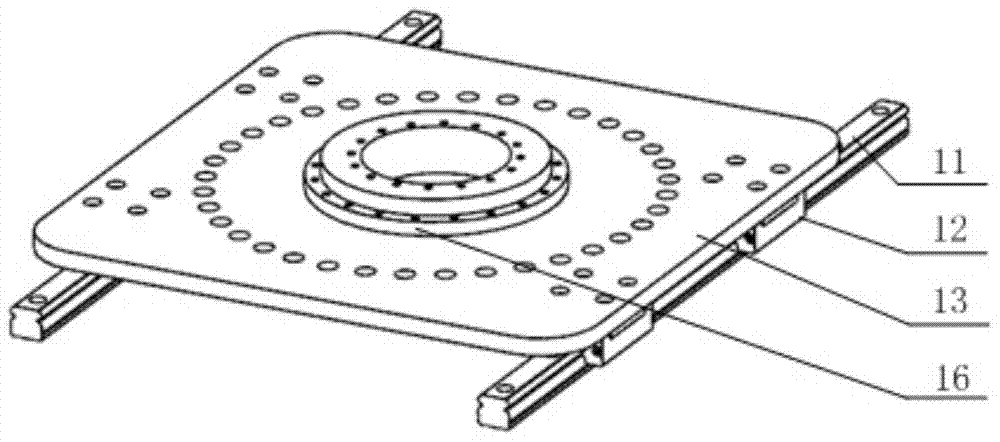

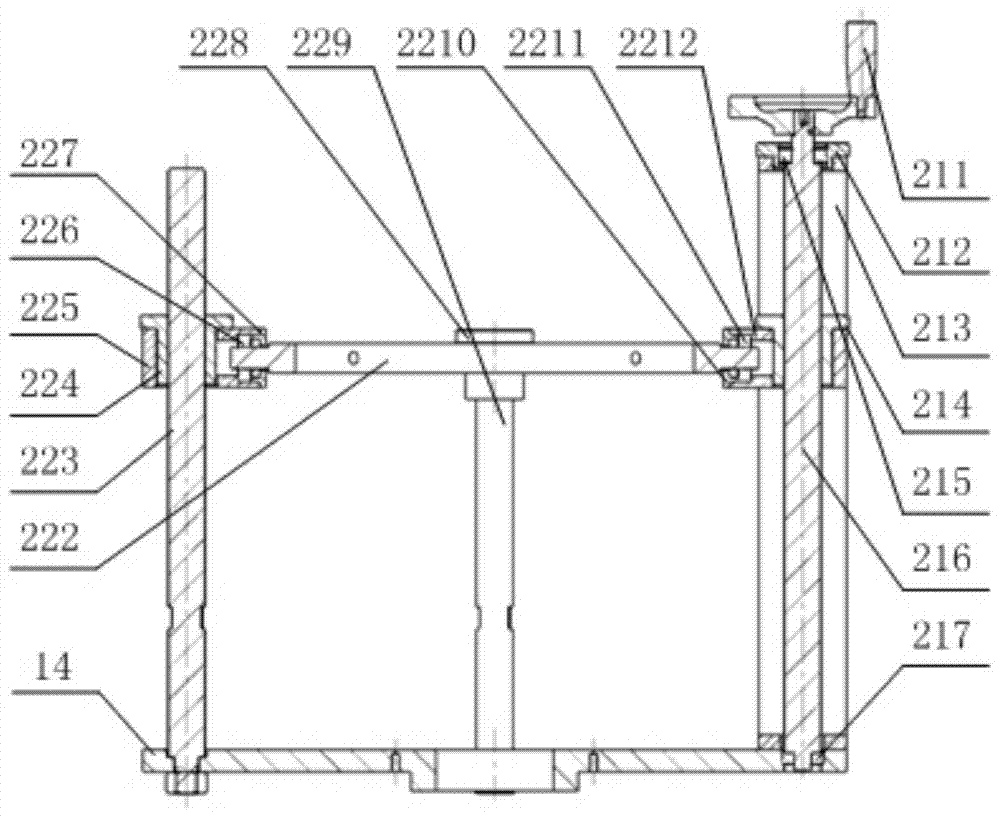

A disc-type workpiece detection station adjustment tool for coordinate measuring machines

ActiveCN105300332BGuaranteed concentricityAchieve repetitive centeringMeasurement devicesCoordinate-measuring machine

The invention discloses a disc-type workpiece detection station adjustment tool for a coordinate measuring machine. The adjustment tool includes a base (1), a lifting device (21) fixed on the base (1), and a positioning device located on the base ( 1) The overturning device (22) connected to the lifting device (21) above can realize the space overturning function of the workpiece to be detected, and has the advantages of simple structure, reasonable design, low space utilization rate, convenient installation, high efficiency and short assembly cycle Short, low cost and other advantages.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

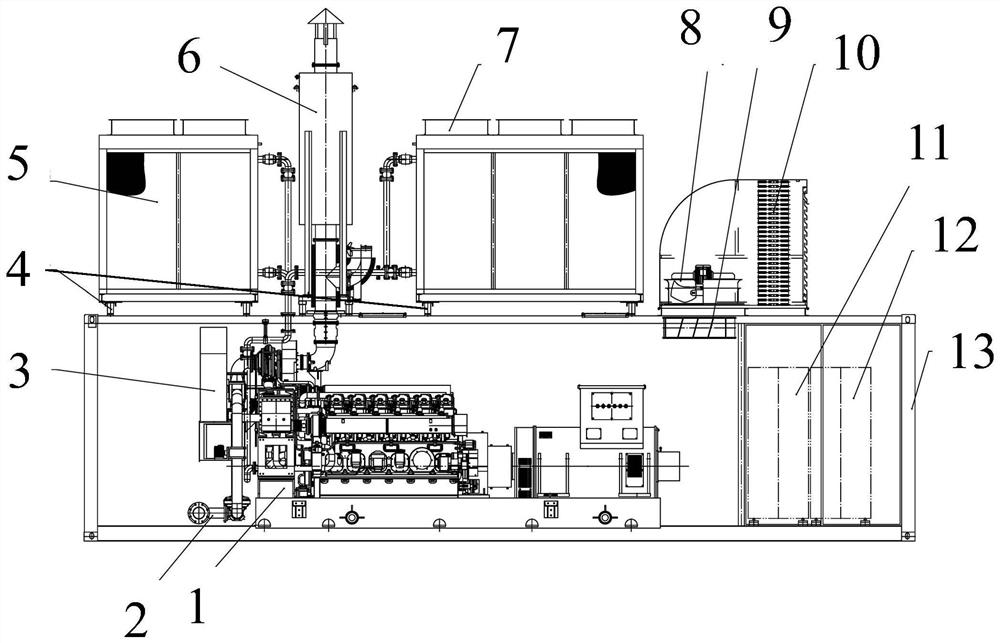

Integrated gas power generation device

InactiveCN111608798ALow costGuaranteed production cycleInternal combustion piston enginesEngine controllersPower stationMonitoring system

The invention discloses an integrated gas power generation device. The integrated gas power generation device includes a gas generator set and a movable generator house; the movable generator house includes an equipment room and a monitoring room; the equipment room is equipped with the gas generator set and a gas / air intake mechanism; the gas / air intake mechanism includes a gas intake mechanism and an air intake mechanism; the monitoring room is equipped with a main control cabinet and a circuit breaker cabinet; and the gas intake mechanism is connected to a gas source through an interface arranged on the side of the equipment room. The invention highly integrates the gas generator set, the monitoring system, the gas intake mechanism, a cooling system, an exhaust muffler system, a machineroom and the like, so as to form a micro-power station; and after the equipment is in place, power generation can be realized by connecting water, electricity, gas and the like with the outside world.

Owner:西安科美动力科技有限公司

A preparation method of graphene oxide sheet/liquid crystal/film with different number of layers

ActiveCN105174248BShort assembly cyclePhenomenon with optical birefringenceCarbon compoundsSolventCvd graphene

The invention belongs to the technical field of graphene oxide preparation, and specifically discloses a method for preparing graphene oxide sheets / liquid crystals / films with different numbers of layers. Disperse graphite oxide in a solvent, ultrasonically treat it, and then centrifuge it. Extract the lower layer of the centrifuge tube every 0.5-3 hours and mark it as a group of samples until the upper layer is colorless and transparent. Remove the solvent in the sample to obtain oxidation. Graphene sheet; the graphene oxide sheet is further centrifuged and concentrated, and the lower layer is removed to remove the solvent to obtain the graphene oxide liquid crystal; the graphene oxide liquid crystal is drop-coated on the substrate, and dried at 15-35°C to obtain the graphene oxide film . The invention solves the problem that the multi-layer, two-layer and one-layer graphene oxide sheets cannot be accurately obtained at the same time and the complicated preparation of the liquid crystal phase is solved. The graphene oxide liquid crystal of the invention is simple to prepare, has zero loss of raw materials, short film assembly cycle, and the obtained film has optical anti-counterfeiting ability, so that it has good development prospects in the field of anti-counterfeiting.

Owner:ZHENGZHOU UNIV

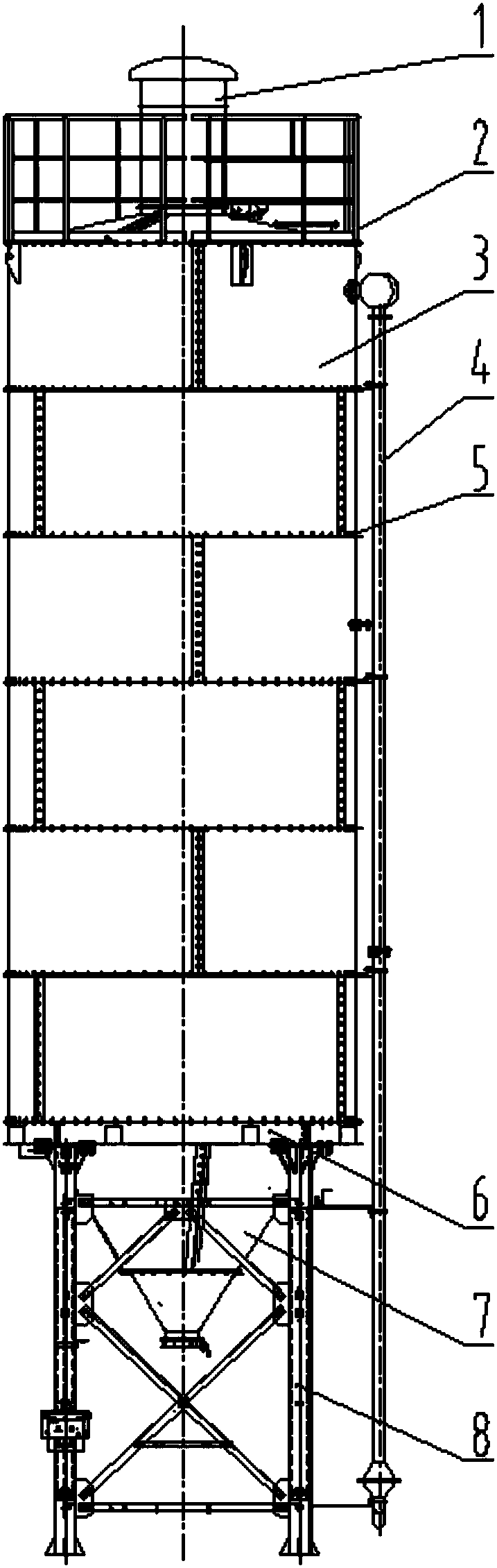

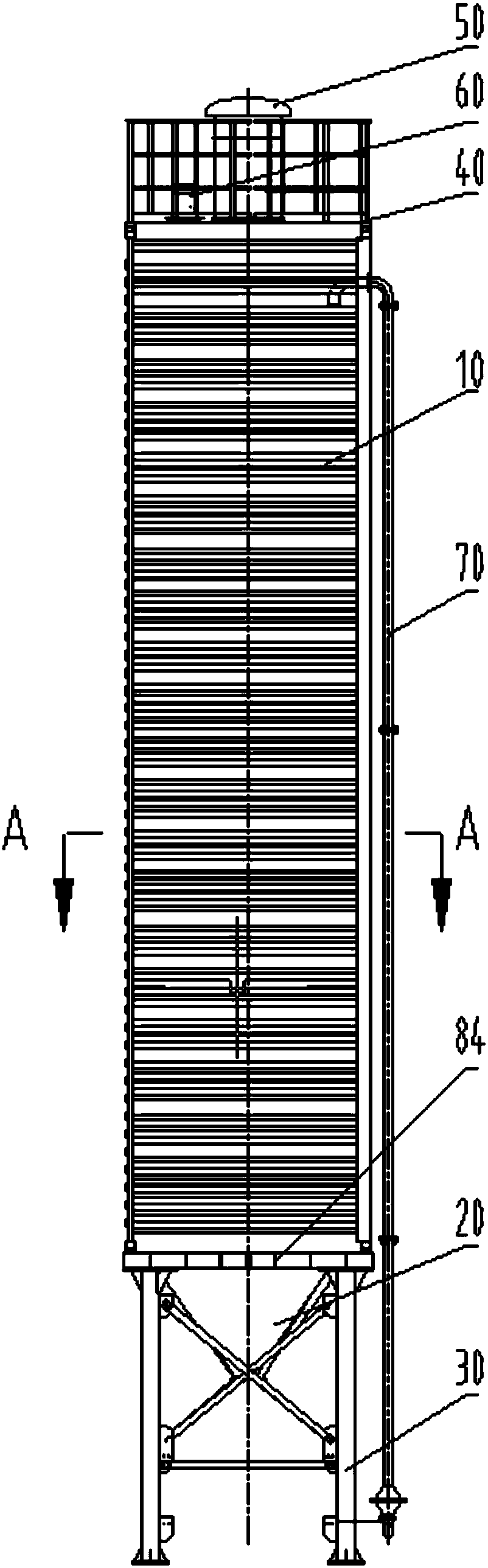

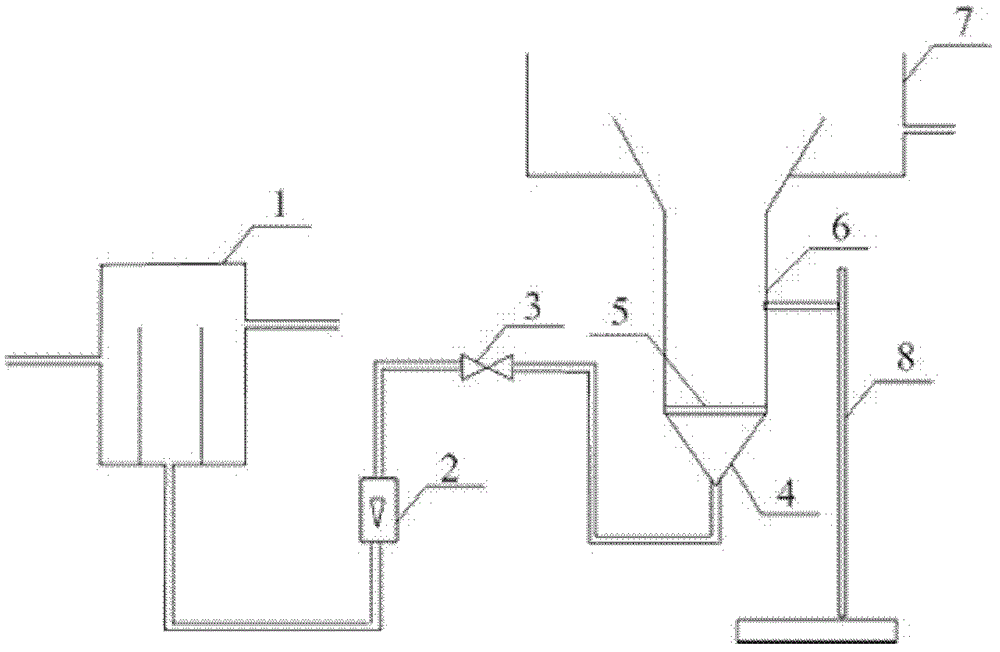

Mixing plant powder tank and mixing plant

InactiveCN108145861AReduced assembly effortReduce in quantityMixing operation control apparatusIngredients storagePetroleum engineeringSupport plane

The invention provides a mixing plant powder tank and a mixing plant. The mixing plant powder tank comprises a vertically-arranged tank body, an unloading taper arranged at the lower end of the tank body and a supporting frame used for supporting the tank body, the tank body comprises a first side plate, a second side plate, a third side plate and a fourth side plate, a box-shaped structure is defined by the first side plate, the second side plate, the third side plate and the fourth side plate, and the interior of the box-shaped structure serves as a storing space of the mixing plant powder tank. According to the scheme, as the tank body is of the box-shaped structure and can serve as a space for loading and unloading cargoes, after manufacturing in the mixing plant is completed, the unloading taper, the supporting frame and other components are placed into the tank body, in the transporting process, the tank body does not need to be loaded and transported through a container, the boxing number is greatly decreased during transporting, and the transporting cost is effectively reduced; and meanwhile, the tank body is a box, and the on-site assembling workload is small. In addition,the mixing plant powder tank can be designed according to installing topography of the mixing plant powder tank, and the storing capacity of the tank body is better improved.

Owner:SANY AUTOMOBILE MFG CO LTD

A Radar Intelligent Power Distribution System

ActiveCN105470930BRealize the control functionRealize the remote control functionEmergency protective circuit arrangementsInformation technology support systemDistribution power systemEngineering

The invention relates to a radar intelligent power distribution system, which includes a lightning protection unit, a phase sequence protection unit, an electric energy measurement unit, a three-phase power distribution unit, a single-phase power distribution unit, a state feedback unit and an output control unit. The input terminals of the protection unit, phase sequence protection unit, electric energy measurement unit, three-phase power distribution unit and single-phase power distribution unit are connected to the three-phase four-wire grid, and the lightning protection unit, phase sequence protection unit, electric energy measurement unit, three The output terminals of the phase power distribution unit and the single-phase power distribution unit are connected to the input terminals of the state feedback unit, the output terminals of the state feedback unit are connected to the input terminals of the output control unit, and the control terminals of the output control unit are respectively connected to the three-phase matching The electric unit is connected to the input end of the single-phase power distribution unit. The power distribution system described in the present invention has diversified control modes, stronger real-time monitoring, and is safe and reliable. Modular design is adopted, the functions of each unit module are clear, and the fault maintenance and replacement of components are more convenient.

Owner:ECU ELECTRONICS INDAL

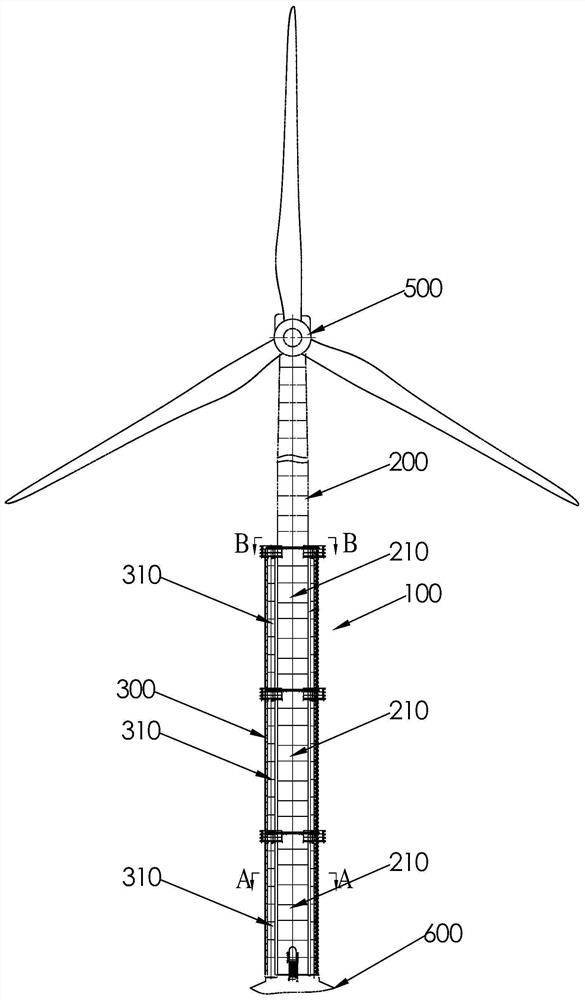

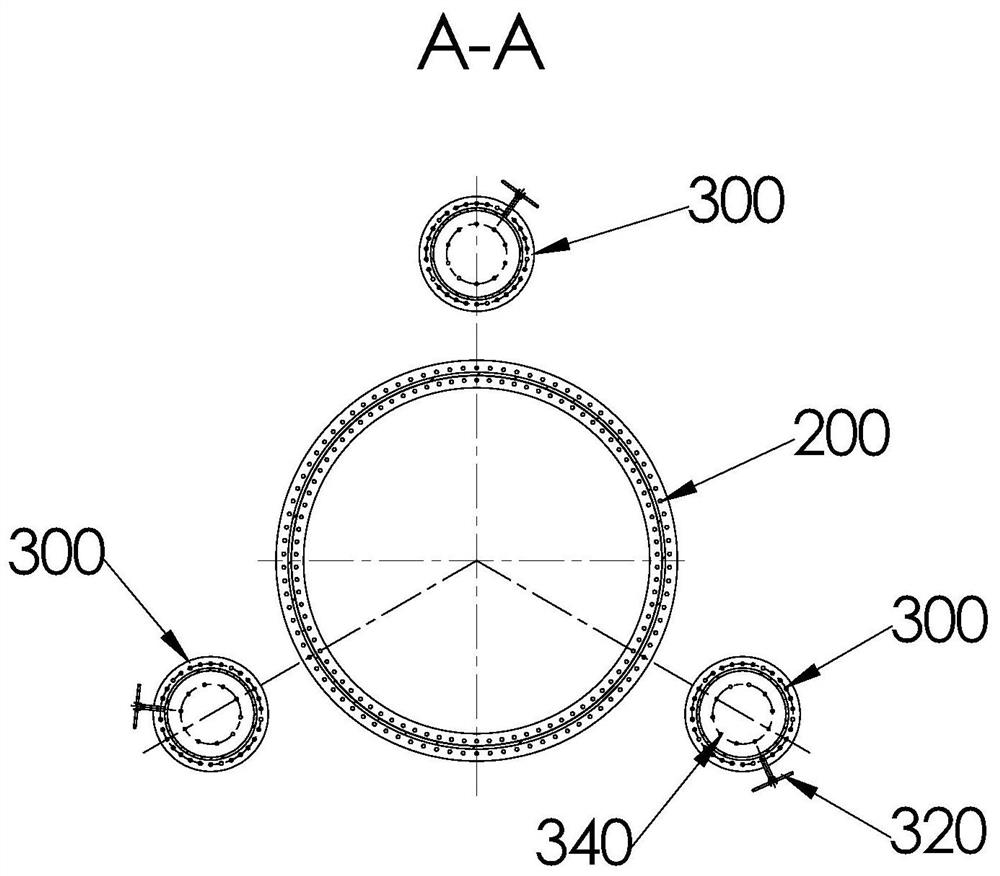

Tower and wind power generation device

PendingCN113738588AEasy to transportEasy to assembleWind motor supports/mountsMachines/enginesTowerMechanical engineering

The invention discloses a tower and a wind power generation device. The tower comprises a first stand column, a plurality of second stand columns and a plurality of connecting parts, wherein the bottom end of the first stand column is used for being connected with a tower foundation, and the top end of the first stand column is used for installing a wind generating set; the plurality of second stand columns are arranged around the first stand column, the bottom ends of the second stand columns are used for being connected with the tower foundation, and the second stand columns extend in the length direction of the first stand column; and the plurality of connecting parts are sequentially arranged in the length direction of the first stand column, and the connecting parts are correspondingly connected with the first stand column and the plurality of second stand columns. The tower is convenient to transport, easy to assemble, small in on-site assembly workload, short in assembly period and low in construction cost required by assembly.

Owner:张家口大金风电装备有限公司

Clamping type light pipe assembling and adjusting method

The invention belongs to the technical field of aviation optical equipment, and particularly relates to a clamping type light pipe assembling and adjusting method. The invention provides a clamping type light pipe assembling and adjusting method based on the shaft penetrating principle. Assembling and adjusting of a clamping type light pipe can be completed through an internal focusing light pipe,a shaft penetrating tool and wavefront testing equipment. The tool is designed, the assembling and adjusting process is reasonably arranged, only a single element is adjusted each time, operation iseasy, and the assembling and adjusting period is short.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

A method for assembling and adjusting a cassette light pipe

The invention belongs to the technical field of aviation optical equipment, and particularly relates to a method for assembling and adjusting a cassette light pipe. A cassette light pipe installation and adjustment method based on the through-axis principle is proposed. The cassette light pipe can be assembled and adjusted by using the inner focusing light pipe, through-axis tooling and wavefront testing equipment. By designing the tooling, rationally arranging the assembly and adjustment process, only a single component is adjusted each time, the operation is simple, and the assembly and adjustment cycle is short.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

An automatic assembly equipment

ActiveCN112975375BReduce human errorHigh degree of automationAssembly machinesTransfer mechanismIndustrial engineering

The invention relates to the field of automatic assembly, and discloses an automatic assembly device. The first semi-finished product is pre-assembled by the first jig on the first indexing plate, and the second semi-finished product is pre-assembled by the second jig on the second indexing plate. The mechanism transfers the first semi-finished product on the first indexing plate to the second indexing plate, and press-fits the first semi-finished product and the second semi-finished product into the third semi-finished product through the first pressing mechanism. The hook is transported to the second indexing plate, and the second pressing mechanism presses the hook and the third semi-finished product into a fourth semi-finished product, and the second transfer mechanism transfers the fourth semi-finished product on the second indexing plate to the third semi-finished product. On the indexing plate, the fourth semi-finished product on the third indexing plate is subjected to the moving test by the moving test mechanism, and the fourth semi-finished product that has passed the moving test is oiled into the finished product through the oiling module, and the whole assembly process is automated. High degree, small human error, high assembly efficiency.

Owner:昆山经坤自动化科技有限公司

Method for assembling multi-colloid photonic crystals through particle fluidization

InactiveCN102560642BSimple and fast operationShort assembly cyclePolycrystalline material growthSingle crystal growth detailsPhotonic crystalDispersed media

The invention discloses a method for assembling multi-colloid photonic crystals through particle fluidization, which includes steps of preparing dispersing solution by dispersing colloidal-state crystal particles in a dispersing medium, wherein the colloidal-state crystal particles comprise a plurality kinds of colloidal-state crystal particles with different sedimentation velocities in the dispersing medium; adding the dispersing solution into a first container, and the dispersing medium into a second container; enabling the dispersing medium in the second container to flow into the first container from the bottom of the first container; controlling the flow velocity of the dispersing medium so that one part of the crystal particles is in a fluid-bed state, and the other part of the crystal particles is in a transport-bed state; stopping the flowing of the dispersing medium into the first container when the crystal particles in the first container are divided into two layers; and leaving the first container to stand so as to obtain the multi-colloid photonic crystals through the sedimentation of the crystal particles.

Owner:BEIJING JIAOTONG UNIV

Method for assembling components of printed circuit board

InactiveCN107613667AImprove assembly efficiencyAssembly is slowPrinted circuit assemblingPrinted circuit board

The present invention relates to a method for assembling components of a printed circuit board. The method has the advantages that the assembly efficiency is improved, the time required for searchingfor the components is significantly reduced, the assembly period is short and at least a half of an assembly time is saved, phenomena of wrong assembly and missed assembly are reduced, and the reworkrate is reduced.

Owner:SHAANXI QIANSHAN AVIONICS

A Quick Assembly Method for Angular Contact Bearings

ActiveCN108274425BExtended service lifeEasy to operateMetal-working hand toolsSpecific detectionAxial pressure

The invention provides a rapid assembling method of an angular contact bearing. According to the rapid assembling method of the angular contact bearing, angular contact bearings are installed on a specific detection boss with the back faces being upward, wherein the inner ring width is equal to the width of the step of the detection boss; then, uniform axial pressure is exerted on the back faces of the angular contact bearings; and finally, the pressure is released, the height difference between the outer ring and the inner ring of each angular contact bearing is measured through the own weight of the outer ring, during assembling, the pretightening force is adjusted through adjusting pads, after the adjusting pads are additionally arranged, the height difference between the outer ring andthe inner ring of each bearing is kept within 0.02-0.035 mm. By the adoption of the rapid assembling method, the angular contact bearings are rapidly assembled, a test device is simple and convenientto operate, especially the adjusting pads are installed between the front faces of the inner rings and a planet carrier, so that the installation precision is convenient to adjust and control; the whole detection and assembling process is short in period and easy to operate, the universality is high, and the service life of each bearing is prolonged; and the rapid assembling method of the angularcontact bearing is particularly suitable for assembling the annular contact bearings in pair between a heavy-loaded planet carrier and a shell.

Owner:湖北斯微特传动有限公司

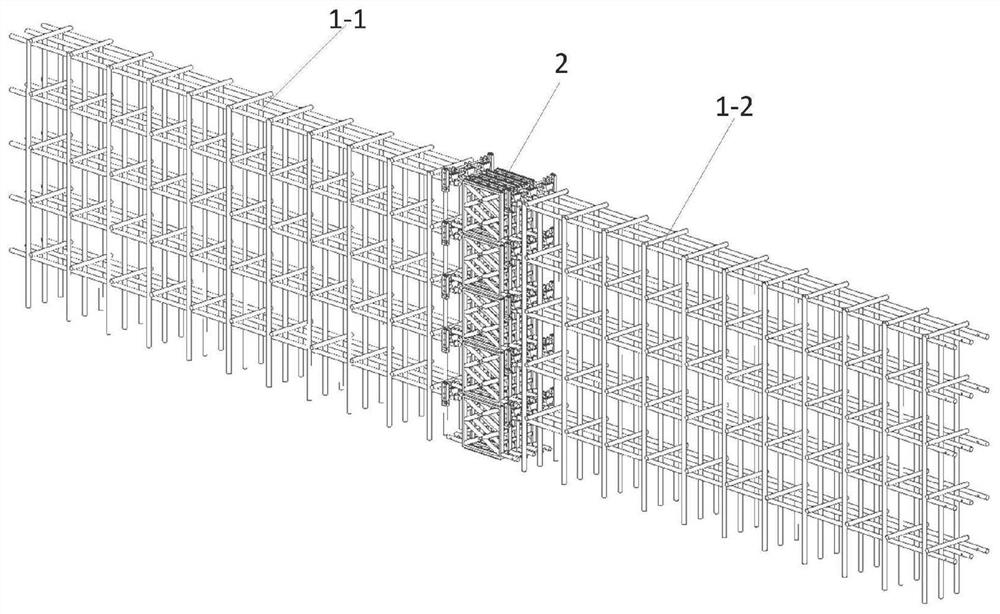

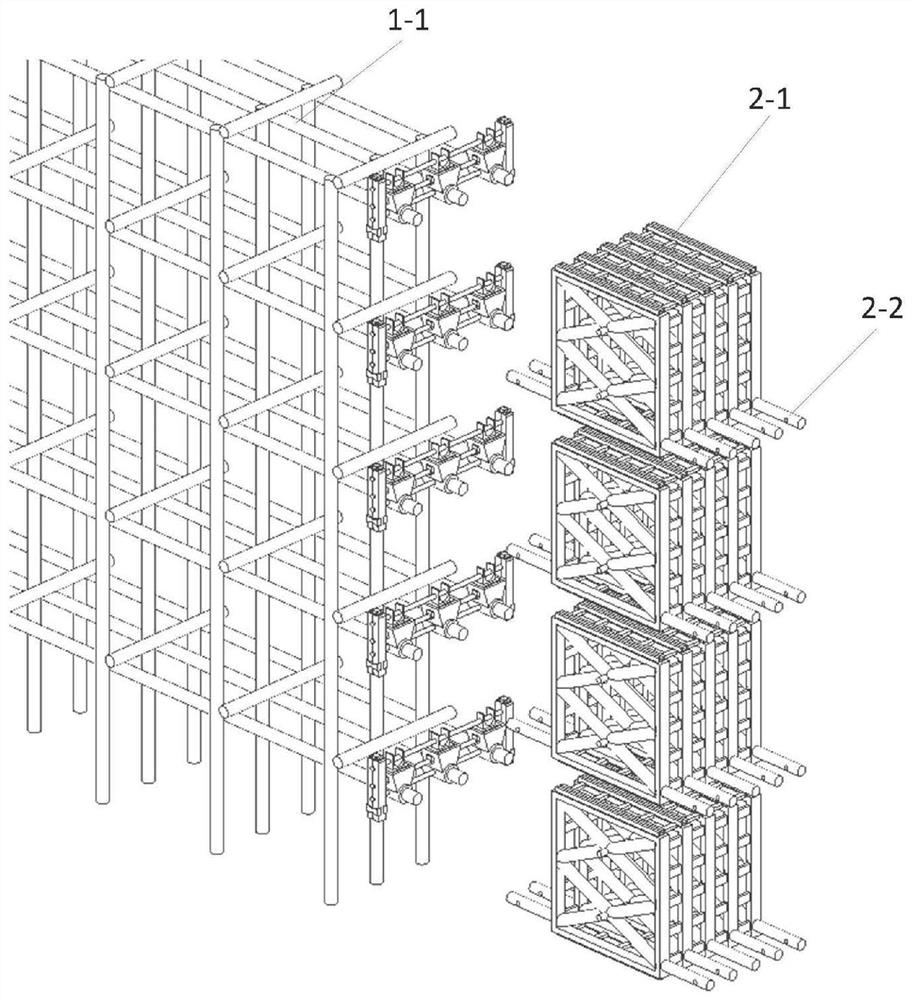

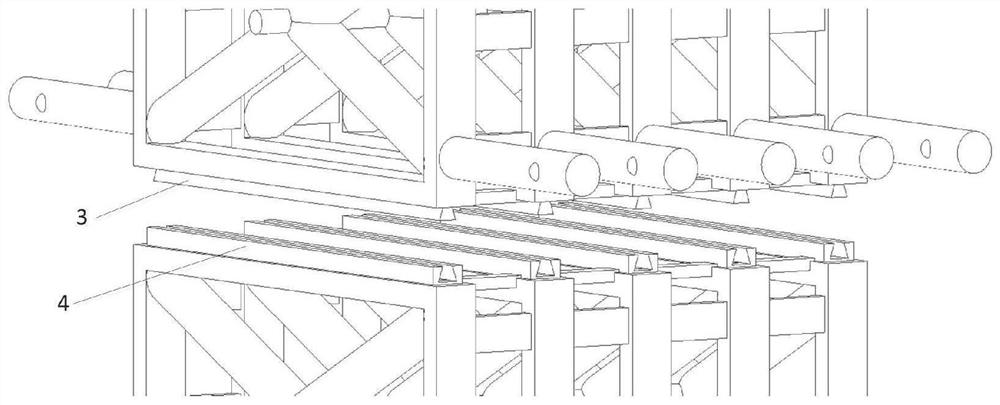

Underground diaphragm wall tenon-and-mortise type reinforcement cage connecting structure

ActiveCN113235569AImprove job qualityImprove work efficiencyArtificial islandsUnderwater structuresArchitectural engineeringRebar

The invention discloses an underground diaphragm wall tenon-and-mortise type reinforcement cage connecting structure which comprises underground diaphragm walls, a tenon-and-mortise type connecting frame, a dovetail groove, a dovetail joint, a coupler female head, a coupler male head, penetrating steel shafts and a shaft clamping device clamp. The two underground diaphragm walls are connected through the tenon-and-mortise type connecting frame, concrete is poured on the tenon-and-mortise type connecting frame in a layered mode, and the underground diaphragm walls and the tenon-and-mortise type connecting frame are connected into a whole. Main bodies of reinforcing steel bars reserved at the wall body are fixed by a reinforcement cage in a plug-in manner, and multiple groups of parallel penetrating steel shafts are used for fastening, so that the quality unevenness caused by welding and fixing and the complicated process of quality inspection and checking are reduced; and the technical requirements of green construction, civilized construction and fabricated construction are met. The assembly type structure is simple in process, the assembly period is short, and a large amount of manpower and time expenditure on site are saved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com