Assembled adjustable steel bar binding clamping fixture support

A steel bar binding and assembly technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems that affect the construction progress and construction quality, increase the complexity of the site, increase the mechanical equipment and other problems, and achieve short assembly cycle and adjustable performance Good, the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

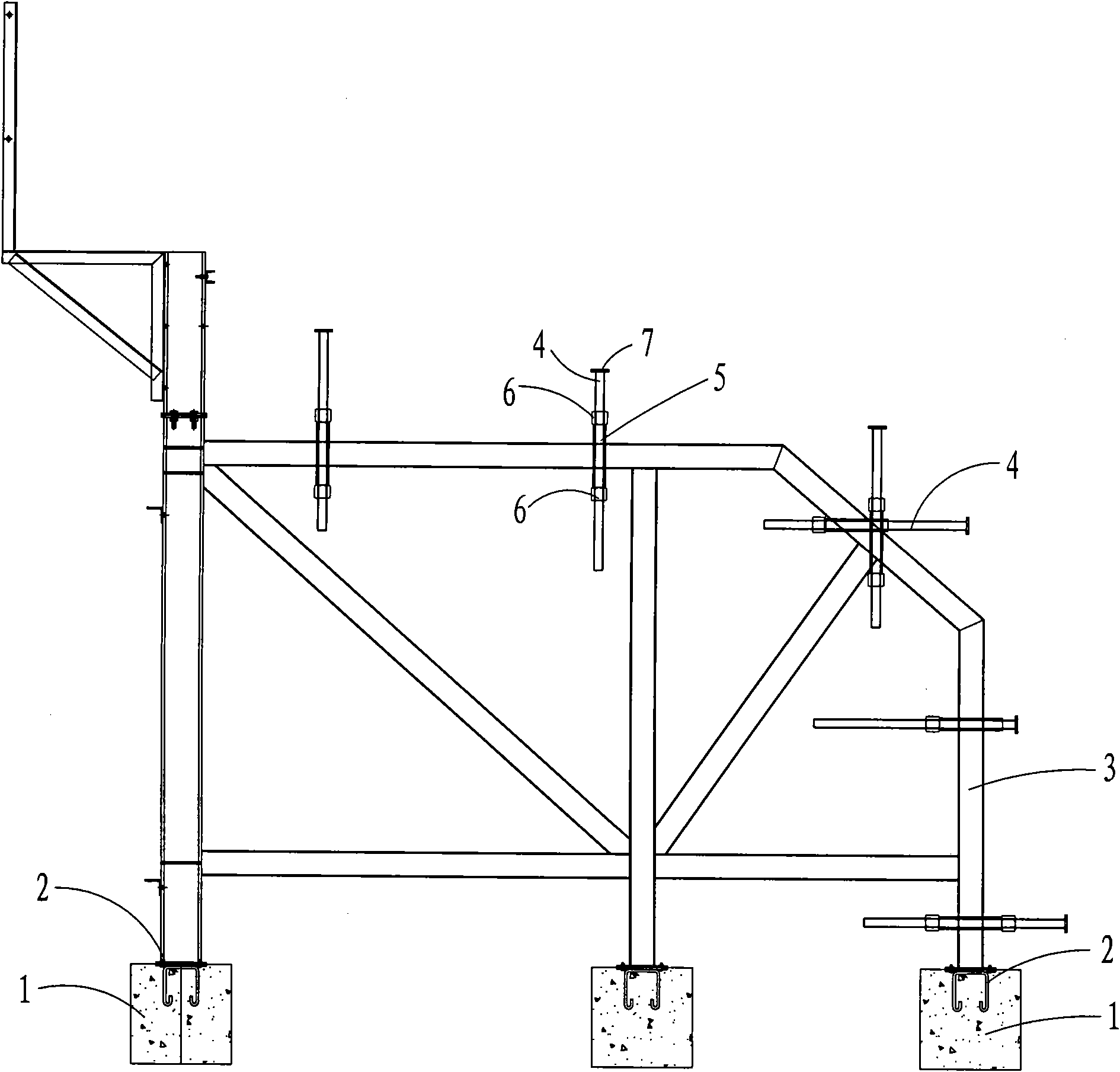

[0026] see figure 1 , the assembly-type adjustable steel bar binding tire bracket in this embodiment is based on the steel plate assembly 2 embedded in the bottom pier 1; on the steel plate assembly 2, it is fixed and supported by bolts according to the shape of the steel bar of the beam body Frame 3; on the support frame 3, each support rod 4 is arranged at intervals, the support height of the support rod 4 on the support frame 3 can be adjusted, and the support end of the support rod 4 is provided with an end plate 7 for fixing the limit angle steel.

[0027] In specific implementation, the support rod 4 is set as a screw rod, and the support frame 3 at the corresponding position is provided with a sleeve 5, and the support rod 4 is inserted in the sleeve 5, and on the support rod 4, is located at both ends of the sleeve 5. There are positioning nuts 6 for adjusting and fixing the support height of the support rod 4 on the support frame 3; the support frame 3 and the steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com