Method for assembling multi-colloid photonic crystals through particle fluidization

A technology of colloidal photonic crystals and particle flow, applied in chemical instruments and methods, crystal growth, polycrystalline material growth, etc., can solve the problems of long assembly cycle, low efficiency, and complicated operation, and achieve short assembly cycle, high efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

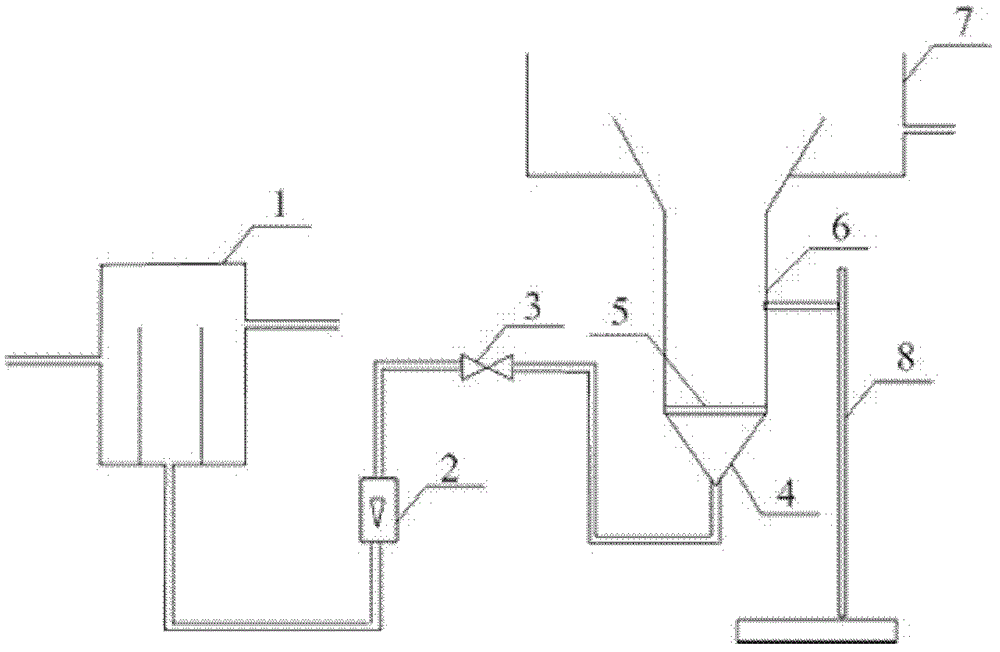

[0028] Such as figure 1 As shown, the device used in the method for particle fluidization assembly of multi-component colloidal photonic crystals provided in this embodiment includes a constant interface liquid storage tank 1, a flow meter 2, a valve 3, a slow flow device 4, a distribution plate 5, a fluidized bed reaction Device 6, sump 7 and fixing device 8. The constant interface liquid storage tank 1 is sequentially connected with the flow meter 2, the valve 3 and the slow flow device 4 through pipelines; the distribution plate 5 is installed at the bottom of the fluidized bed reactor 6; The slow flow device 4 is installed under the distribution plate 5; the liquid collection tank 7 is installed on the top of the fluidized bed reactor 6. The distribution plate 5 has a plurality of small holes for uniformly dispersing the dispersion medium passed into the fluidized bed reactor 6 . The damper 4 is used to buffer the dispersion medium. The fixing device 8 is used to fix th...

Embodiment 2

[0057] The device used in the method for particle fluidization assembly of multi-component colloidal photonic crystals provided in this example is exactly the same as that used in Example 1.

[0058] The particle fluidized assembly PMMA / Fe that this embodiment provides 3 o 4 The method for composite multi-element colloidal photonic crystal comprises the following steps:

[0059] For example, two colloidal PMMA / Fe with the same particle size and different densities 3 o 4 The composite material crystal particles are dispersed in the dispersion medium, and the preparation containing PMMA / Fe 3 o 4 A dispersion of crystal particles, wherein the two PMMA / Fe 3 o 4 The total mass percent concentration of crystal particles is, for example, 1.0%; the two PMMA / Fe 3 o 4 The density of the crystal particles is eg 2000kg / m respectively 3 and 4000kg / m 3 , its shape is for example all spherical; Dispersion medium adopts such as distilled water; Use mechanical stirring or ultrasonic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com