A preparation method of graphene oxide sheet/liquid crystal/film with different number of layers

A technology of graphene film and graphene sheet, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems that the self-assembly process of graphene oxide sheet has not been reported, and achieve good application prospects, simple method, The effect of controllable film size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

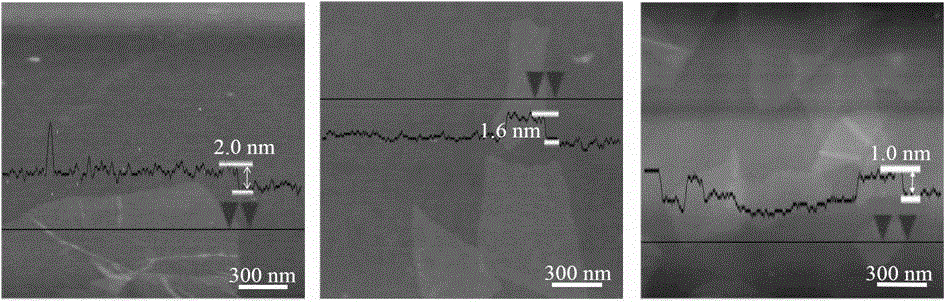

[0018] (1) Disperse 2g of graphite oxide in 1600ml of deionized water to form a suspension with a mass concentration of 0.125%, ultrasonicate for 0.5h at a power of 240W to disperse the graphite oxide in deionized water evenly; put the dispersion at 10000 r / min Centrifuge at a constant centrifugation rate, extract the bottom layer of the centrifuge tube every 30 minutes and record it as a group of samples, and extract 12 times in total. The atomic force microscope photos of the samples extracted at intervals of 30 minutes, 3 hours and 6 hours are shown in figure 1 , it can be seen that the samples extracted at intervals of 30min, 3h, and 6h are respectively multi-layer, double-layer, and single-layer graphene oxide sheets, that is, as the extraction time increases, the thickness of the sample (the number of layers) gradually decreases;

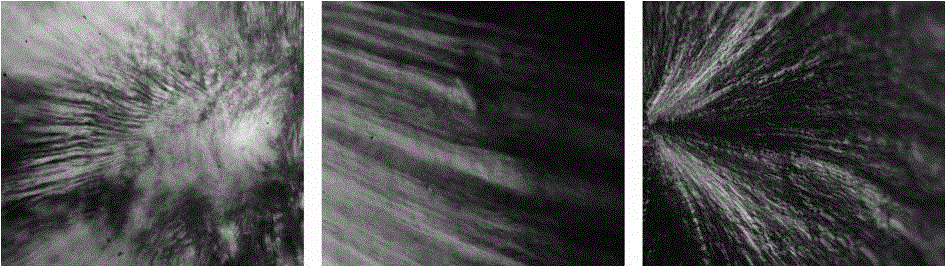

[0019] (2) Then centrifuge and concentrate the samples extracted at intervals of 30min, 3h, and 6h at 10,000 r / min for 30min, and the lower la...

Embodiment 2

[0022] Extend the interval time in step (1) to 2h, and extract 4 times. Correspondingly, the centrifugation time in step (2) is also extended to 2h, and the others are the same as in Example 1.

Embodiment 3

[0024] (1) Disperse 1g of graphite oxide in 1500ml of deionized water to form a suspension with a mass concentration of 0.067%, ultrasonicate for 20min at a power of 240W to disperse graphite oxide in deionized water evenly; keep the dispersion at 10000 r / min constant Centrifuge at a centrifugal speed, extract the bottom layer of the centrifuge tube every 1 hour, record it as a set of samples, extract 6 times in total, and obtain graphene oxide sheets with gradually reduced layers;

[0025] (2), and then centrifuge and concentrate the above samples at 10,000 r / min for 1 hour, and the lower layer is graphene oxide liquid crystal;

[0026] (3) Then, drop-coat the obtained graphene oxide liquid crystal on a glass plate, and dry it naturally at room temperature of 25° C. to obtain a graphene oxide film with birefringence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com