Concentric drilling tool hole-reaming sleeve component assembling tool and method

A technology for assembling tooling and assembling method, which is applied in the field of concentric drilling tool reaming sleeve assembly assembly tooling and its assembly, can solve the problems of inconvenient operation, easy occurrence of safety accidents, low precision of clearance control of reaming sleeve assemblies, etc. Long service life, convenient for industrial-scale production and use, and the effect of reducing equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

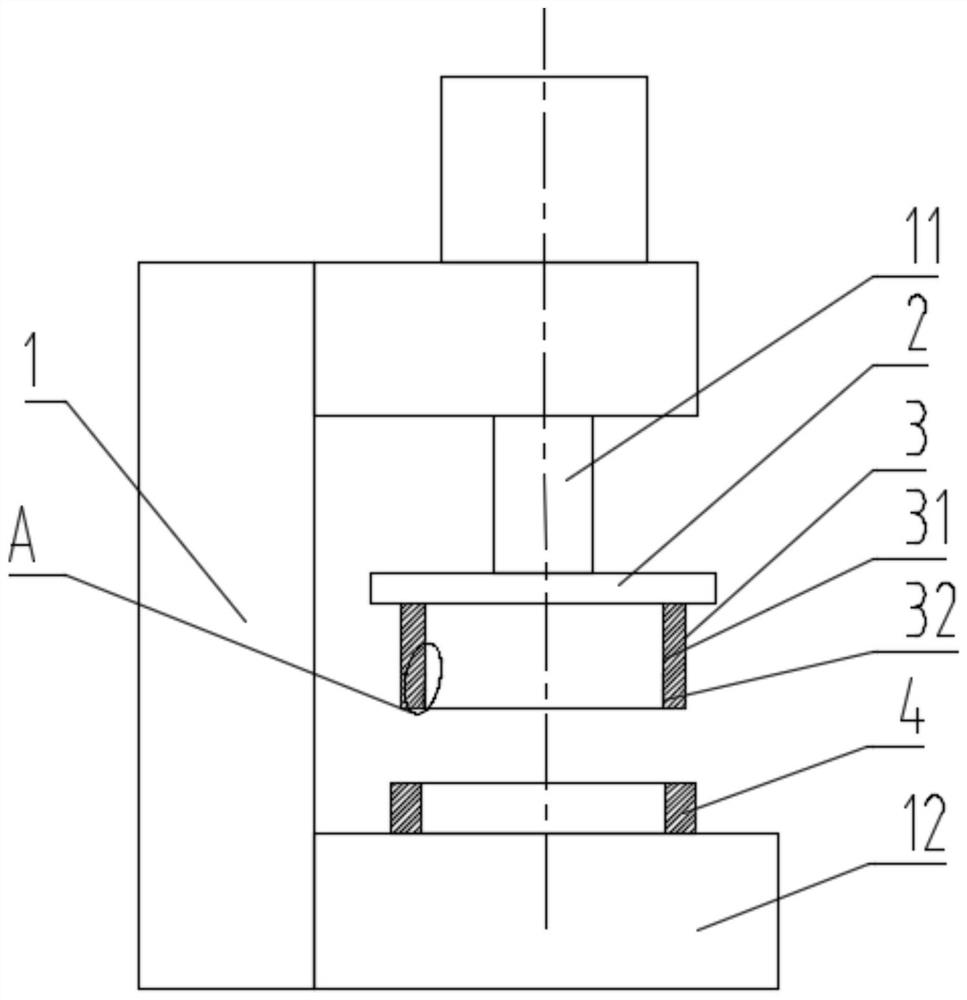

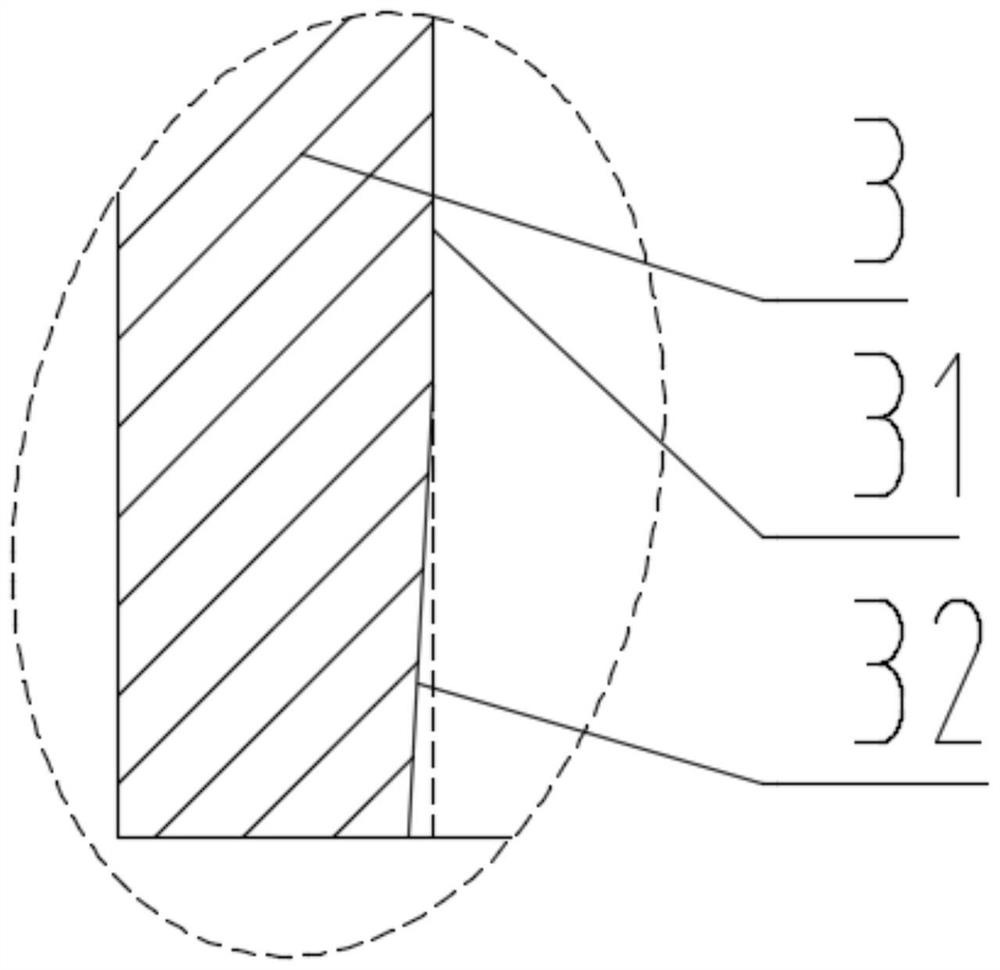

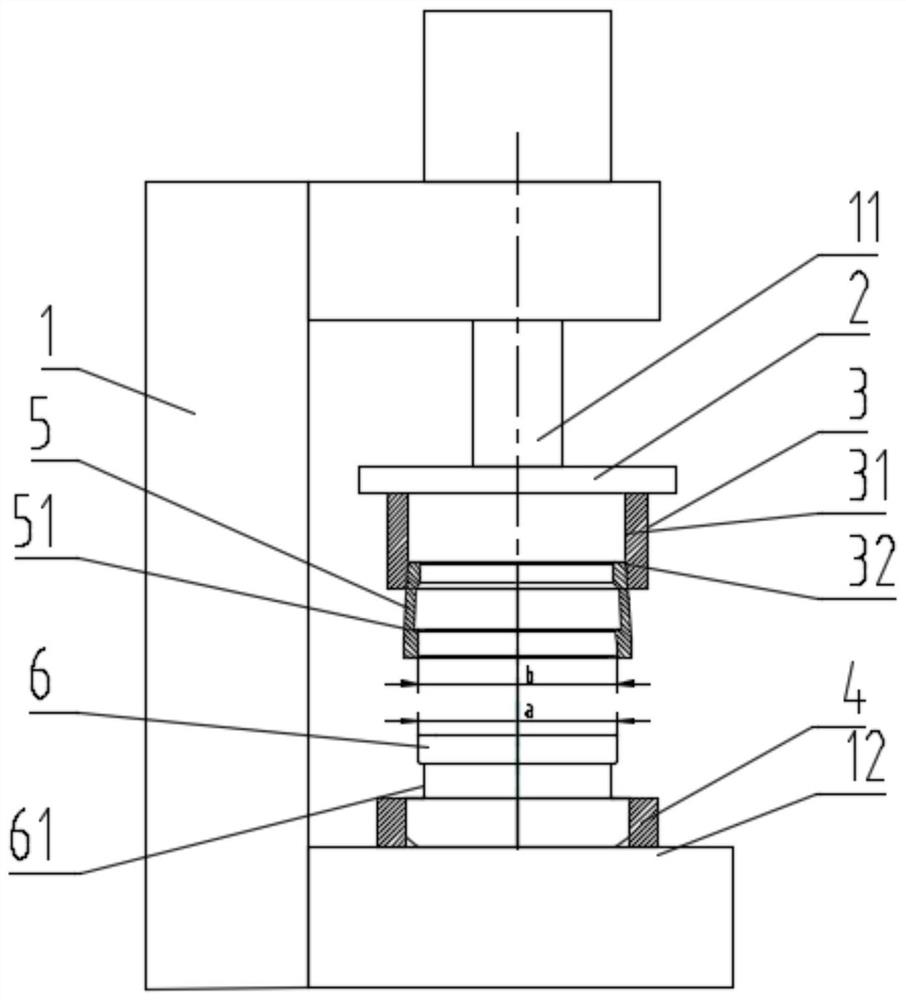

[0035] refer to Figure 1~4 , a concentric drilling tool reaming sleeve 6 component assembly tooling, including a connecting plate 2, an upper pressing die 3 and a reaming sleeve positioning ring 4, the connecting plate 2 is fixedly connected with the hydraulic cylinder 11 of the press 1; the upper The pressing die 3 is connected to the lower end surface of the connecting plate 2, and the inner surface of the lower end of the upper pressing die 3 is provided with a guiding tapered surface 32; , and the central axis of the upper pressing die 3 and the positioning ring 4 of the reaming sleeve coincides with the central axis of the hydraulic cylinder 11 to ensure that when the hydraulic cylinder 11 of the press 1 is pressed down, the pipe shoe 5 is pressed straight down along the central axis and set on the On the reaming sleeve 6.

[0036] The taper of the guide tapered surface 32 matches the tapered surface of the top outer surface of the pipe shoe 5 .

[0037] The length of ...

Embodiment 2

[0043] A concentric drilling tool reaming sleeve 6 component assembly method, using the concentric drilling tool reaming sleeve 6 component assembly tooling described in the above embodiment 1, the assembling method includes the following steps:

[0044] 1) Prepare assembly tooling: Align the center of the upper pressing die 3 and the center of the reaming sleeve positioning ring 4 with the hydraulic cylinder 11, and put the reaming sleeve 6 into the reaming sleeve positioning ring 4, so that the upper pressing die 3 and the expanding sleeve The central axis of the hole sleeve positioning ring 4 and the reaming sleeve 6 coincides with the central axis of the hydraulic cylinder 11, and then spray a release agent on the inner hole wall of the upper pressing mold 3;

[0045] 2) Heat treatment of the pipe shoe 5: place the pipe shoe 5 in a heating furnace and heat at 900°C for 20 minutes, so that the inner diameter (a) of the bottom of the pipe shoe 5 is 2mm larger than the outer d...

Embodiment 3

[0050] refer to Figure 5 , a concentric drilling tool reaming sleeve 6 component assembly tooling of this embodiment, compared with Embodiment 1, there are the following differences:

[0051] The inner surface of the bottom of the reaming sleeve locating ring 4 is provided with a ramp 41 that matches the conical surface at the bottom of the reaming sleeve 6. The contact area at the bottom of 6 is larger, and the force on the bottom of the reaming sleeve 6 is more uniform.

[0052] It should be noted that, in the assembly tooling of a concentric drilling tool reaming sleeve 6 assembly of the present invention, the length of the guide tapered surface 32 can also be 12mm, 18mm or 20mm, and the straight cylindrical surface of the upper pressing die 3 The height of 31 is 8mm or 12mm greater than the height of the pipe shoe 5; the changes of the above technical features can be understood and implemented by those skilled in the art through the text description, so no additional dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com