Direct drive type numerical control precision rotary table and machine tool

A direct-drive, precise technology, used in drive devices, metal processing mechanical parts, large fixed members, etc., can solve problems such as low transmission efficiency, complex assembly, increased backlash of gear pairs or worm gear pairs, etc. High positioning accuracy and repeat positioning accuracy, convenient installation and debugging, and short assembly cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

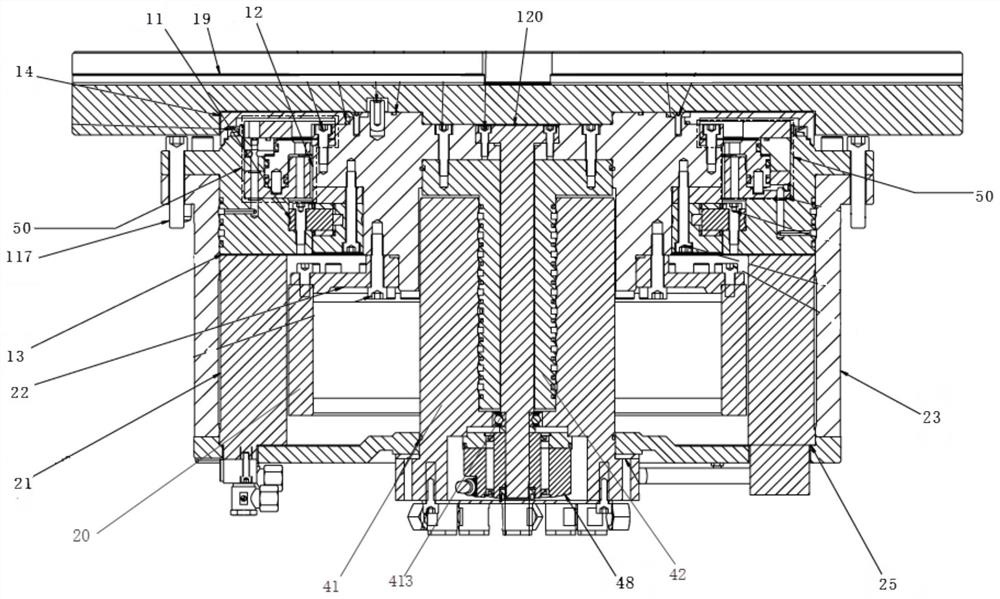

[0039] This embodiment provides a direct-drive CNC precision turntable, such as figure 1 As shown, it includes a turntable bearing 11, a rotary spindle 12, a turntable bearing seat 13, a rotor 20 of a torque motor, a stator 21 of a torque motor, a connecting flange 22, a rotary table 19, a connecting flange chassis 25 and a bushing 23 ;

[0040] The rotor 20 of the torque motor is rigidly connected to the rotary spindle 12 by connecting the flange 22 and fastening bolts; the inner ring of the turntable bearing 11 is assembled and connected to the rotary spindle 12, and the rotary table 19 is directly rigidly connected to the rotary spindle 12 .

[0041] The stator 21 of the torque motor is assembled and connected with the connecting flange chassis 25 and the bushing 23 through fastening bolts; the outer ring of the turntable bearing 11 is assembled and connected on the turntable bearing seat 13, and then the turntable bearing seat 13 is connected with the fixed torque motor s...

Embodiment 2

[0048] This embodiment provides a machine tool, including the direct-drive CNC precision turntable described in any one of the first embodiment.

[0049] To sum up, the present invention provides a direct-drive CNC precision turntable and machine tool. The rotary table is directly driven by a torque motor without any transmission pair in the middle to achieve "zero" backlash, and theoretically there is no mechanical transmission chain wear and no loss of transmission efficiency; because the torque motor has extremely high static and dynamic load rigidity, it can maintain high positioning accuracy and repeat positioning accuracy even under high-speed rotary motion; the torque motor directly drives the rotary table, which can provide higher With large torque, it participates in the turning process and realizes the combined function of turning and milling; the design adopts a hydraulic brake device to realize the powerful cutting process after the rotary table is braked and locked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com