Rapid assembling method of angular contact bearing

An angular contact bearing and assembly method technology, applied in the field of bearing assembly, can solve the problems of long assembly cycle and difficult debugging of angular contact bearing pre-tightening force, and achieve the effects of convenient operation, easy operation, easy adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

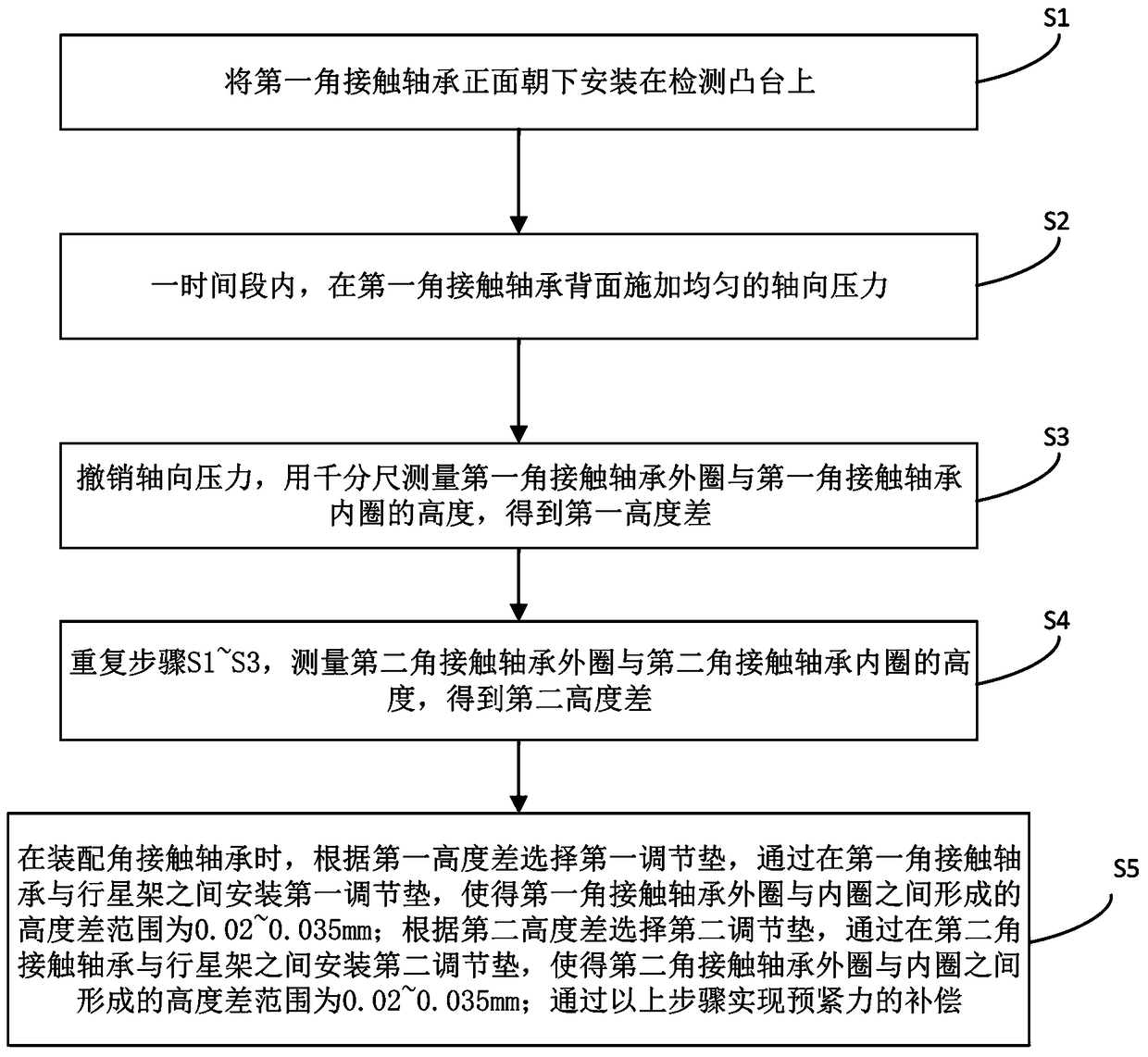

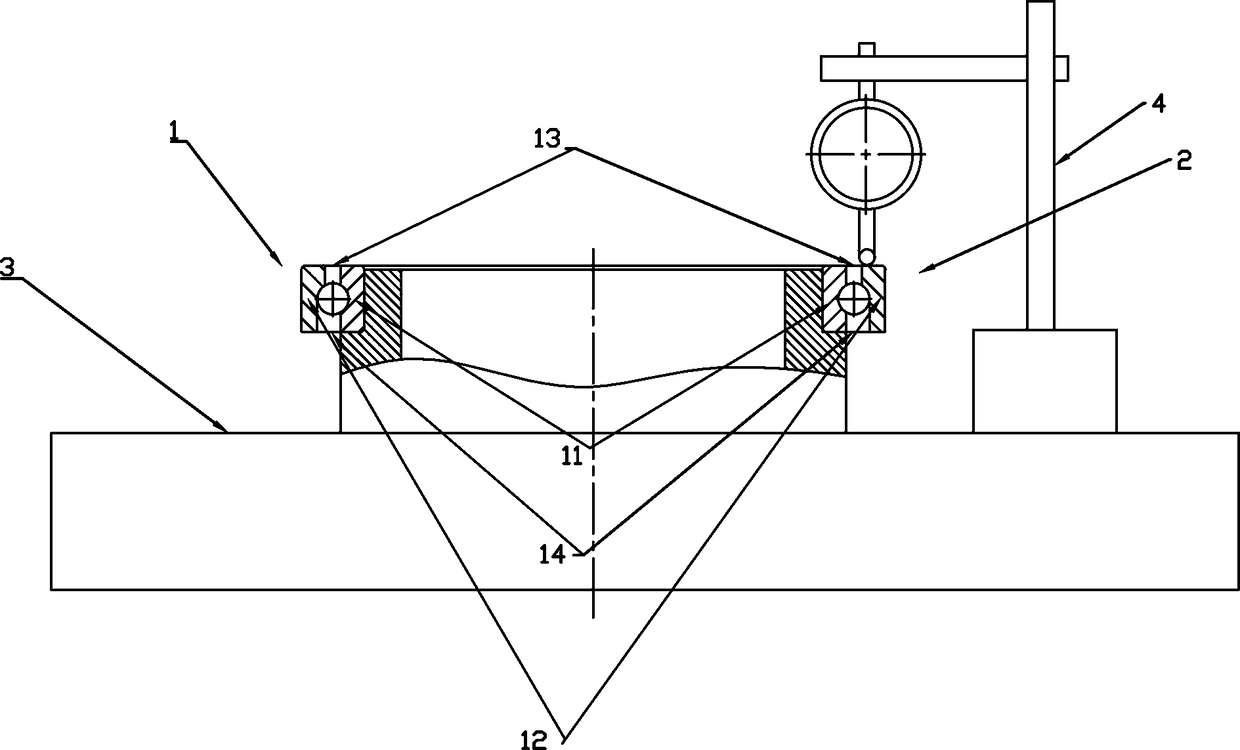

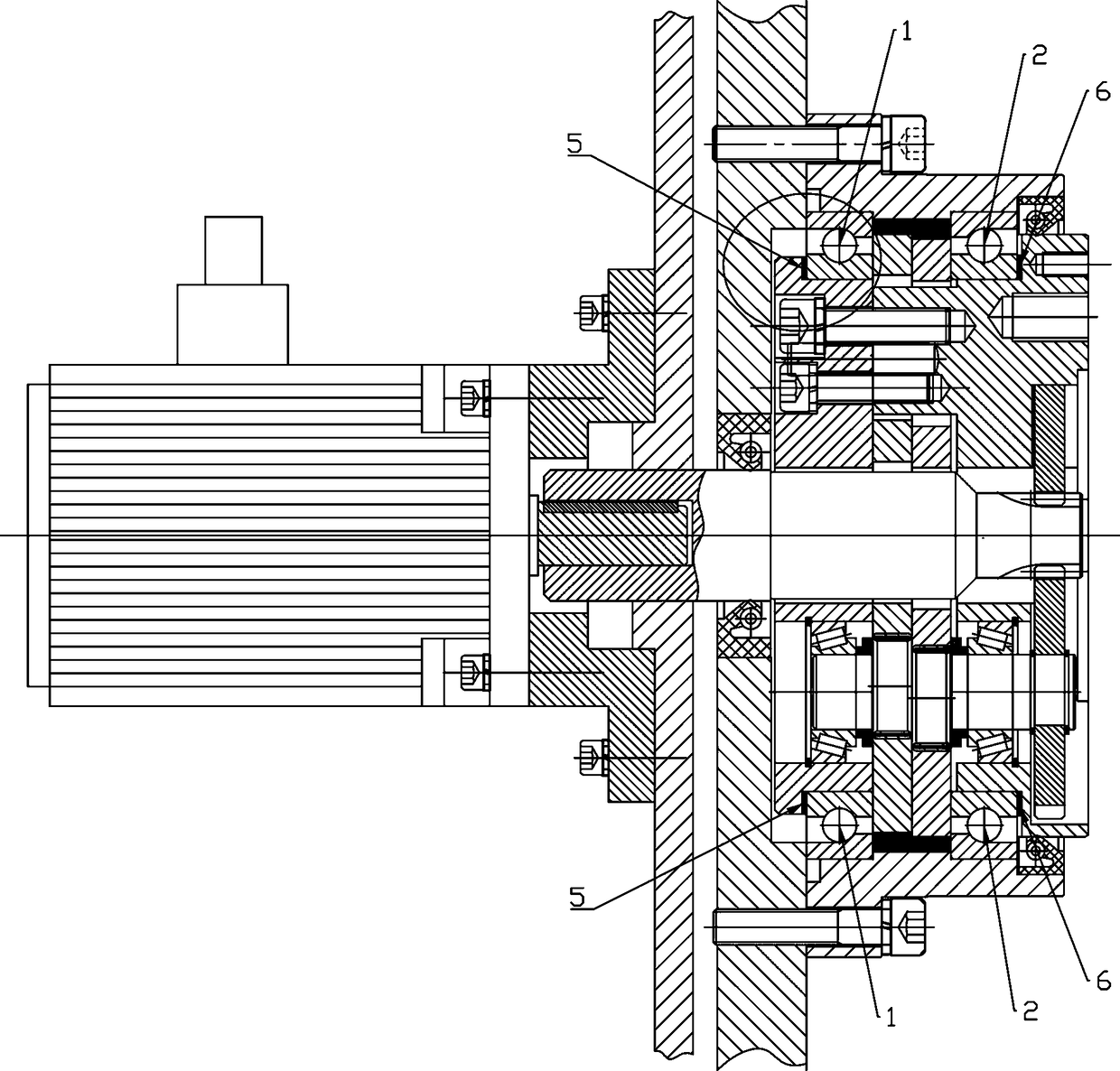

[0031] Such as figure 1 and figure 2 , figure 1 It is a schematic flow chart of the quick assembly method of the angular contact bearing of the present invention, figure 2 It is a schematic diagram of bearing detection of the present invention, and the method includes the following steps:

[0032] S1: Install the first angular contact bearing face down on the detection boss.

[0033] Before installing the angular contact bearing, due to the manufacturing error of the angular contact bearing itself, first check the accuracy of the angular contact bearing itself. In a specific real-time scenario, the inner ring of the angular contact bearing is attached to the high-speed rotating planetary shaft, and the outer ring is close to the housing. The height of the inner ring of the angular contact bearing is deliberately designed to be higher than that of the outer ring of the angular contact bearing. The height of the bearing should be short so that the adjusting pad can be inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com