Circumference equal dividing positioning hole tool for flange workpiece

A technology for positioning holes and flange clamps, which is applied in the direction of drilling dies for workpieces, etc., can solve the problems of increasing the difficulty of drilling dies, waste of labor costs, and high processing costs, and achieves flexibility, convenience, automation, and material consumption. The effect of large, high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

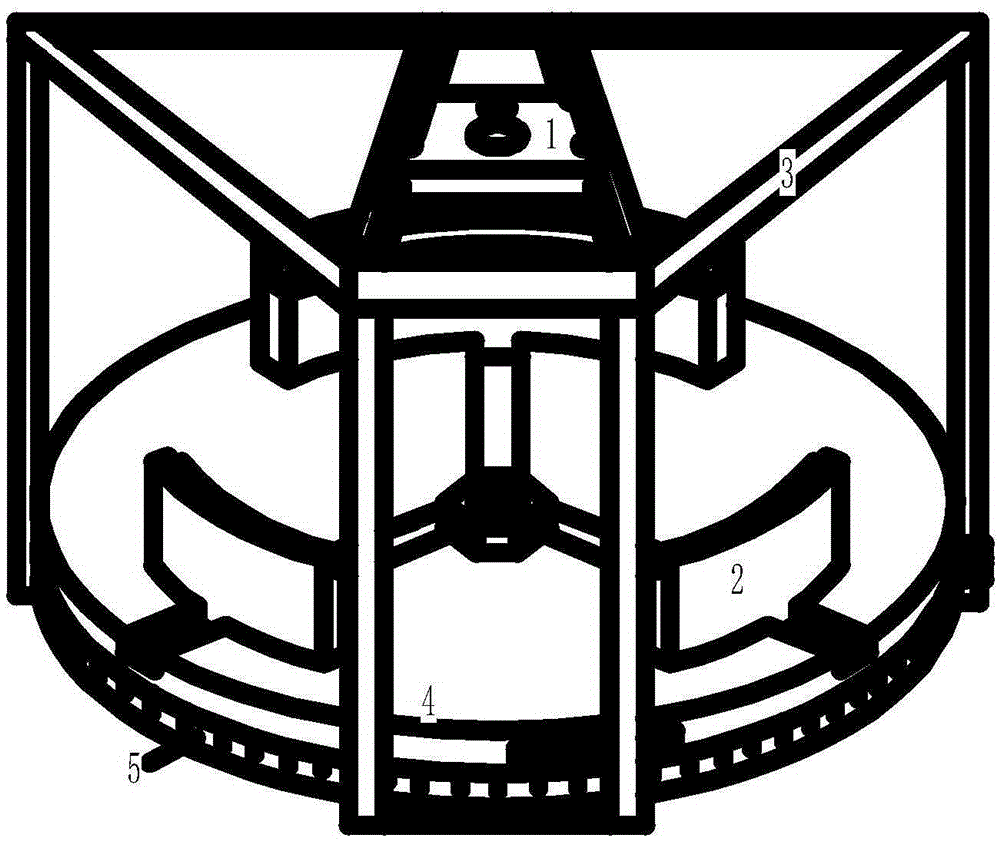

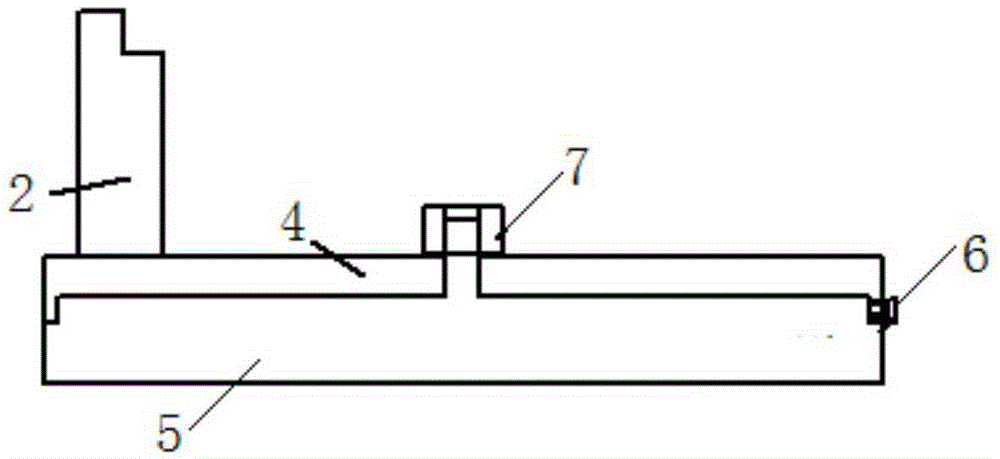

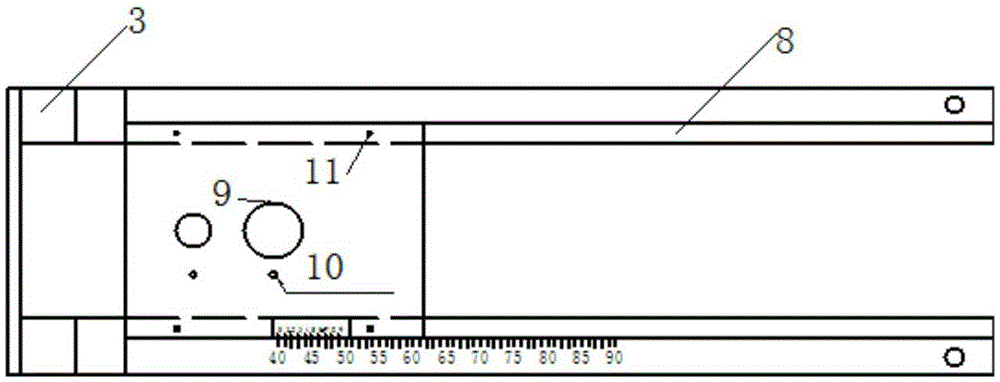

[0015] refer to figure 1 figure 2 . In the embodiment described below, the circumference of the flange-like workpiece is equally divided into the positioning hole tooling, including the lower base fixed plate 5 with graduation marks in the circumferential direction, and the fixture positioning plate 4 rotatably assembled on the lower base fixed plate 4 , wherein: the circumferential body of the base fixed plate 5 is formed with columns distributed along the circumference and a polygonal support 3 formed around the columns. Described polygonal support 3 is shaped on the slide rail 8 of sliding assembly drilling mold slide block 1, and drilling form slide block 1 can slide left and right on the longitudinal slide rail 8 of polygonal support 3, and can be fixed on polygonal support 3 by positioning screw 6 A certain position on the slide rail 8. The jig slide block 1 is formed with one or more jig jig drill bushing holes 9 of different diameters. The longitudinal edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com