Rubber sheath for automobile wire harness

A technology for rubber sheaths and automotive wiring harnesses, applied to vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of large fatigue damage and low service life, reduce fatigue, improve service life, increase The effect of fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

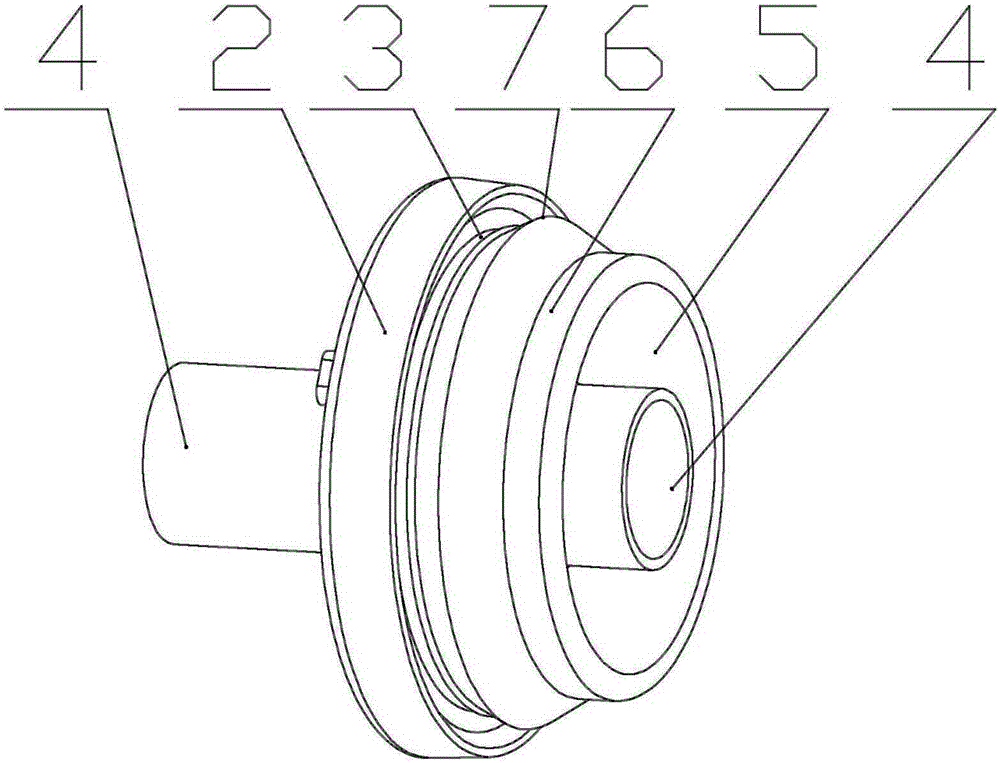

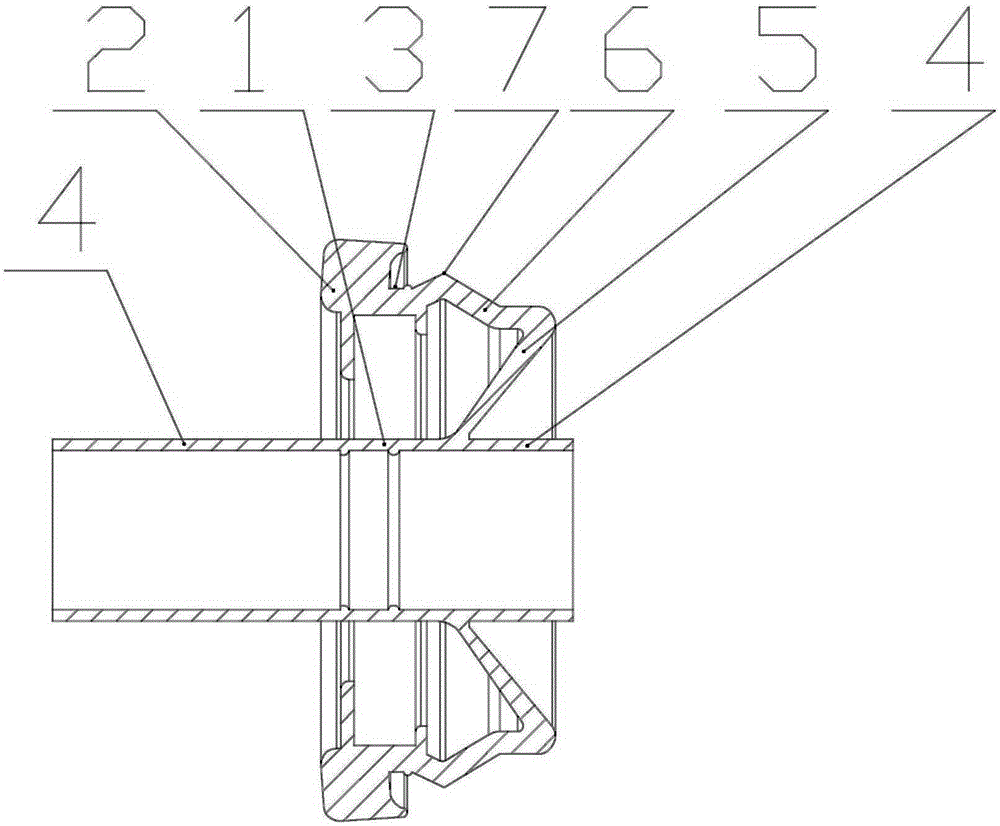

[0016] Embodiment one: if Figure 1-2 As shown, in this embodiment, the rubber sheath used for the automobile wiring harness includes a rubber body 1 provided with a through hole and a sheath 2 located outside the rubber body 1, the rubber body 1 and the sheath 2 are not Contact, the sheath 2 is provided with a groove 3 for card sheet metal, the front and rear sides of the rubber part body 1 and the edge of the through hole are provided with a sleeve 4 for fixing the wire harness, on the side of the rubber part body 1 The outer side of the sleeve is provided with a bell-shaped sleeve 5, the front edge of the bell-shaped sleeve 5 is connected to the front end of the sheath 2 through a connecting sleeve 6, and the connecting sleeve 6 is provided with folds 7 .

[0017] The cross section of the sheath 2 is a hollow concave structure inside.

[0018] The folds 7 are protrusions along the circumference of the connecting sleeve 6 .

[0019] The edge profile of the sheath 2 is a c...

Embodiment 2

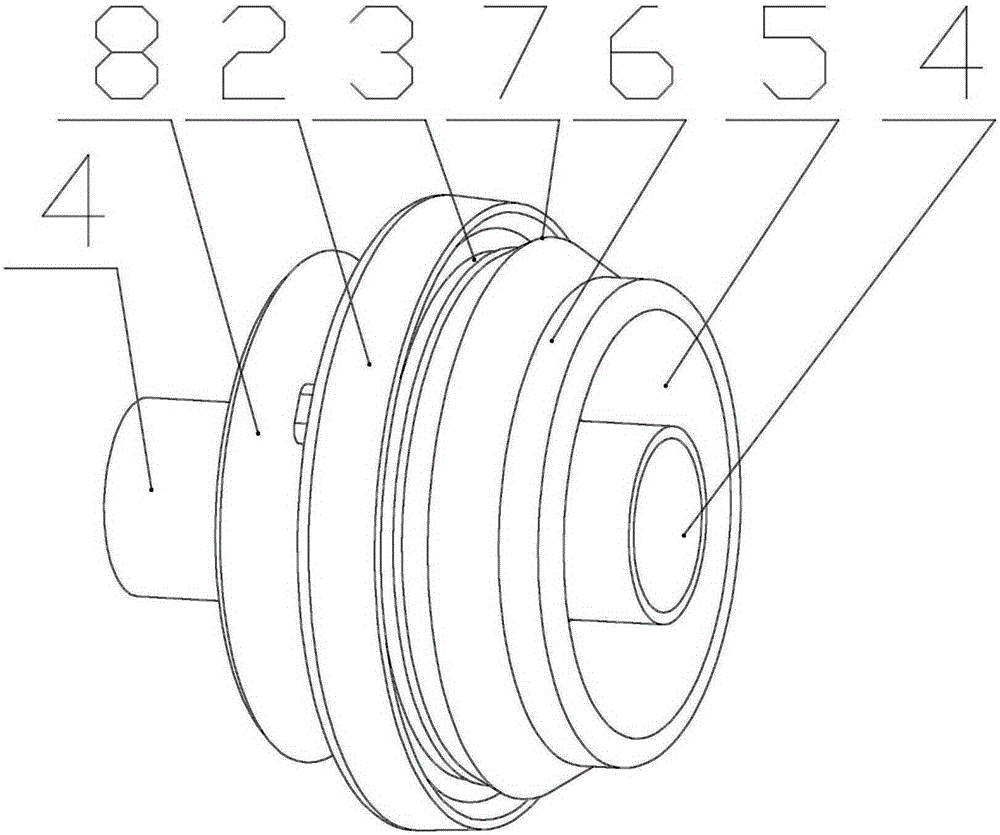

[0020] Embodiment two: if Figure 3-4 As shown, this embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that: the outer side of the sleeve 4 on the other side of the rubber body 1 is provided with a bell-shaped wire harness to limit the movement. Sleeve 8, the wire harness movement limiting sleeve 8 is located at the rear side of the sheath 2 .

[0021] The specific installation methods of rubber sheaths for automotive wiring harnesses include:

[0022] Step 1: Pass the wire harness through the through hole of the rubber part body 1, and wrap the wire harness and the sleeve 4 with adhesive tape at both ends;

[0023] Step 2: Use the groove 3 on the sheath 2 to clamp the edge of the sheet metal hole on the body sheet metal and fix it, and the assembly is completed.

[0024] When the vehicle is bumping, the force generated by the swing of the wire harness is partially buffered by the folds 7 on the connecting sleeve 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com