Electric power steering system

A technology of electric power steering and electric motor, which is applied in the direction of electric steering mechanism, etc., can solve the problems of stable use and increased maintenance cost, and achieve the effect of flexible assembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

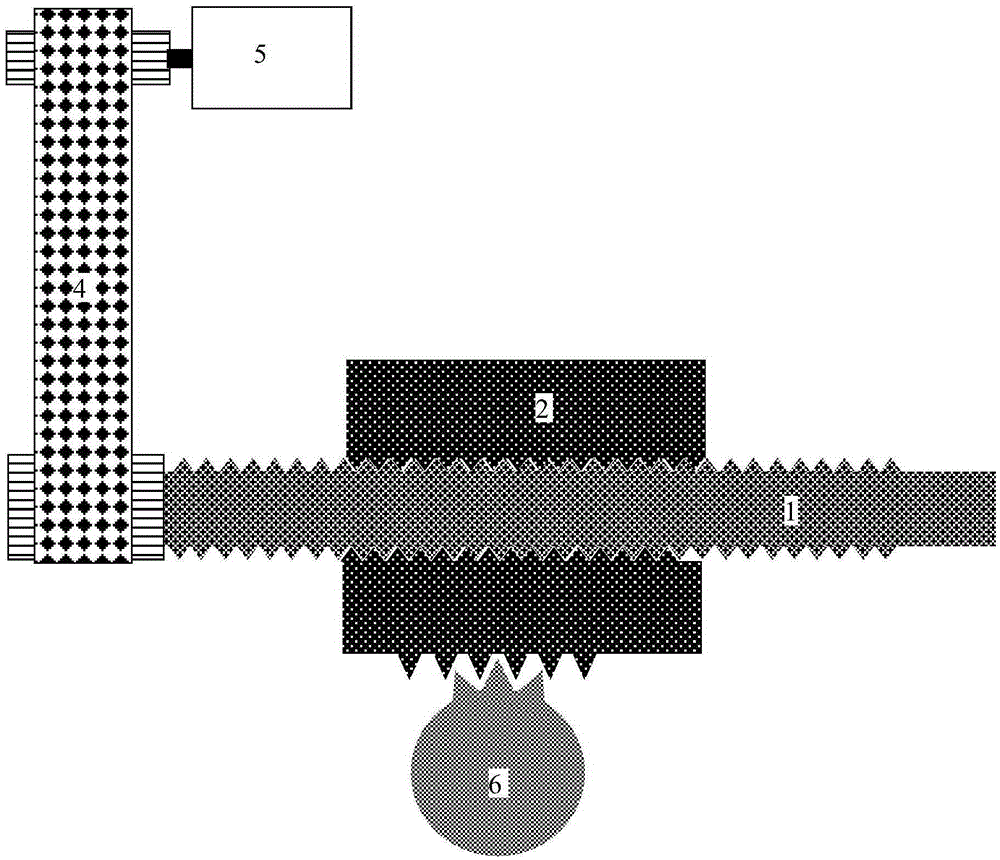

[0035] electric power steering systems such as figure 1 As shown, it includes ball screw 1, ball nut 2, motor 5, swing arm 6;

[0036] The ball nut 2 is adapted to the ball screw 1, its circumferential rotation is limited and it moves axially along the ball screw 1 with the positive and negative rotation of the ball screw 1;

[0037] The outer edge of the ball nut 2 is provided with external teeth;

[0038] The outer edge of one end of the swing arm 6 is provided with external teeth;

[0039] The external teeth provided at one end of the swing arm 6 mesh with the external teeth provided on the outer edge of the ball nut 2, so that the other end of the swing arm 6 can swing with the axial movement of the ball nut 2;

[0040] The motor 5 is used to drive the ball screw 1 to rotate;

[0041] The ball screw 1 is connected with the steering wheel.

[0042] Preferably, the ball screw 1 is elastically connected to the steering wheel through the input shaft, so as to better match ...

Embodiment 2

[0045] Based on the first embodiment, the electric power steering system further includes a first driving element and a second driving element;

[0046] The first driving element is coaxially combined with the output shaft of the motor 5;

[0047] The second driving element is coaxially combined with the ball screw 1;

[0048] The motor 5 drives the ball screw 1 to rotate through the first driving element and the second driving element.

[0049] Preferably, the first driving element is a gear;

[0050] The outer edge of the second drive element is uniformly provided with external teeth that can be adapted to the gear along the axial direction.

[0051] Preferably, the first driving element is a worm;

[0052]The second driving element is a worm gear adapted to the worm.

[0053] Preferably, the drive belt 4 is used for transmission between the first drive element and the second drive element;

[0054] The motor 5 drives the ball screw 1 to rotate through the matched first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com