Novel exhaust valve

An exhaust valve, a new type of technology, applied in the direction of valve device, function valve type, valve for ventilation, etc., can solve the problems of low safety and stability, chemical corrosion, staff injury, etc., and achieve high safety and stability, extended The service life and the effect of avoiding chemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

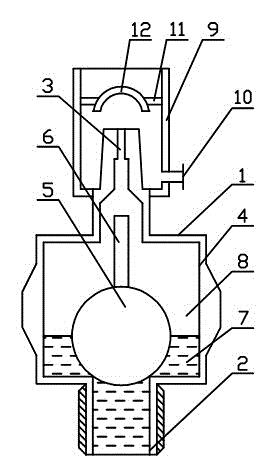

[0011] The present invention includes a valve body 1, an installation port 2, an exhaust port 3, a floating cavity 4, a floating ball 5, a connecting rod 6, a liquid 7, a gas 8, a liquid storage tank 9, a liquid discharge port 10, a mounting frame 11, a hemispherical stop Plate 12, the lower end of the valve body 1 is the installation port 2, the upper end is the exhaust port 3, the inner cavity of the valve body 1 is the floating cavity 4, the connecting rod 6 is installed on the upper end of the floating ball 5, and then the floating ball 5 is installed Inside the floating chamber 4, the connecting rod 6 is connected to the lower end of the exhaust port 3, and then a liquid discharge port 10 is opened on the liquid storage tank 9, and the hemispherical baffle 12 is installed on the liquid storage tank 9 through the mounting bracket 11. Then install the liquid storage tank 9 on the upper end of the exhaust port 3, so that the hemispherical baffle 12 is at the normal end of the...

Embodiment 2

[0013] When in use, the exhaust valve is installed on the upper end of the fluid pipeline through the installation port 2, the fluid in the pipeline enters the floating chamber 4 from the installation port 2, and the floating ball 5 moves up and down with the liquid level in the floating chamber 4, so that the connecting rod 6 Move up and down in the exhaust port 3, close or open the exhaust port 3 to exhaust, the airflow from the exhaust port 3 impacts the hemispherical baffle 12 to disperse, and overflows from the upper opening of the liquid storage tank 9 , the liquid 7 and impurities flowing into the liquid storage tank 9 are discharged through the liquid discharge port 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com