Refrigeration system capable of achieving quick precooling and ice cream machine

A freezing system and pre-cooling technology, which is applied in the field of rapid pre-cooling freezing system and ice cream machine, can solve the problems of energy consumption affecting the heat dissipation performance of the ice cream machine, increase in volume and weight of the ice cream machine, and poor pre-cooling effect, etc., to achieve shortening Improve cake making time, improve refrigeration efficiency, and shorten pre-cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

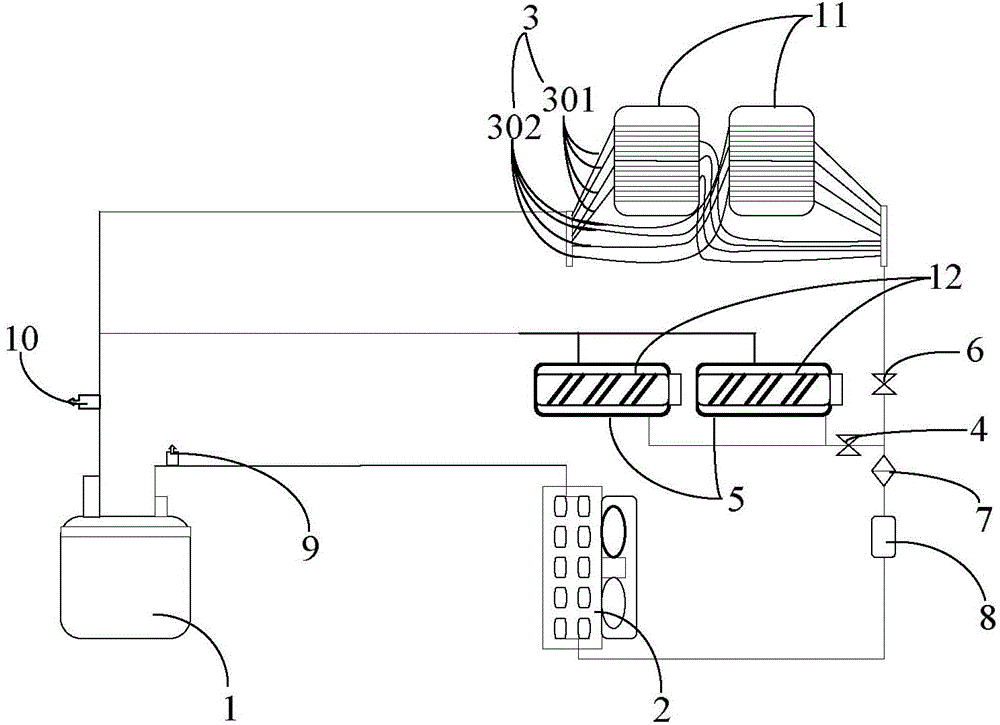

[0016] see figure 1 , the present invention provides a rapid precooling refrigeration system, including a compressor 1, a condenser 2, a precooling heat exchange element 3, a first control valve 4, a refrigeration heat exchange element 5, a second control valve 6, and an expansion valve 7 And dry filter 8, compressor 1, condenser 2, dry filter 8, expansion valve 7, first control valve 4 and refrigeration heat exchange element 5 are connected in series in sequence to form a closed cycle refrigeration circuit; compressor 1 and condenser 2. The dry filter 8, the expansion valve 7, the second control valve 6 and the pre-cooling heat exchange element 3 are connected in series in sequence to form a closed-cycle pre-cooling circuit. Wherein, the inlet end of the refrigeration heat exchange element 5 is connected with the outlet end of the expansion valve 7 through the first control valve 4, and the inlet end of the precooling heat exchange element 3 is connected with the outlet end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com