An angle-adjustable stator paint removal base

A technology for adjusting the stator and angle, which is applied in the direction of casing/cover/support, manufacturing motor generators, electrical components, etc., can solve problems affecting product quality, affecting product construction period, difficult to clean, etc., to save manpower and save The effect of time and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

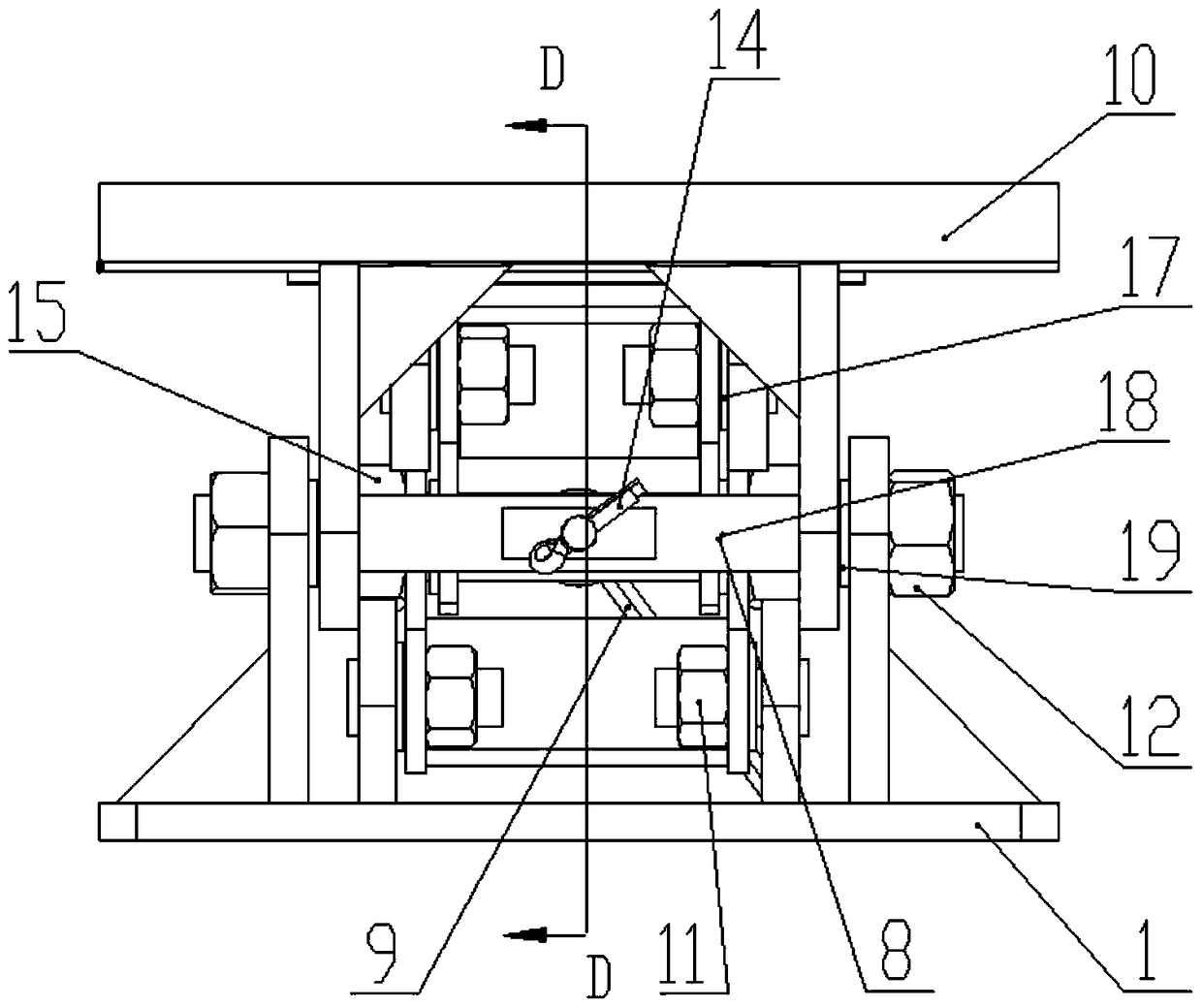

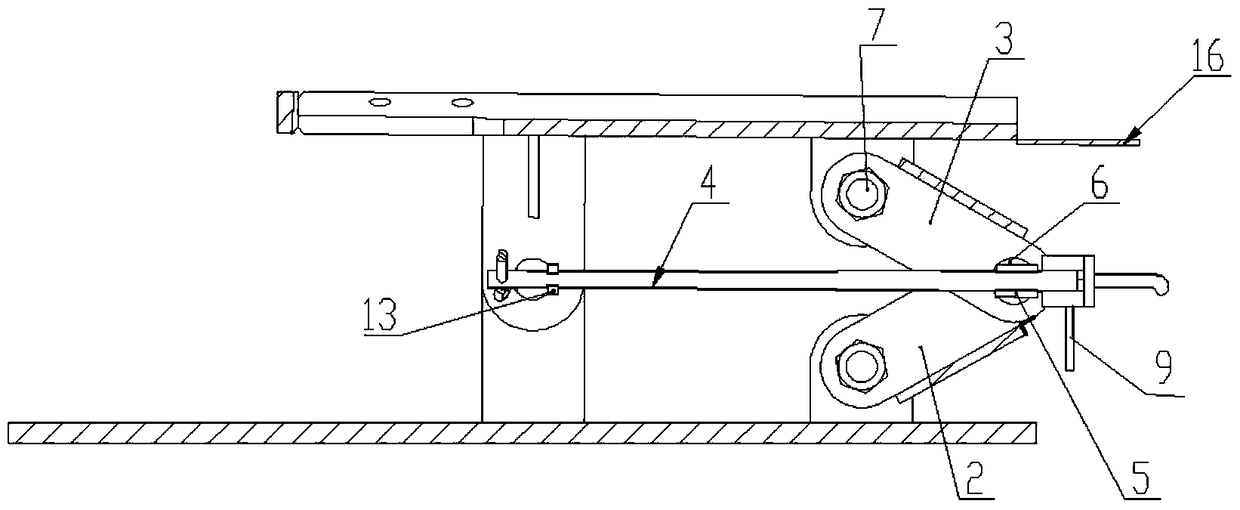

[0017] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 - Figure 6 as shown,

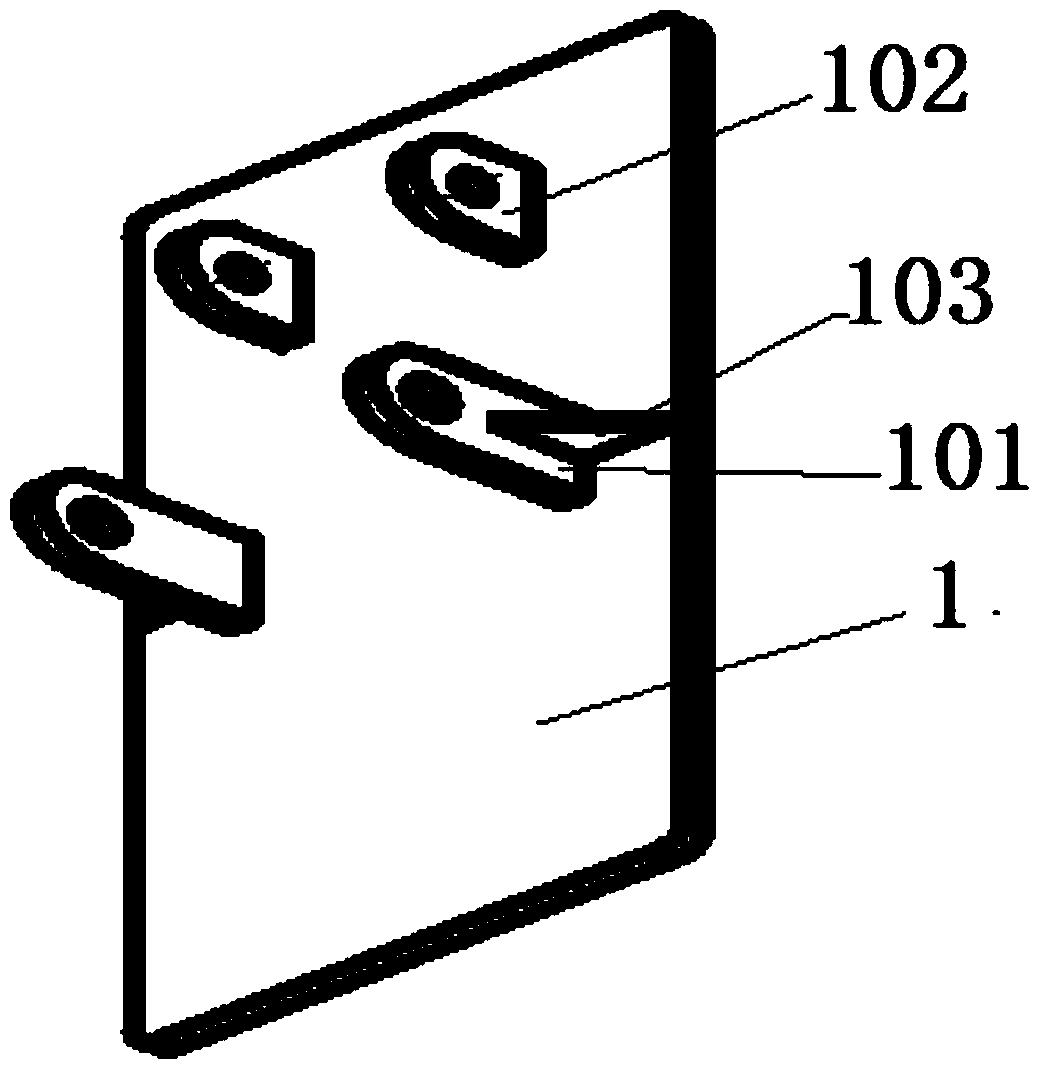

[0018] The present invention comprises a bottom plate 1, a lower support frame 2, an upper support frame 3, a long bolt 4, a nut 5, a threaded pin shaft 6, a threaded small pin shaft 7, a pin shaft 8, a curved arm handle 9, an upper connecting plate 10, Small hexagonal nut 11, medium hexagonal nut 12, washer 13, cotter pin 14, large hexagonal nut 15, supporting plate 16, flat washer 17, large washer 18, small washer 19. The front end of the base is connected together by the mounting ear-101 on the base plate 1 through the bearing pin 8 and the mounting ear-101 on the upper connecting plate 10. To ensure the strength, the mounting ear-103 is also provided with a reinforcing rib 103; The bottom end is that the lower support frame 2 is connected with the upper support frame 3 through the threaded pin shaft 6; The pin shaft 7 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com