Manufacturing method for particle Tibetan tea

A production method and granule technology, which is applied in the production of granule Tibetan tea, can solve the problems of inconvenient brewing and easy turbidity of tea soup, and achieve the effect of convenient brewing and clear red tea soup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

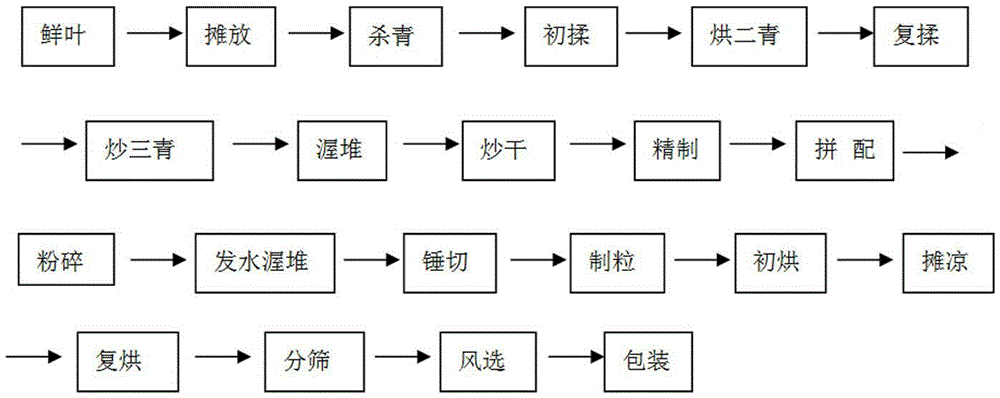

[0033] The preparation method of the granular Tibetan tea in this example is to use the fresh leaves of tea leaves as raw materials, and process the granular Tibetan tea through the following steps:

[0034] The fresh leaves of tea go through the spreading process, greening process, initial kneading process, second green drying process, re-kneading process, third green frying process, stacking process, frying and drying process, refining process, blending process, crushing process, and watering and stacking process, hammer cutting process, granulation process, initial drying process, cooling process, re-drying process, sieving process, winnowing process and packaging process to obtain the finished granule Tibetan tea.

[0035] The spreading process is as follows: thinly spread the fresh tea leaves within 5 leaves of a bud on the bamboo mat, the thickness of the fresh tea leaves is 20 cm, and the spreading time is 12 hours to obtain the spreading leaves; the spreading time canno...

Embodiment 2

[0056] The preparation method of the granular Tibetan tea in this example is to use Tibetan tea loose tea as raw material, and process the granular Tibetan tea through the following procedures:

[0057] The Tibetan tea loose tea is crushed, watered and heaped, hammered and cut, granulated, first baked, cooled, rebaked, sieved, wind-selected and packaged to obtain the finished product of Tibetan tea granules.

[0058] The pulverizing process is as follows: the Tibetan tea loose tea is pulverized into tea powder with a mesh number of 120 through a pulverizer.

[0059] All the other procedures are with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com