Impact type diaphragm micro jet dispensing device

A dispensing device and impact-type technology, which is applied in the field of impact-type diaphragm micro-spray dispensing devices, can solve problems such as nozzle wear, increased maintenance costs of jet dispensing devices, and liquid material changes, so as to avoid severe wear and direct Contact, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

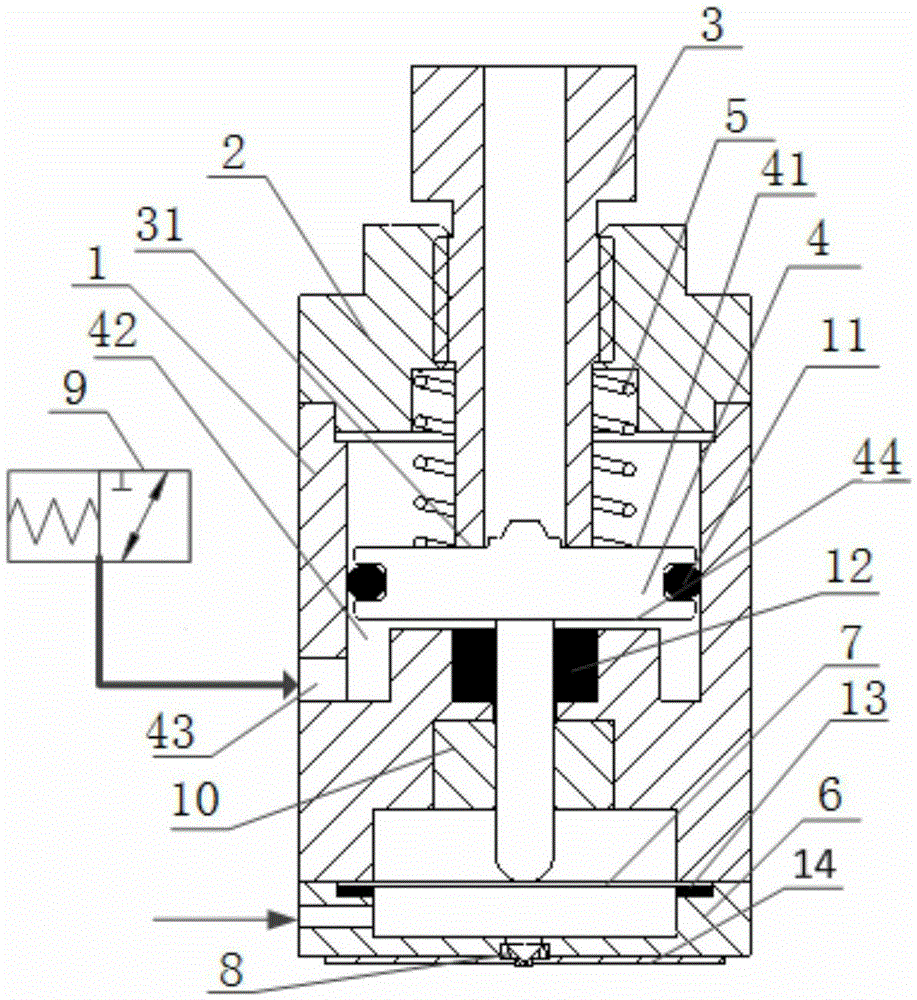

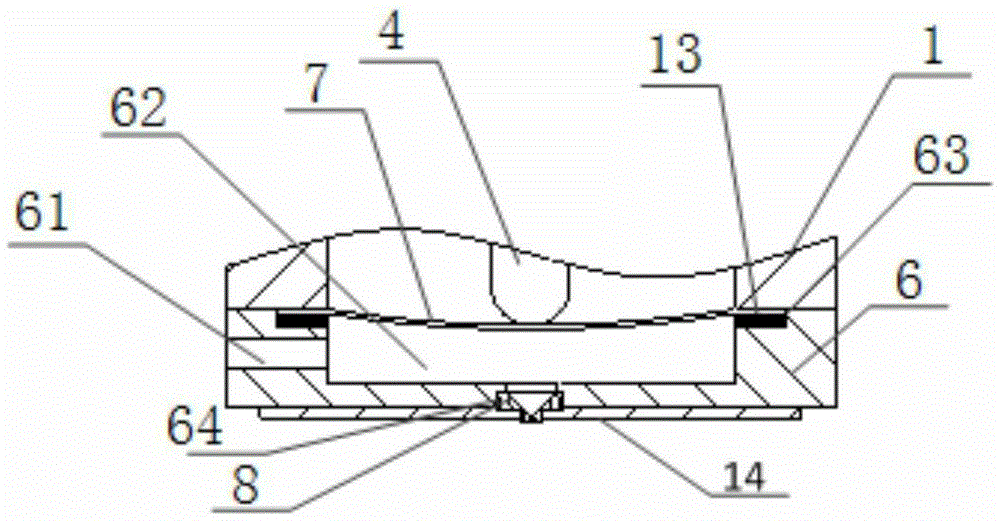

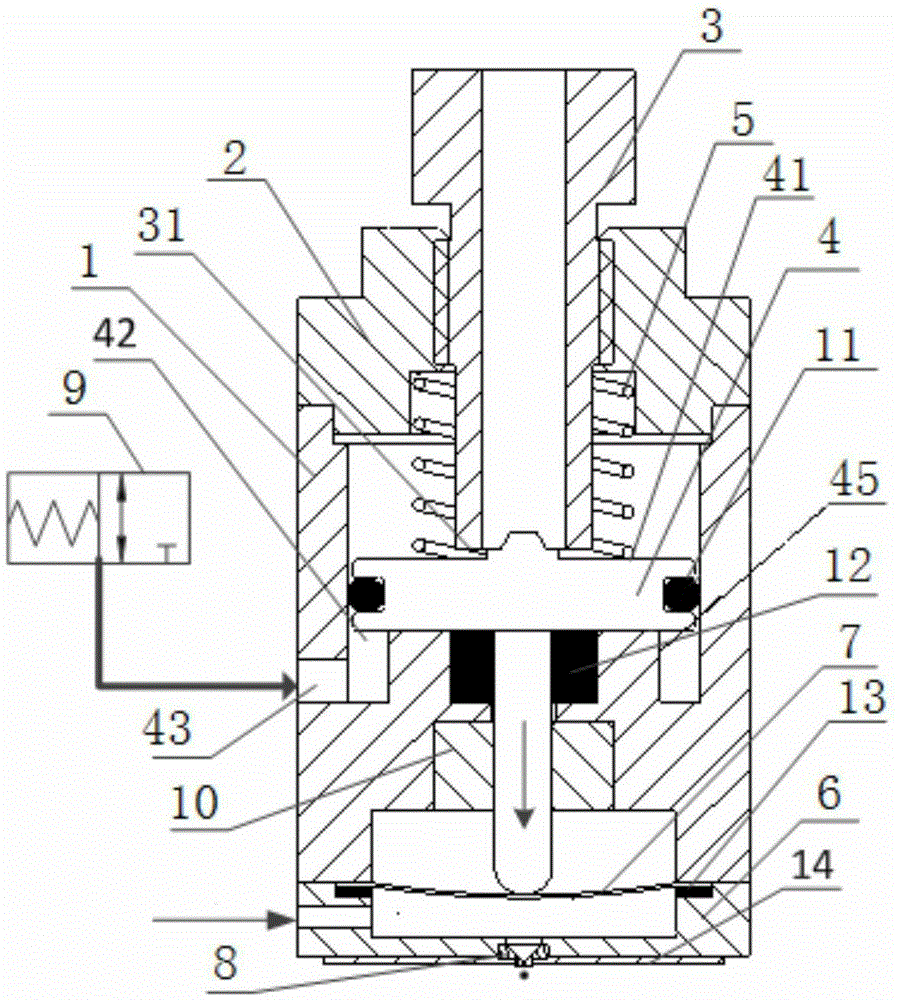

[0018] Such as figure 1 As shown, the present invention discloses an impact-type diaphragm micro-spray dispensing device, including a cylinder 1, a gland 2, a stroke adjustment rod 3, a piston rod 4, a spring 5, an injection chamber 6, a diaphragm 7, a nozzle 8 and High-frequency solenoid valve 9, gland 2 is installed above the cylinder 1, the stroke adjustment rod 3 is installed in the gland 2 through threads, the piston rod 5 is installed in the cylinder 1, and the spring 5 is installed between the gland 2 and the piston rod 4 Between, the spring 5 is pressed on the upper end surface 41 of the piston rod, the piston rod 4 is located under the stroke adjustment rod 3, the injection chamber 6 is installed under the cylinder 1, and the diaphragm 7 is sandwiched between the injection chamber 6 and the cylinder 1, The diaphragm 7 is located below the piston rod 4 , the nozzle 8 is installed on the lower end surface of the injection chamber 6 , and the high-frequency solenoid valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com