Adjustable Roll Groove Cooling Device

A cooling device and adjustable technology, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of difficult roll cooling, achieve the effect of prolonging the service life and maintaining the surface quality of the rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

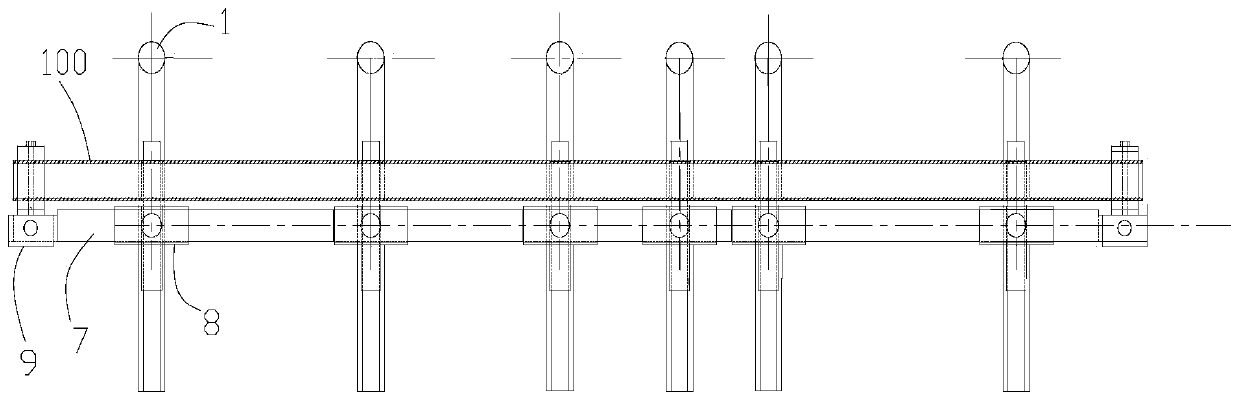

[0030] like figure 1 As shown, the embodiment of the present invention includes a plurality of annular cooling branch pipes distributed in parallel transversely along the length direction of the support beam 7 and a water collecting pipe 100, a bracket, a support beam 7, and a sliding frame 8 matched with each branch pipe 1 or branch pipe 4 .

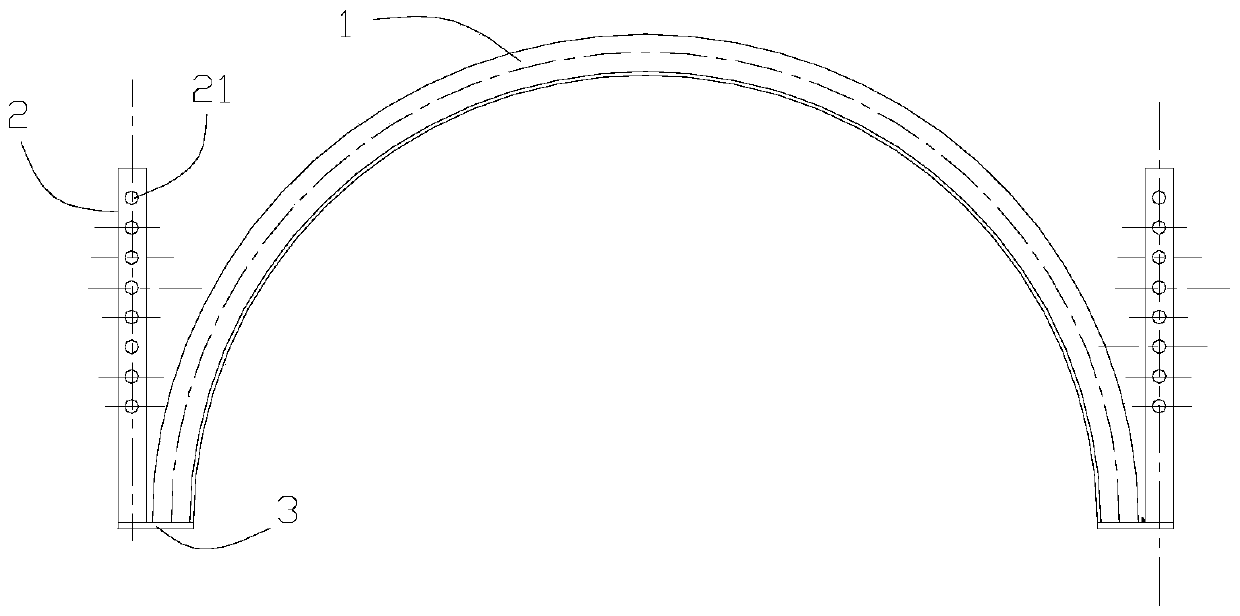

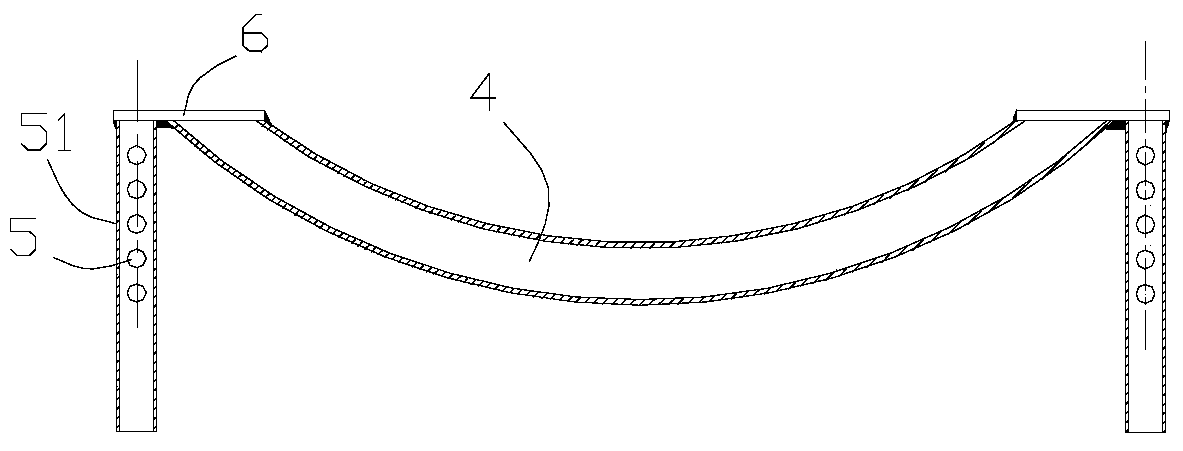

[0031] The first branch pipe 1 and the second branch pipe 4 of the annular cooling branch pipe; the first branch pipe 1 and the second branch pipe 4 are arc-shaped, wherein the branch pipe 1 is located above the upper roller, and the second branch pipe 4 is located below the lower roller. When a first branch pipe 1 and a second branch pipe 4 are arranged around the roll groove, after being arranged up and down around the roll, they are basically a circle, and the two can basically cover the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com