Pickup devices and robots

A suction device and suction cup technology, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of weakening vacuum degree, insufficient vacuum degree of vacuum suction cup, and influence of vacuum suction cup, so as to improve stability and reliability and increase suction success rate, increase the effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

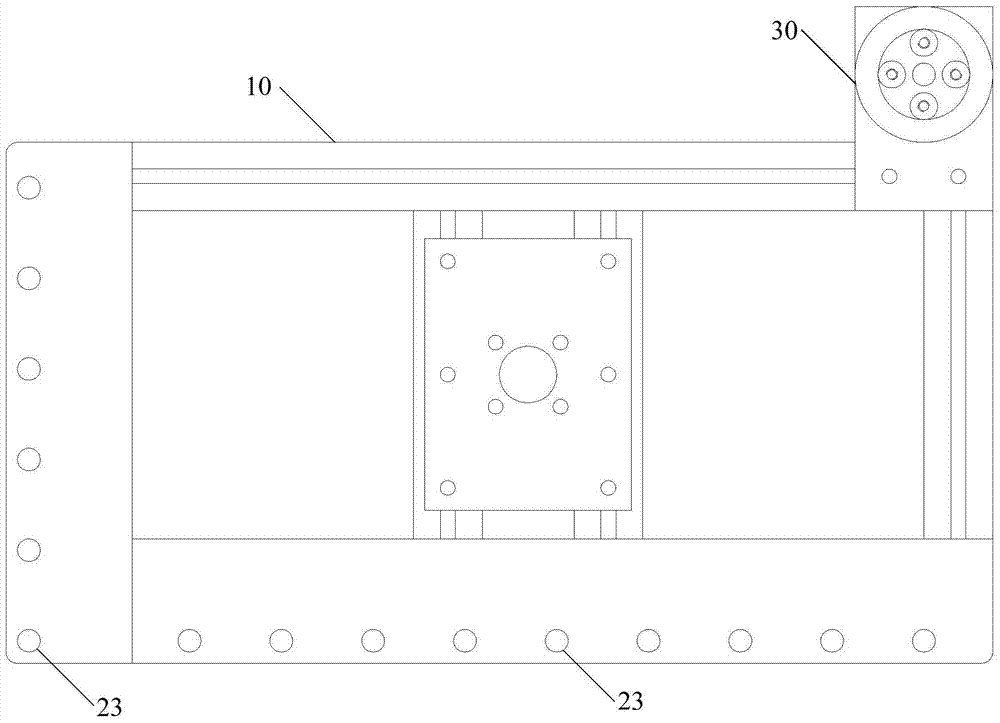

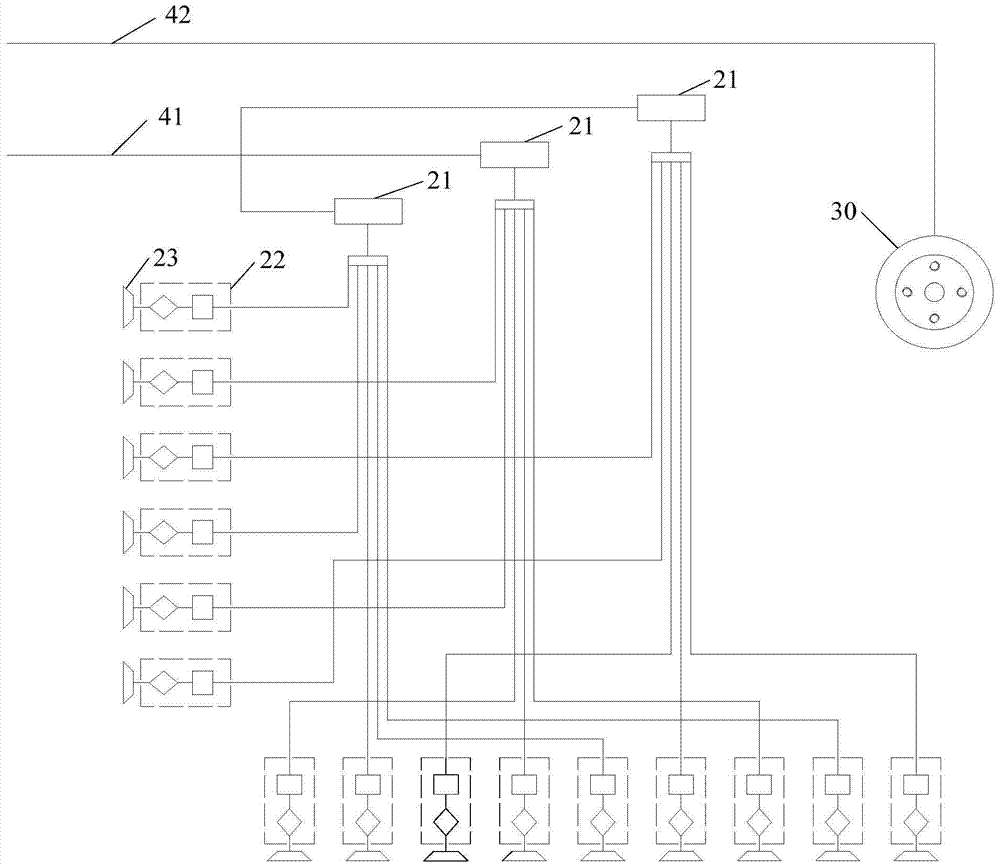

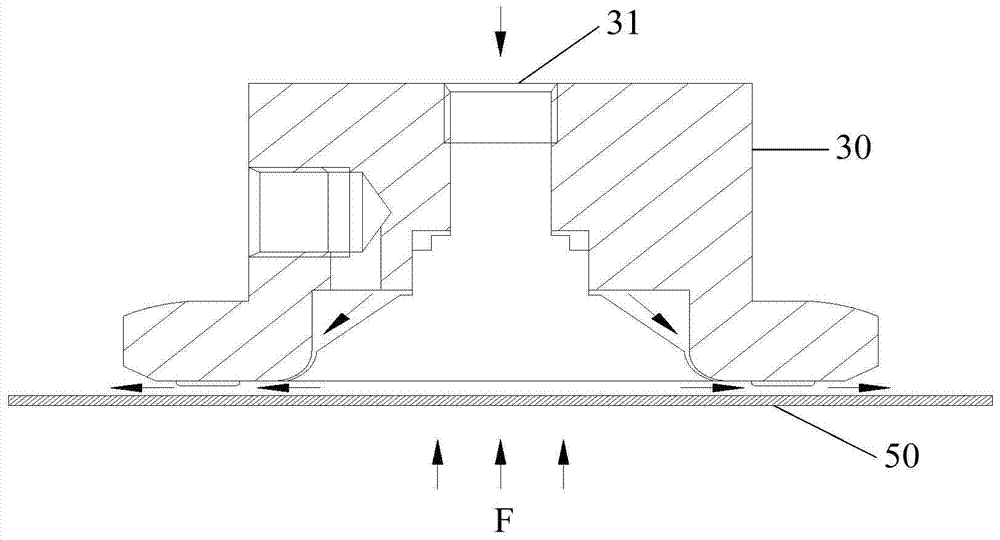

[0023] see Figure 1-Figure 3 , propose a first embodiment of the suction device of the present invention, wherein figure 1 It is a structural schematic diagram of the first embodiment of the suction device of the present invention, figure 2 It is a schematic diagram of the gas path of the suction device of the embodiment of the present invention; image 3 It is a working principle diagram of the non-contact suction cup according to the embodiment of the present invention. The suction device is applied to an automatic processing robot, and is mainly used for suctioning a flat plate with holes (such as a printed circuit board with holes). The suction device includes a substrate 10 and a vacuum suction component installed on the substrate 10 , the vacuum suction component includes at least two vacuum generators 21 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com