A paper receiving and pulling device and its working method

A technology of paper-pushing device and working method, which is applied in the direction of transportation and packaging, sending objects, and thin material processing, etc., which can solve the problems of poor paper collection, chaotic paper shutdown, and unsmooth movement, etc., and achieves a compact mechanical structure and a reasonable space. , the effect of reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

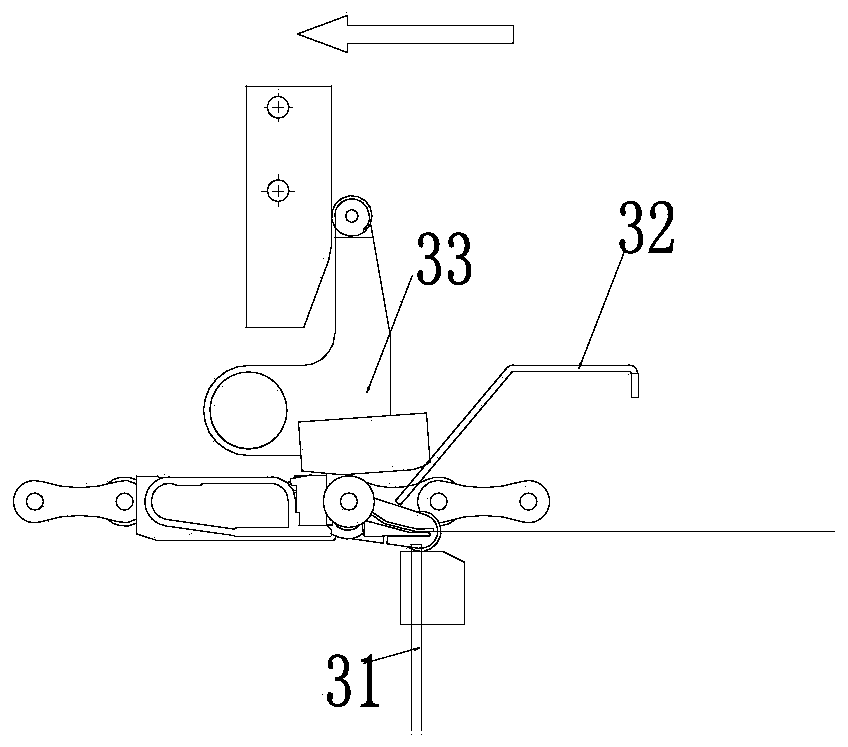

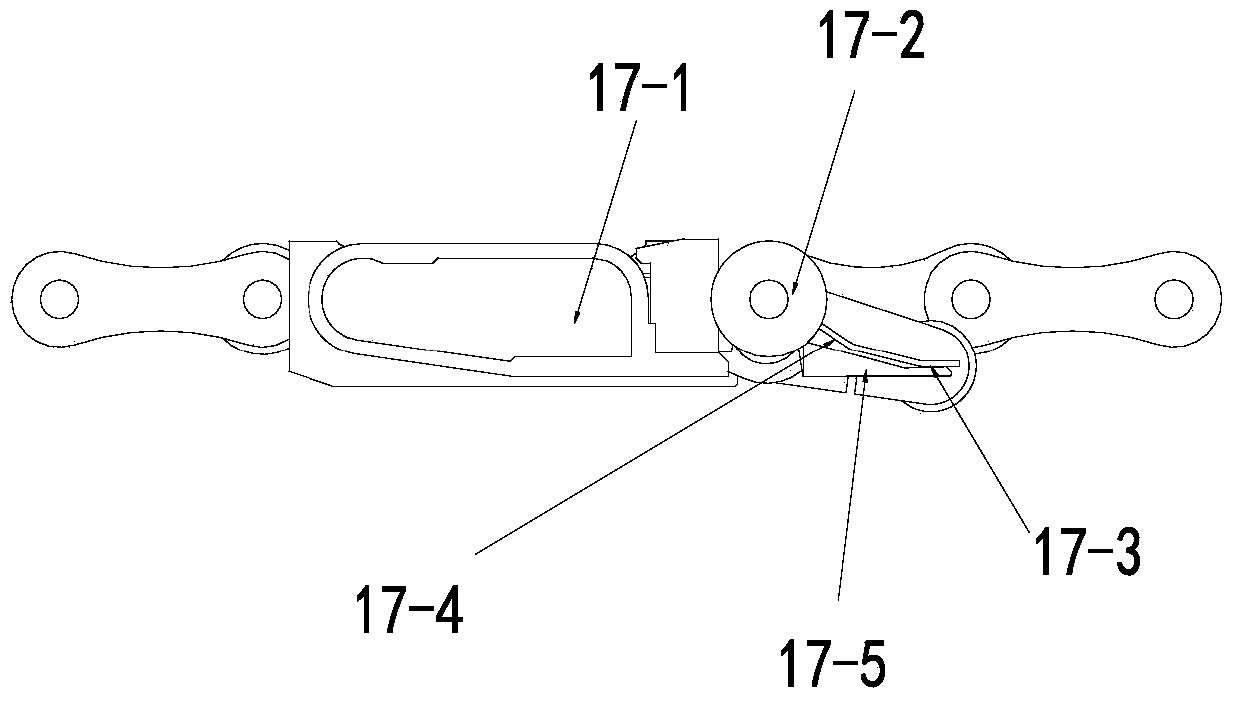

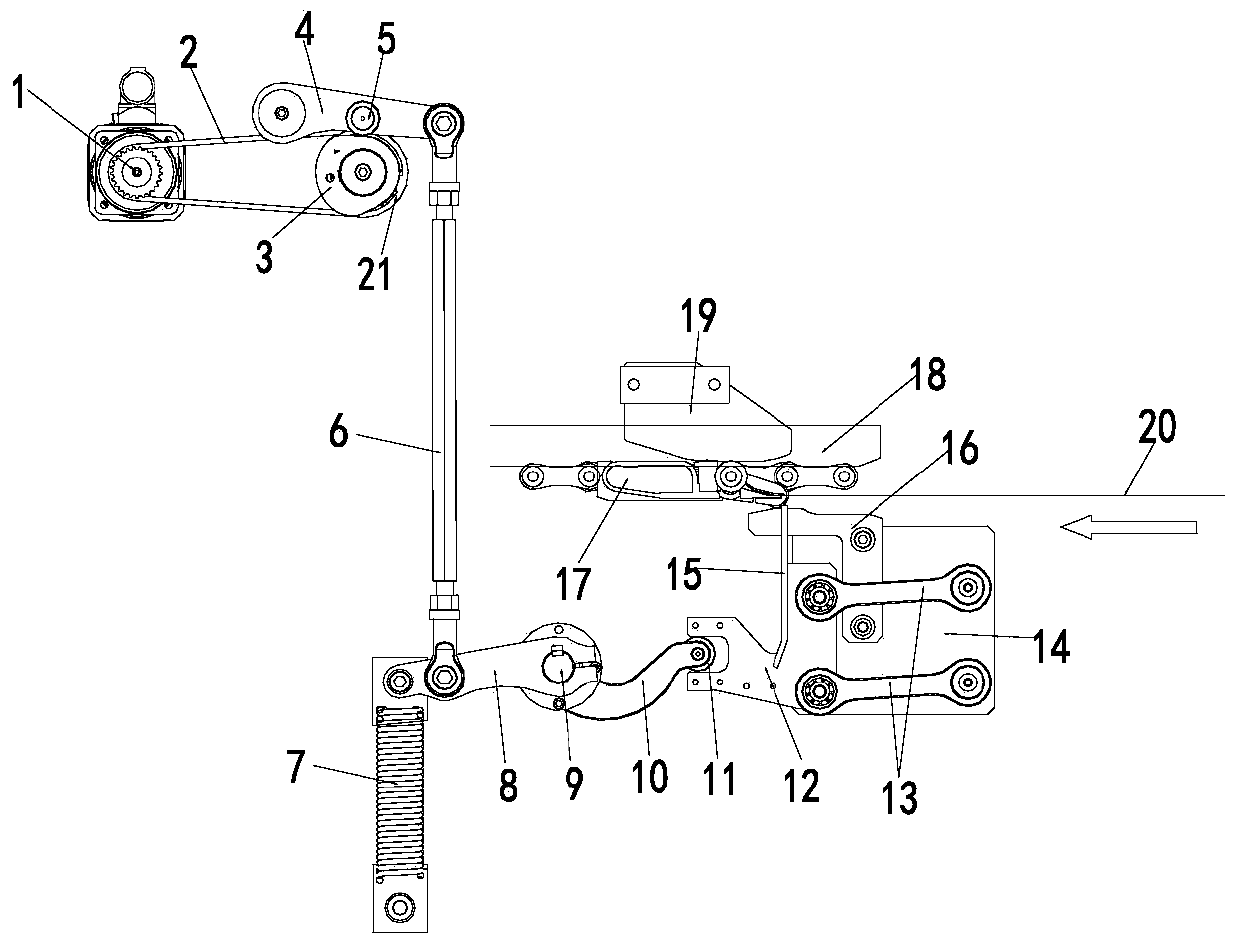

[0031] Embodiment: a kind of paper receiving and pulling device (see image 3 ), including the row of teeth 17, characterized in that it also includes a drive unit, connecting plate 12, connecting rod III13, fixed plate 14, paper blocking plate 15 and tooth opening block 16; the drive unit is connected with the connecting plate 12; The swing end of the connecting rod III13 is hingedly connected to the connecting plate 12, and the fixed end of the connecting rod III13 is hingedly connected to the fixing plate 14; the paper blocking plate 15 is fixed on the connecting plate 12, and the opening block 16 is fixed on the fixing plate 14; The connecting plate 12, the connecting rod III 13 and the fixed plate 14 form a four-bar linkage.

[0032] The connecting plate 12 can swing up and down with the fixed end of the connecting rod III13 as the axis. (See image 3 )

[0033] The drive unit is mated with the connecting plate 12 through the transmission unit. (See image 3 )

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com