Inner barrel of cement preheater

A cement preheater and inner cylinder technology, applied in the directions of preheating cost, lighting and heating equipment, furnaces, etc., can solve the problems of reduced service life, poor sealing of connection gaps, fast flow rate, etc. Protection from corrosion, erosion force reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, but do not limit protection scope and application scope of the present invention:

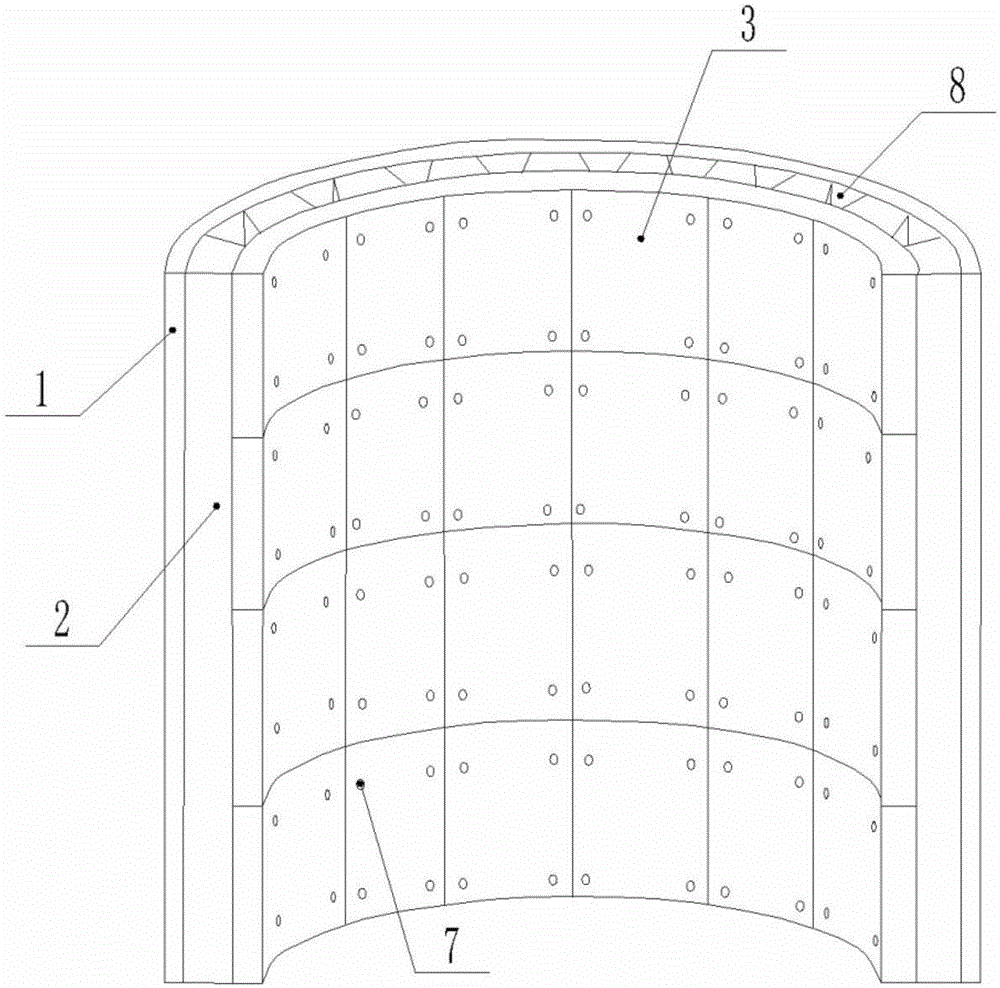

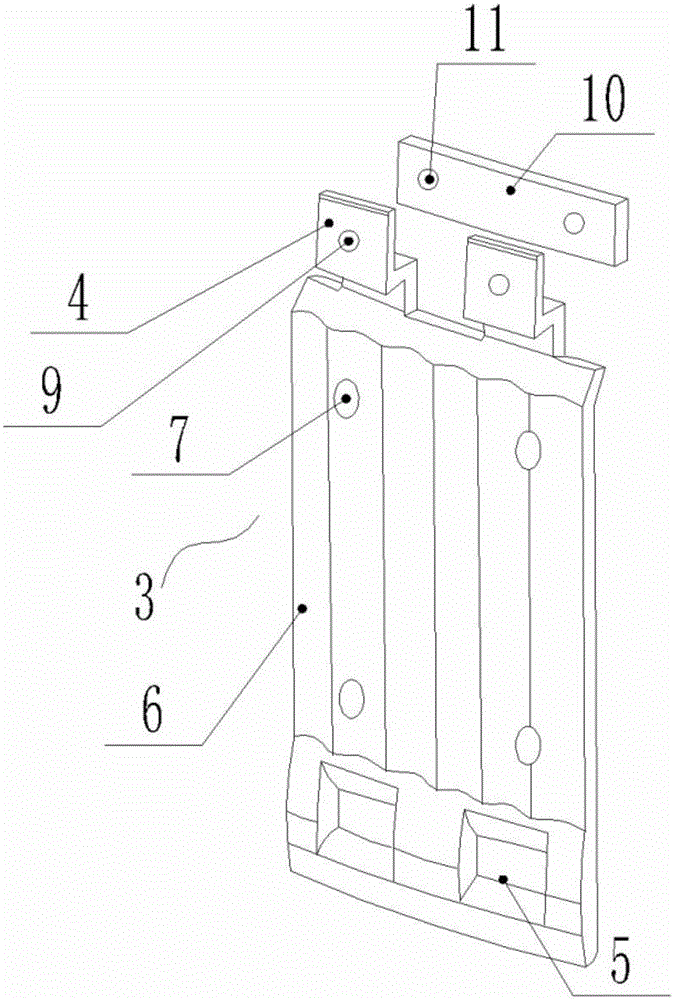

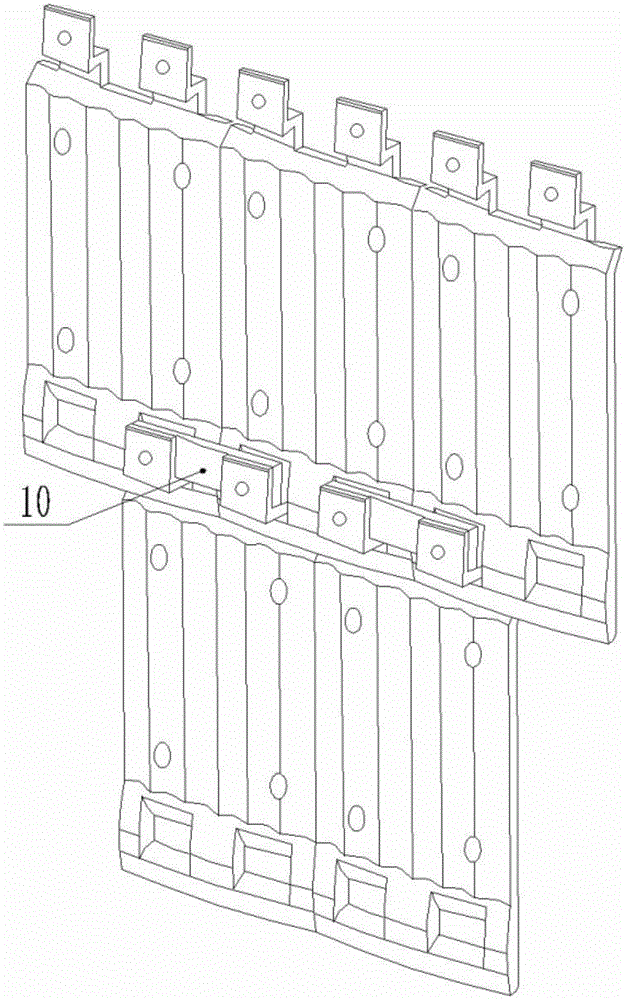

[0013] like figure 1 , figure 2 , image 3 As shown, the inner cylinder of a cement preheater includes a cylinder body 1, the inner wall of the cylinder body 1 is equipped with a buffer layer 2, and the buffer layer 2 is made of high temperature resistant and corrosion resistant materials, such as stainless steel, copper etc. The buffer layer 2 is provided with a vertically penetrating hollow groove 8. The function of the hollow groove 8 is to buffer heat from reaching the cylinder body 1, reduce the corrosion amount of the cylinder body 1, and prolong the service life. The inner wall of the buffer layer 2 is equipped with an arc-shaped ceramic hanging piece 3 and a connecting block 10 for connecting the ceramic hanging piece 3, and the top of the ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com