Multipoint sampling and indicating apparatus of arch-roof tank

A technology of indicating device and vaulted tank, applied in sampling device, buoy liquid level indicator, etc., can solve the problems of high bending, inaccurate data acquisition, easy bending and breakage, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention can be explained in more detail by the following examples, the present invention is not limited to the following examples, the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention;

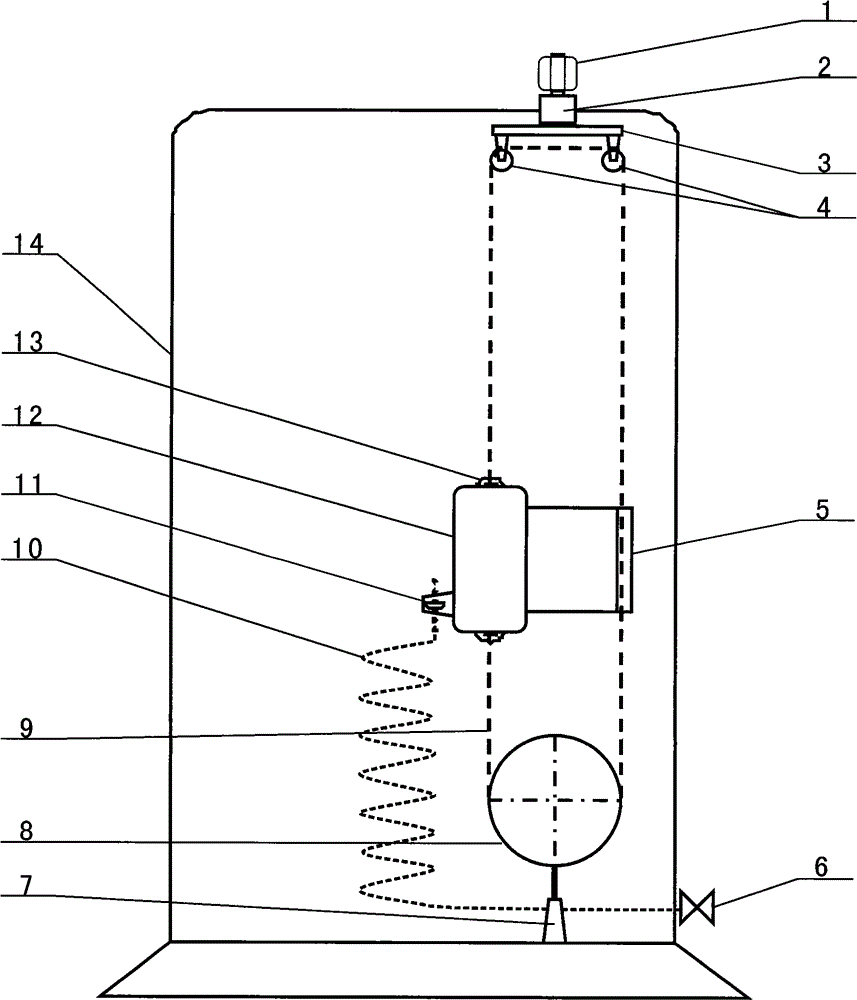

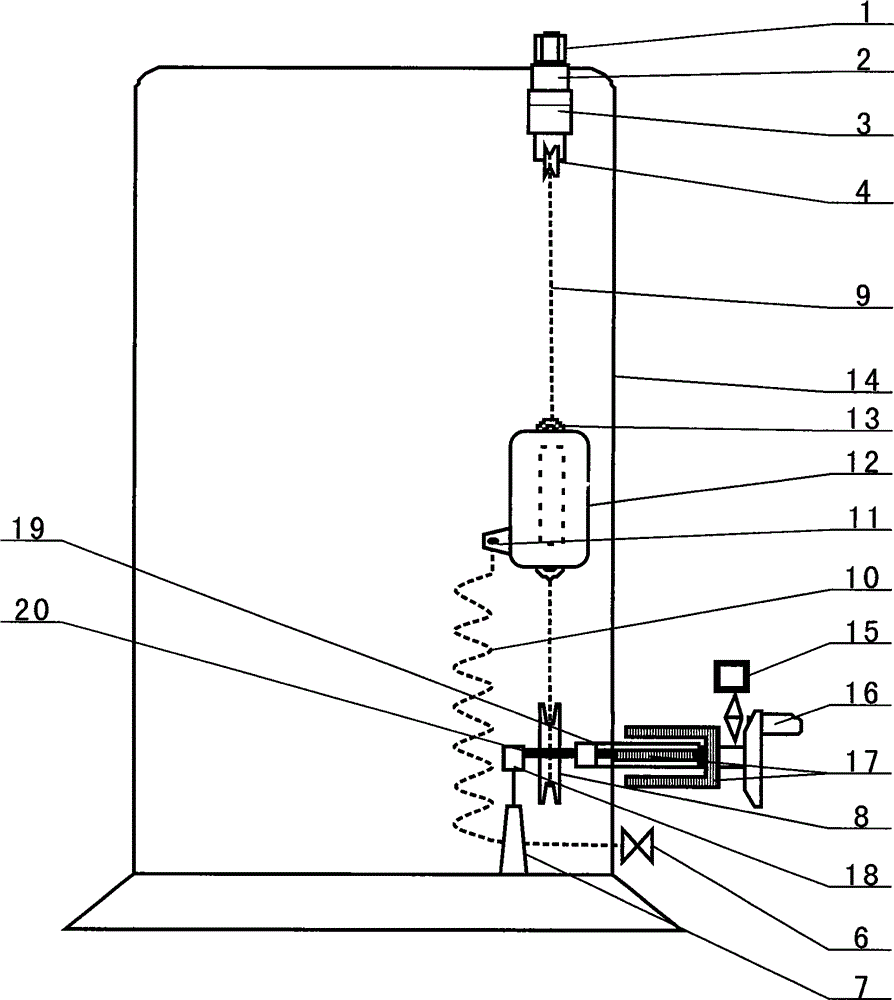

[0028] combined with figure 1 Or the multi-point sampling indicating device of the vaulted tank described in 2, comprising a vaulted tank 14, an upper fixing mechanism, a fixed seat 7, a track rope 9, a floating ball 12, a sampling oil guide pipe 10, a sampling valve 6, a rotating shaft 20, The magnetic rotor 17 and the reader 15 are respectively provided with an upper fixing mechanism and a fixing seat 7 in the vault tank 14. The upper fixing mechanism includes a tank top fixing nut 1, a tank top fixing pipe 2, and a T-shaped pulley bracket. 3 and pulley 4, tank top fixing nut 1 and tank top fixing tube 2 are fixed on the top of the vaulted tank 14, and a T-shaped pulley bracket 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com