Steel tube pulse magnetization magnetic flux leakage detecting device

A flaw detection device, pulse technology, applied in the direction of material magnetic variables, etc., can solve the problems of high cost, low practicability, large floor space, etc., and achieve the effect of compact equipment, simple structure, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

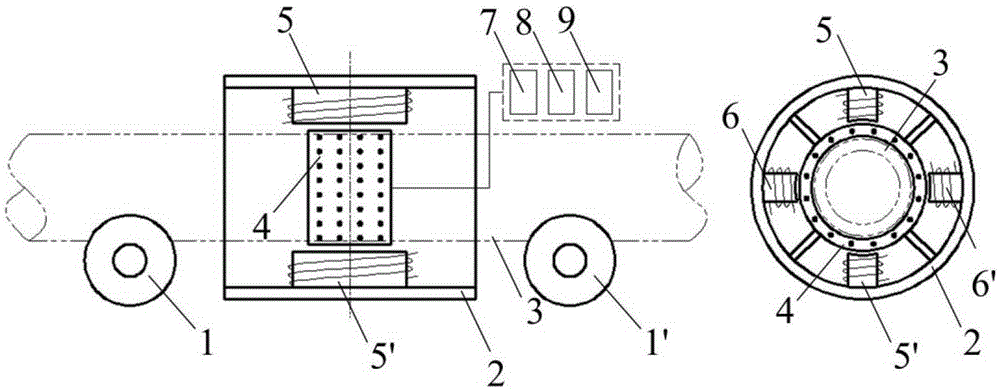

[0023] Such as figure 1 As shown, the DC pulse magnetization magnetic flux leakage flaw detection device includes: a conveying wheel 1 , a flaw detection host 2 and a steel pipe 3 . The steel pipe 3 is driven by the transmission wheel 1 and moves in a straight line. The flaw detection host 2 includes a surface array sensor 4 arranged in a 360° full circumference, vertical magnetizer groups 5 and 5', and horizontal magnetizer groups 6 and 6'. The defect leakage magnetic field is converted into an electrical signal by the area array sensor 4, and then enters the computer through the filter 7, the amplifier 8, and the A / D converter 9 in sequence.

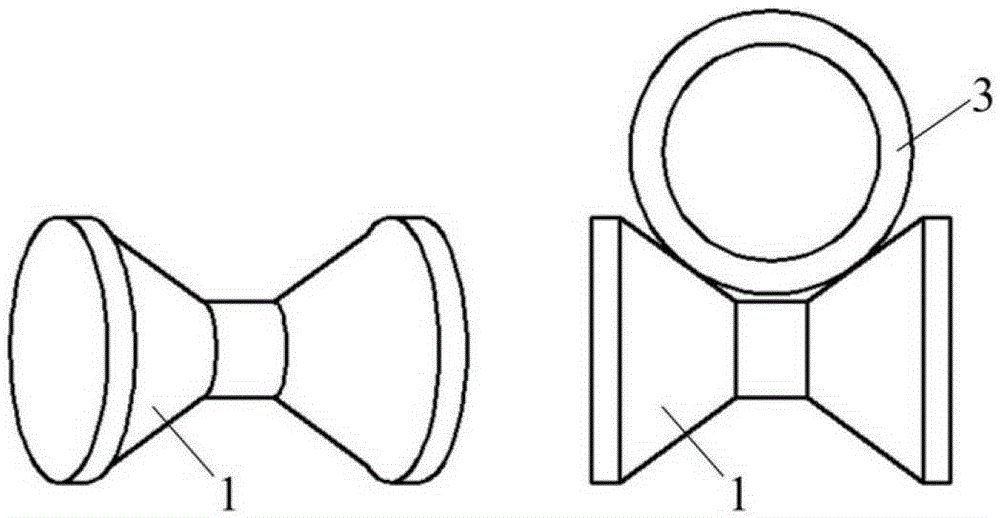

[0024] Such as figure 2 As shown, the steel pipe 3 moves linearly under the drive of the transmission wheel 1 .

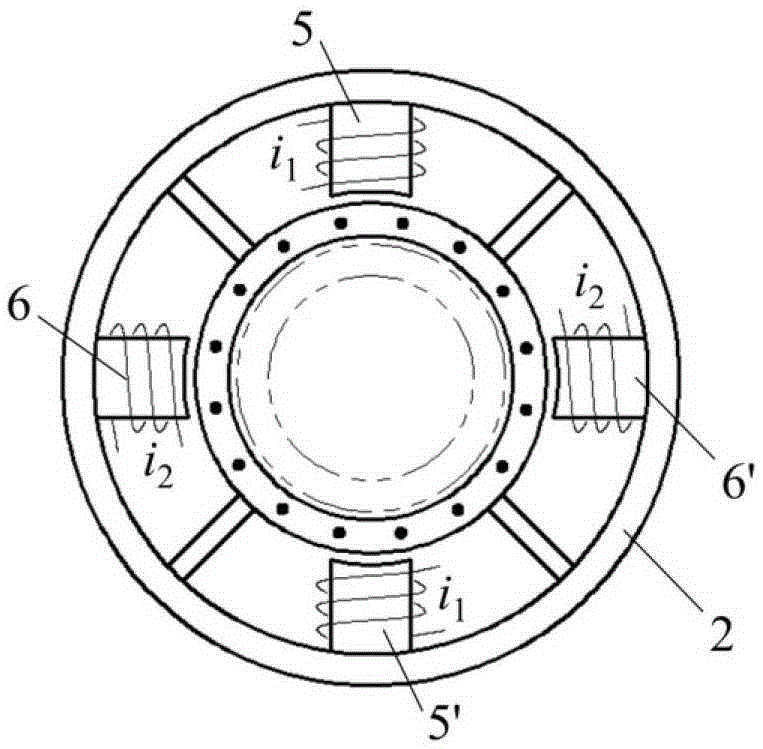

[0025] Such as image 3 As shown, two pairs of mutually perpendicular magnetizers are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com