Preparation method and application of a lithium-ion battery negative electrode material based on photovoltaic silicon waste

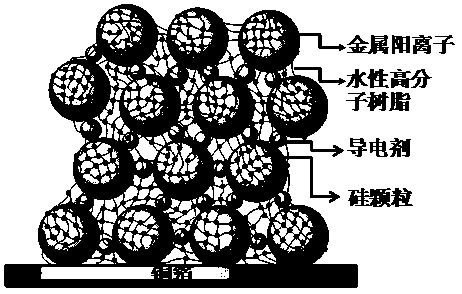

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor electronic conductivity, and achieve the effects of improving electronic conductivity, low price, and improving cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Weigh 500g of photovoltaic silicon waste (average particle size is 1 micron), first pass through dilute HCl and dilute HNO 3 were washed three times, and then placed in H 2 SO 4 +H 2 o 2 (3:1) to 100°C and hold for 3 hours. The samples after surface oxidation were washed three times with deionized water, ethanol and acetone respectively. After the cleaned materials are dried in an air environment of 100 degrees, they are placed in a tube furnace and heated at 600 degrees under an inert atmosphere for 3 hours to completely carbonize the residual organic matter on the surface.

[0037] (2) Weigh 100g of pre-treated photovoltaic silicon material, then weigh 1g of glucose and 1g of ferric nitrate, and grind the mixture of the three until uniformly dispersed; uniformly disperse the above mixture in a crucible or a porcelain boat, and place In the center of a closed tube furnace, the reaction is carried out in a mixed gas of argon and hydrogen, and the temperature i...

Embodiment 2

[0042] (1) Weigh 1000g of photovoltaic silicon waste (average particle size is 5 microns), first pass through dilute HCl and dilute HNO 3 Wash three times respectively, then place in concentrated nitric acid and heat to 120 degrees, and keep it for 1 hour. The samples after surface oxidation were washed three times with deionized water, ethanol and acetone respectively. After the cleaned materials are dried in an air environment of 200 degrees, they are placed in a tube furnace and heated at 800 degrees under an inert atmosphere for 6 hours to completely carbonize the residual organic matter on the surface.

[0043] (2) Weigh 200g of pre-treated photovoltaic silicon material, then weigh 10 g of sucrose and 2 g of nickel nitrate, and grind the mixture of the three until uniformly dispersed; uniformly disperse the above mixture in a crucible or a porcelain boat, and Placed in the center of a closed tube furnace, the reaction was carried out in a mixed gas of argon and hydrogen,...

Embodiment 3

[0048] (1) Weigh 1000g photovoltaic silicon waste (average particle size is 2 microns), first pass through dilute HCl and dilute HNO 3Wash three times respectively, then place in potassium dichromate solution and heat to 90 degrees, and keep it for 1 hour. The samples after surface oxidation were washed three times with deionized water, ethanol and acetone respectively. After the cleaned materials are dried in an air environment of 200 degrees, they are placed in a tube furnace and heated at 800 degrees under an inert atmosphere for 6 hours to completely carbonize the residual organic matter on the surface.

[0049] (2) Weigh 500g of pre-treated photovoltaic silicon material, then weigh 5 g of polymethyl methacrylate and 2.5 g of cobalt acetate, and grind the mixture of the three until uniformly dispersed; uniformly disperse the above mixture in a crucible or In a porcelain boat and placed in the center of a closed tube furnace, the reaction is carried out in a mixed gas of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com