Electric connector and plugging module thereof, and manufacturing method of plugging module

An electrical connector and electrical connection technology, which is applied to the components of the connection device, the structural connection and connection of the printed circuit, etc., can solve the problems of low efficiency, increase the cost of network connectors, unfavorable maintenance, etc., and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

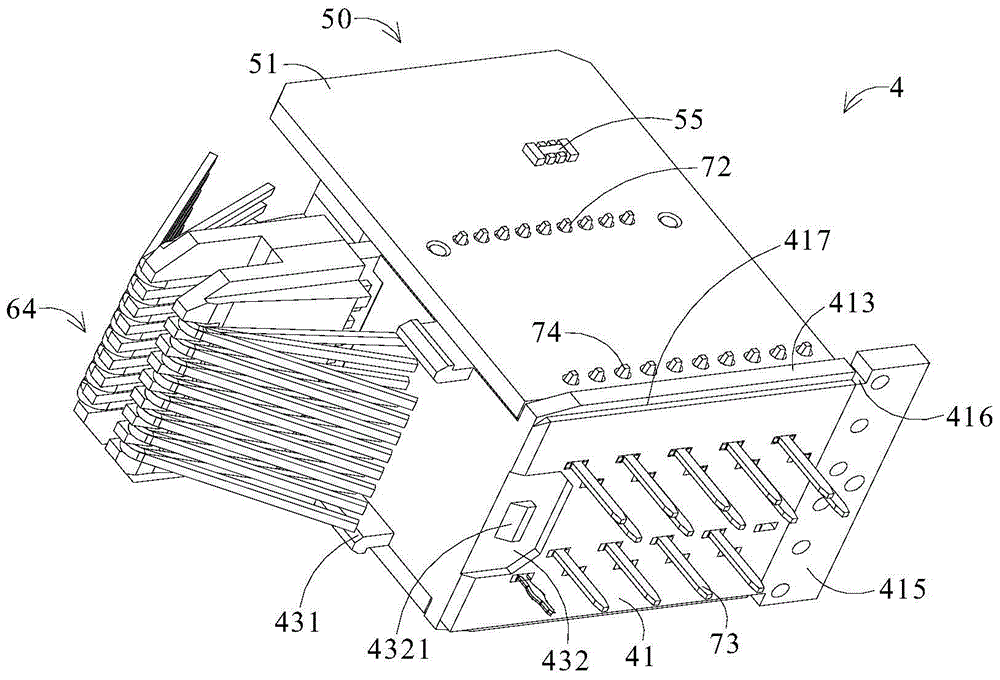

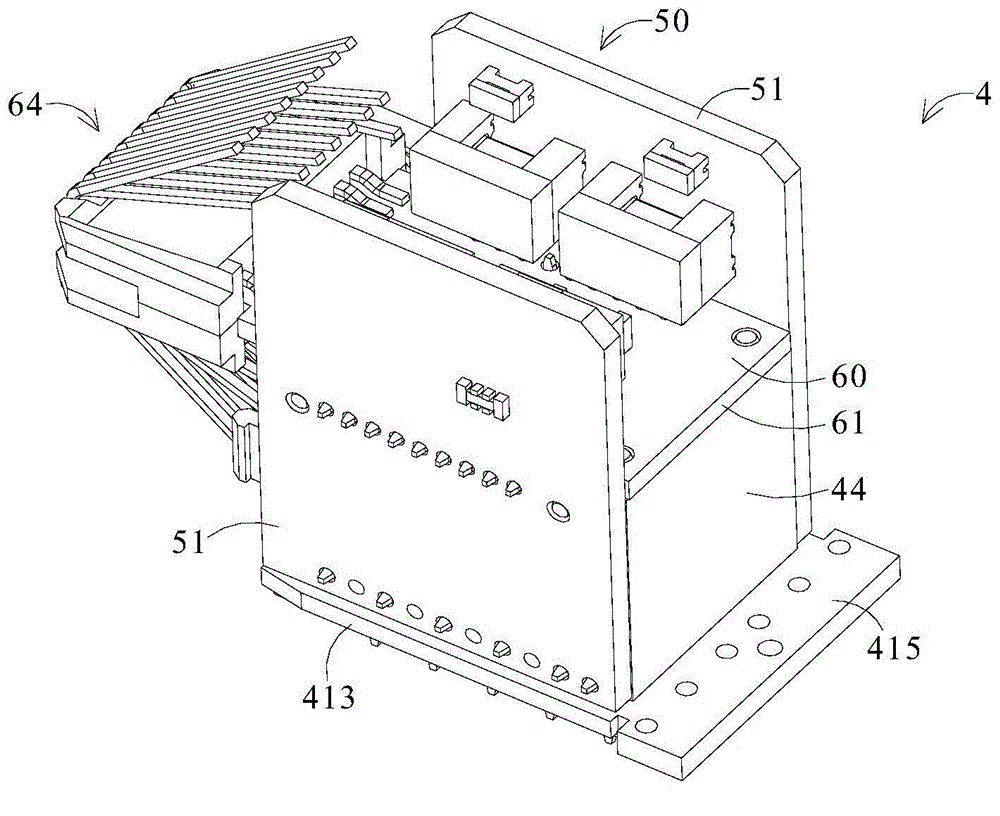

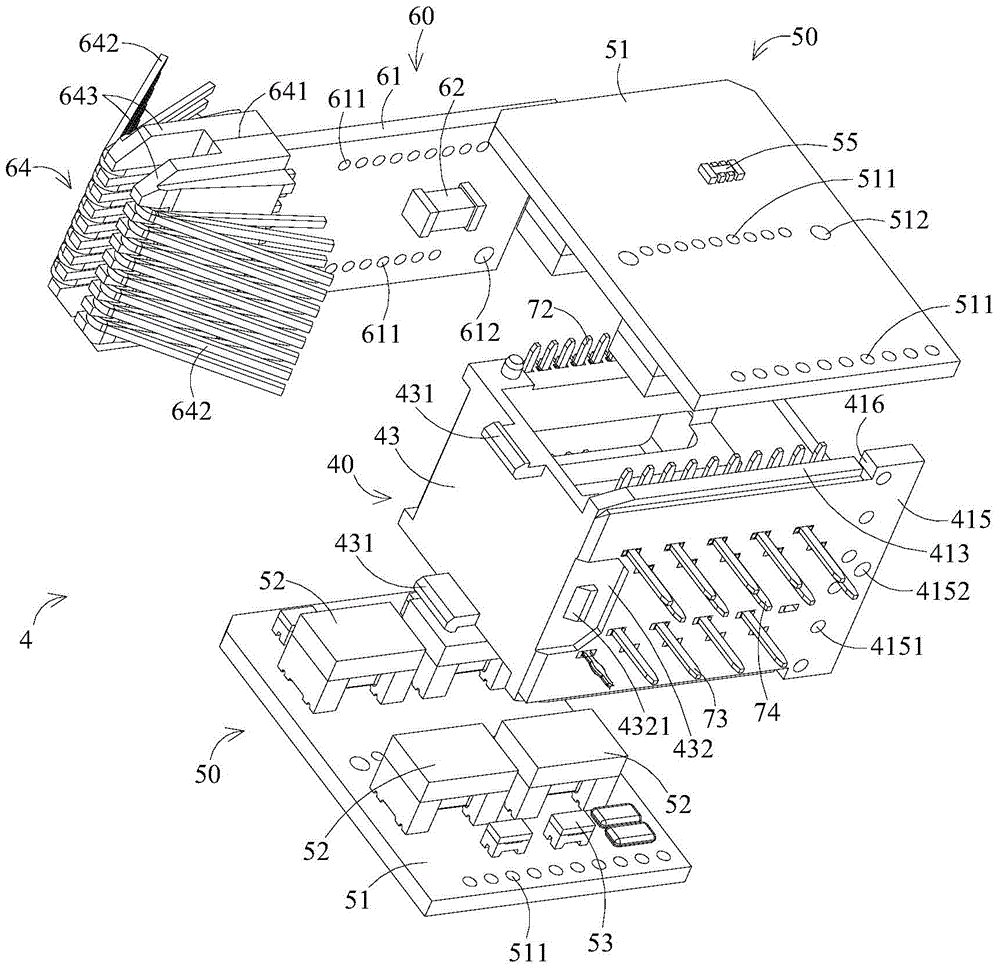

[0059] see Figure 1 to Figure 6 . The first embodiment of the plug-in module 4 of the present invention includes a base 40, an input unit 50, an output unit 60, an output terminal 64, several input terminals and several transfer terminals.

[0060] see Figure 4 and Figure 5 . The base 40 includes a bottom plate 41 and a top plate 42 oppositely arranged, a front plate 43 connecting the front ends of the bottom plate 41 and the top plate 42 , and a rear plate 44 connecting the rear ends of the bottom plate 41 and the top plate 42 . In the first embodiment, the base plate 41, the top plate 42, the front plate 43 and the rear plate 44 jointly form a rectangular parallelepiped frame. Frames other shapes, such as trapezoids. In addition, in other embodiments, the rear plate 44 may not be provided; further, the front plate 43 may also be replaced by a connecting plate connected to the bottom plate 41 and the top plate 42 .

[0061] A central through hole 420 is defined in th...

Embodiment approach 2

[0077] see Figure 7 and Figure 8 . The difference between the second embodiment of the plug-in module 4 of the present invention and the first embodiment is that the bottom plate 41 of the base 40 does not have the rear extension arm 415 .

[0078] Other structures of the second embodiment of the plug-in module 4 of the present invention are basically the same as those of the first embodiment, and will not be repeated here.

[0079] Embodiment 1 of electrical connector

[0080] see Figure 9 to Figure 15 . The first embodiment of the electrical connector of the present invention is a 2XN electrical connector (with upper and lower rows of docking sockets), which includes an insulating body 20 , a housing outside the insulating body 20 , a plug-in module 4 and a display device.

[0081] see Figure 11 to Figure 14 . The insulating body 20 is in the shape of a cuboid and has opposite top walls 21 and bottom walls 22 , opposite side walls 23 and a front wall 24 . The ins...

Embodiment approach

[0101] An embodiment of a manufacturing method of an insert module, comprising the following steps:

[0102] providing a base on which several input terminals and several transfer terminals are fixed;

[0103] Making an input unit, which includes at least one input circuit board, at least one channel is arranged on each input circuit board, and each channel includes a transformer electrically connected to the input circuit board;

[0104] Making an output unit, which includes an output circuit board;

[0105] The at least one input circuit board is vertically arranged on the base, and the input circuit board is electrically connected to one end of the input terminal;

[0106] The output circuit board is horizontally arranged on the base, and the output circuit board is electrically connected to the input circuit board through the transfer terminal; and

[0107] An output terminal is provided, which is fixed and electrically connected to the output circuit board.

[0108] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com