Automatic hoop bending machine for straight steel bar

A hoop bending machine and steel bar technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of not being suitable for processing straight steel bars, lack of material calculation mechanism, lack of basis for calculating the length of materials used and the quantity of finished products, etc. , to achieve the effect of simple structure, sensitive action, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are further described in detail below.

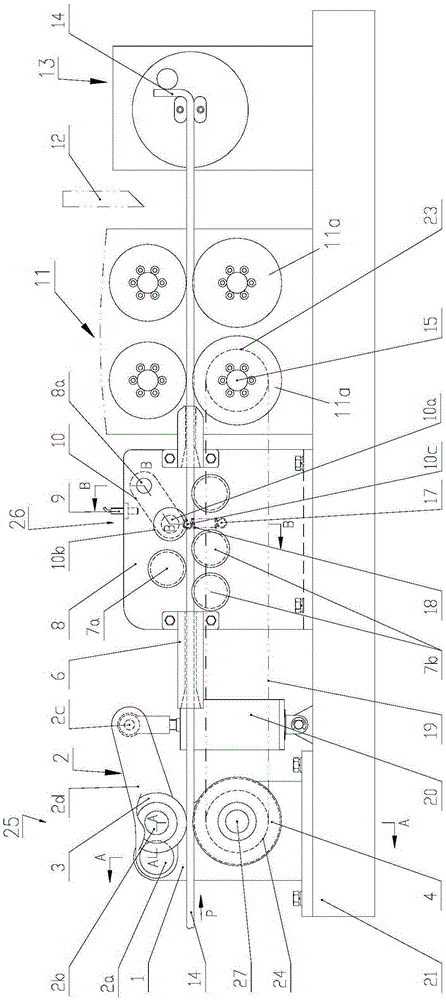

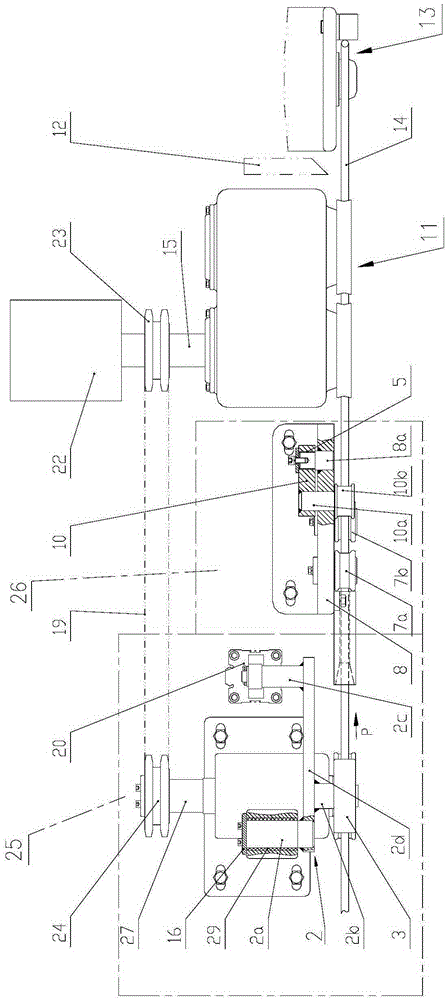

[0020] As shown in the figure, the present invention discloses an automatic hoop bending machine for straight steel bars. The automatic hoop bending machine for straight steel bars includes: on the frame 21, a traction mechanism 11, a shearing mechanism, Cutting mechanism 12 and bending mechanism 13.

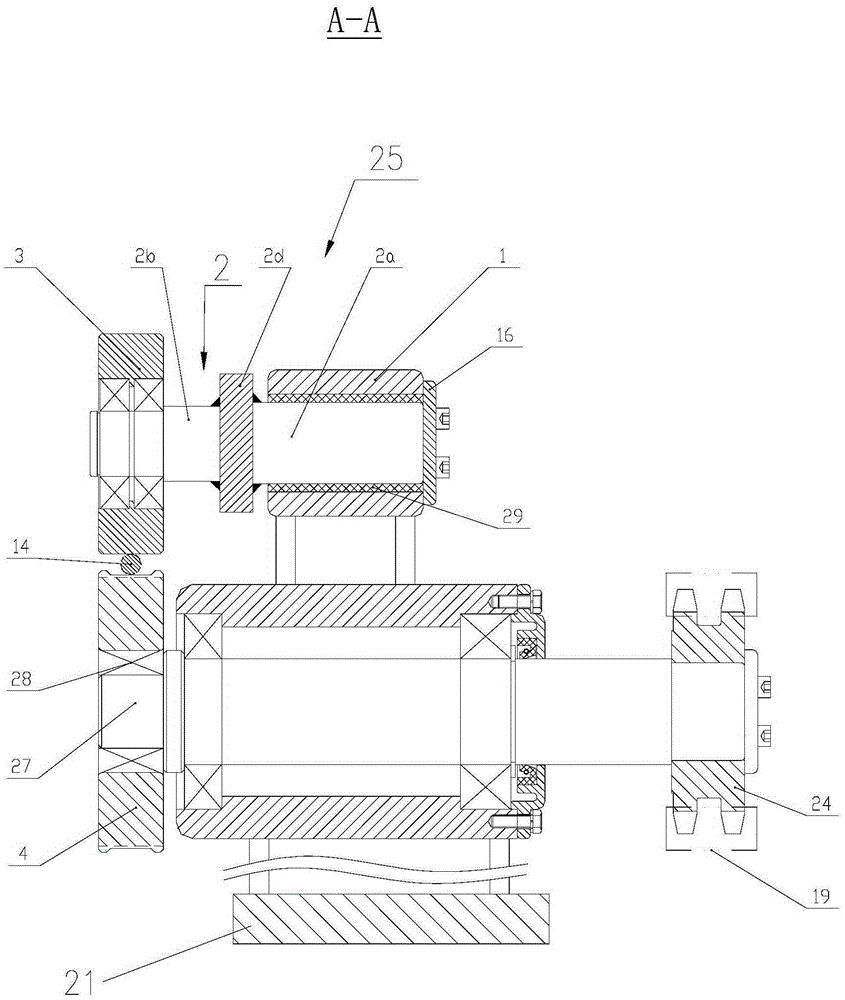

[0021] Such as figure 1 , figure 2 The present invention shown also includes the feeding mechanism 25 that is arranged at the inlet end of the frame 21 before the traction mechanism 11, and the feeding mechanism 25 includes: the lower feeding wheel 4 positioned below the straight bar 14 and connected to the rotating power source, On the straight steel bar 14 and connect the upper feeding wheel 3 of the upper pinch roller swing arm 2.

[0022] The upper pressure roller swing arm 2 includes: a connecting plate 2d, a connecting shaft 2c and a hinged shaft 2a protrude from both ends of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com