A kind of preparation method of fe3o4/bi core-shell nanorod

A nanorod, core-shell technology, applied in metal processing equipment, coating, transportation and packaging, etc., to achieve high quality, good biocompatibility, good paramagnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

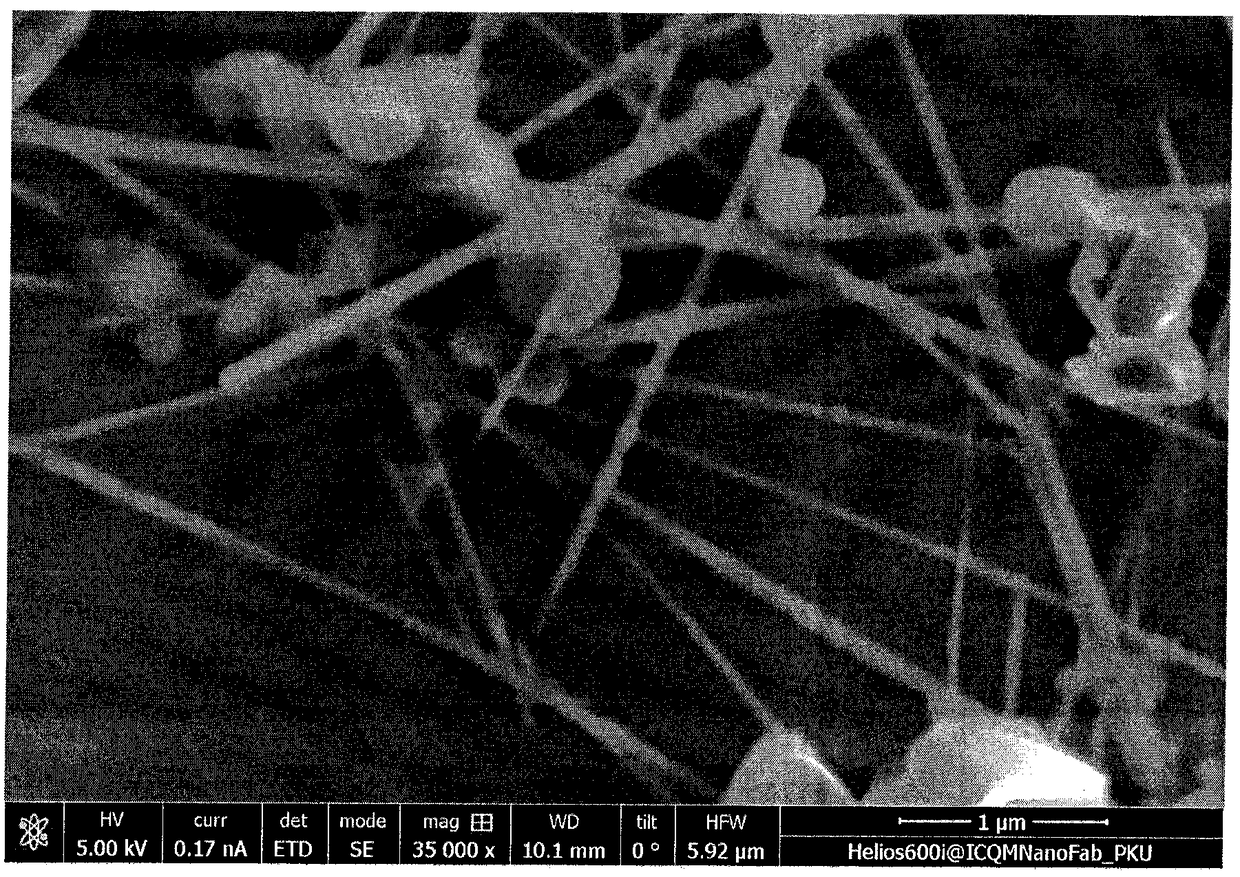

[0020] see figure 1 , in the embodiment of the present invention, a kind of Fe 3 o 4 / The preparation method of Bi core-shell nanorod, it specifically comprises the following steps:

[0021] (1) 0.946g of FeCl 3 ·H 2 O and 0.497g Na 2 SO 4 Mix with 70mL of distilled water, leave at room temperature for 15 minutes, then transfer the mixed solution to a Teflon-lined stainless steel autoclave with a titanium foil at the bottom, and heat at 165°C for 7 hours;

[0022] (2) After cooling to room temperature, the obtained Fe 3 o 4 The nanorods were taken out and soaked in 200mL aqueous solution containing 0.5g glucose for 36 hours;

[0023] (3) Fe 3 o 4 The nanorods were dried at 60°C and annealed at 550°C for 3 hours in an argon flow;

[0024] (4) Fe that will be prepared 3 o 4 Nanorods were placed in 0.01 mol of analytically pure Bi(NO 3 ) 3 and excess hydrazine hydrate mixed solution, then transferred to a stainless steel autoclave, and heated at 100°C for 10 hours;...

Embodiment 2

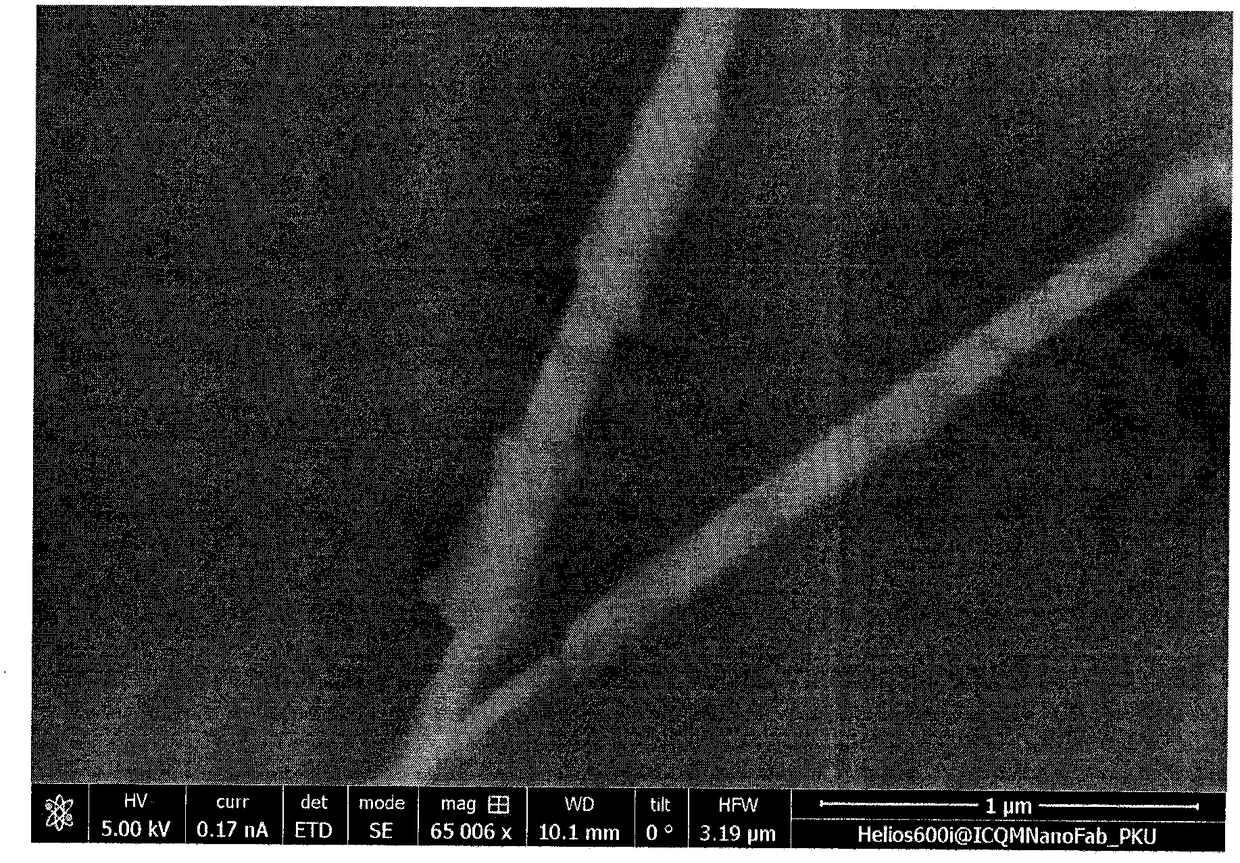

[0029] see figure 2 , in the embodiment of the present invention, a Fe 3 o 4 / The preparation method of Bi core-shell nanorod, it specifically comprises the following steps:

[0030] (1) 0.946g FeCl 3 ·H 2 O and 0.497g Na 2 SO 4 Mix with 70 mL of distilled water and let stand at room temperature for 15 minutes. Then the mixed solution was transferred to a Teflon-lined stainless steel autoclave with a titanium foil at the bottom, and heated at 165°C for 7 hours;

[0031] (2) After cooling to room temperature, the obtained Fe 3 o 4 The nanorods were taken out and soaked in 200mL aqueous solution containing 0.5g glucose for 36 hours;

[0032] (3) Fe 3 o 4 The nanorods were dried at 60°C and annealed at 550°C for 3 hours in an argon flow;

[0033] (4) Fe that will be prepared 3 o 4 The nanorods were put into 0.03mol of analytically pure Bi(NO 3 ) 3 and excess hydrazine hydrate mixed solution, then transferred to a stainless steel autoclave, heated at 100°C for 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com