Positioning and clamping device

A technology of positioning, clamping, and included angle, which is applied to gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems of inability to eliminate the positioning error of the matching gap, low repeated positioning accuracy of the clamping device, and high cost of the grinding process. Achieve the effect of ensuring uniform radial expansion, ensuring processing quality, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

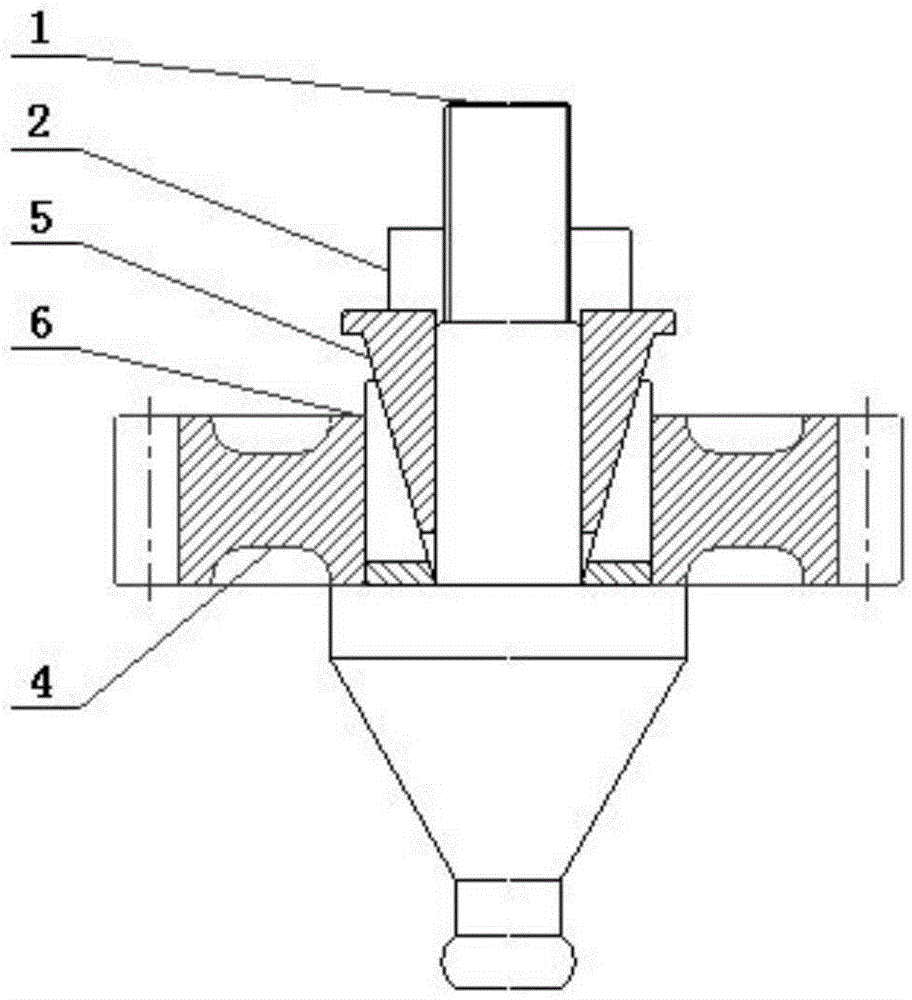

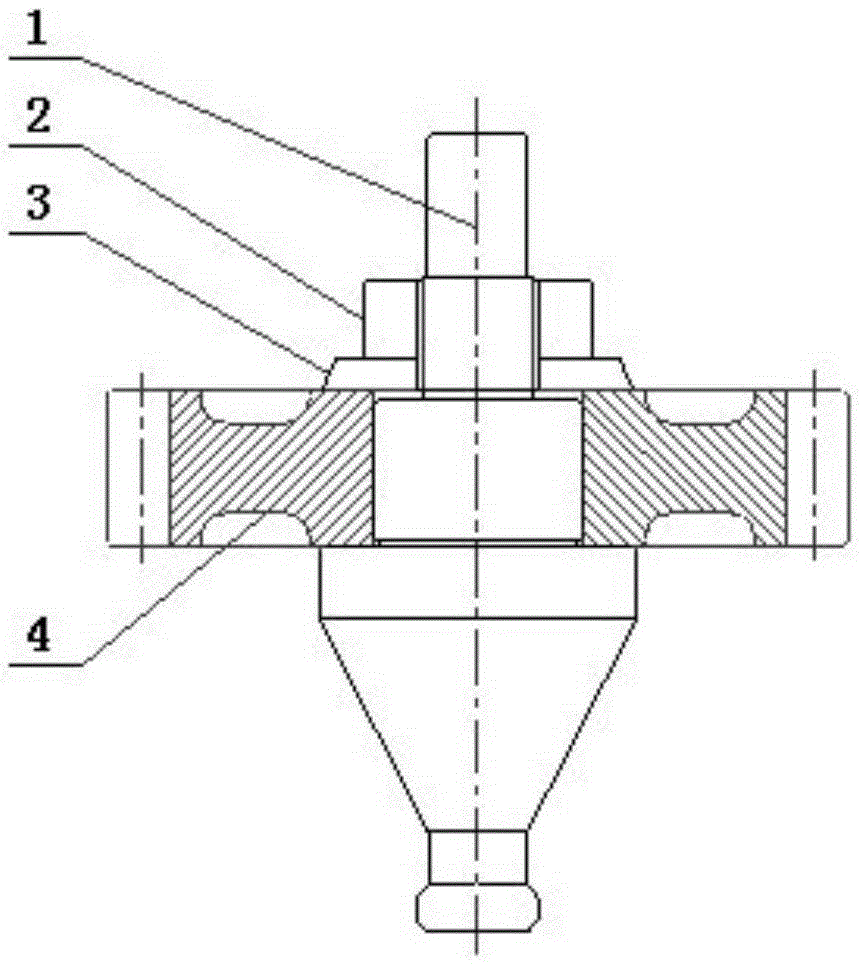

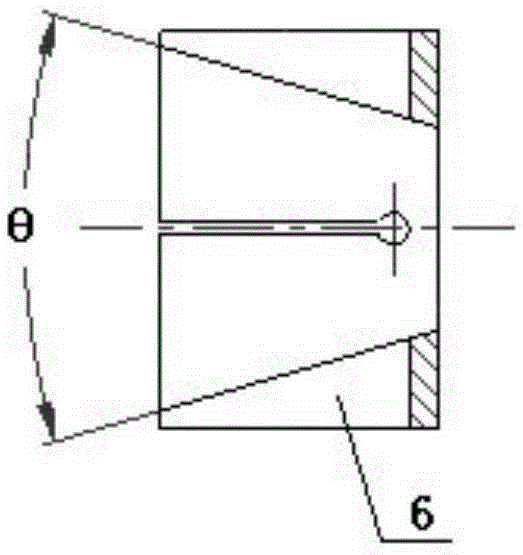

[0035] Referring to the accompanying drawings, the present invention is realized in the following way: a positioning and clamping device, which includes a clamp body 1, a compression nut 2, a compression sleeve 5 and an expansion sleeve 6; The stepped shaft of the screw thread 11, the compression sleeve 5 is a hollow cone; the expansion sleeve 6 is a cylindrical body whose inner hole is axially tapered, and the wall of the expansion sleeve 6 is provided with two or two Expansion grooves A61 evenly distributed above the strip; the expansion sleeve 6 passes through the external thread 11 end of the clamp body 1 and clings to the step surface 12, and the workpiece 4 passes through the outer circle of the expansion sleeve 6 and clings to the step surface of the clamp body 1 12. The compression sleeve 5 passes through the end of the external thread 11 of the clamp body 1 and is installed in the taper hole of the expansion sleeve 6. The compression nut 2 is connected to the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com