Locating device for welding guide pipe connector at any angle

A technology of conduit joints and positioning devices, which is applied in the field of material engineering, can solve the problems of increasing the development cycle of pipeline systems and waste of tooling, and achieve the effects of saving production preparation cycles, accurate positioning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

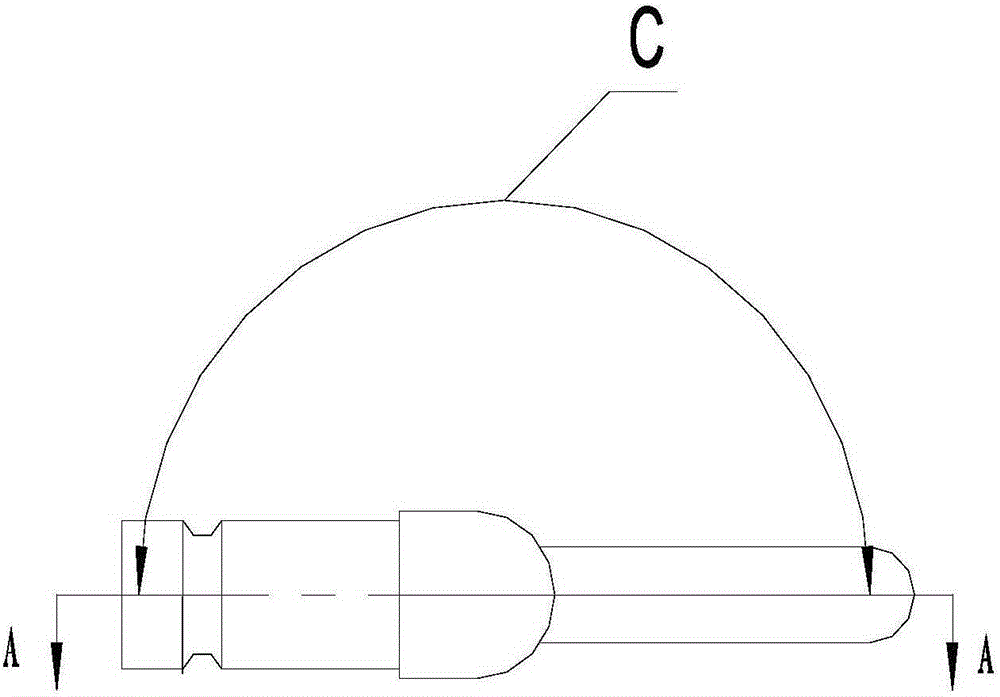

Image

Examples

Embodiment Construction

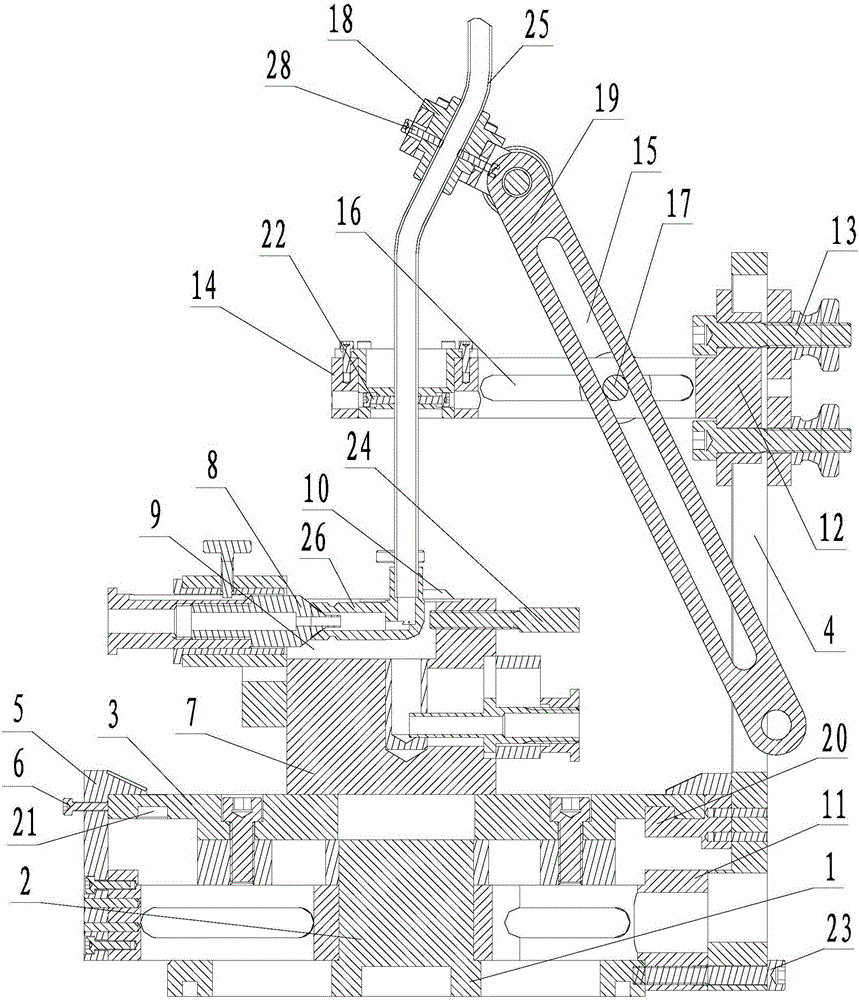

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

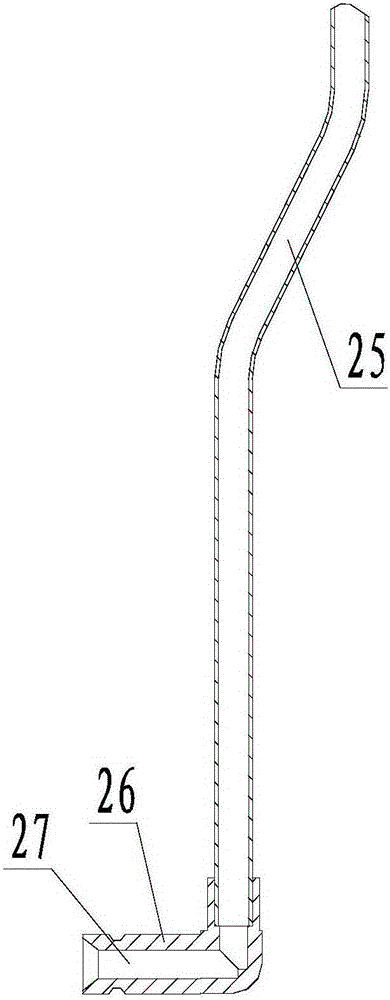

[0015] Such as image 3 As shown, a positioning device for the welding of conduit joints at any angle, including a base 1 with a shaft 2 on the upper part and a moving support arm 19, on which an angle disc 3 is fixed; on the shaft 2 below the angle disc 3, a rotating Block 11, the rotating block 11 can rotate around the shaft 2, on the rotating block 11, a rotating support arm 4 is fixed along the vertical direction; on the rotating block 11, an angle indicating block 5 is also fixed, and the angle indicating block 5 and Corresponding to the angle plate 3, the rotating support arm 4, the rotating block 11 and the angle indicating block 5 can rotate coaxially, and the first locking screw 6 is arranged on the angle indicating block 5, and the inner end of the first locking screw 6 is connected to the The angle plate 3 is in contact; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com