Preparation device for chopped glue-dipped fibers

A preparation device and fiber technology, which is applied in the field of chopped fiber preparation devices, can solve the problems of large fiber length error, fiber bending, and low cutting efficiency, and achieve the effects of preventing sticking and rolling, reducing contact area, and saving occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

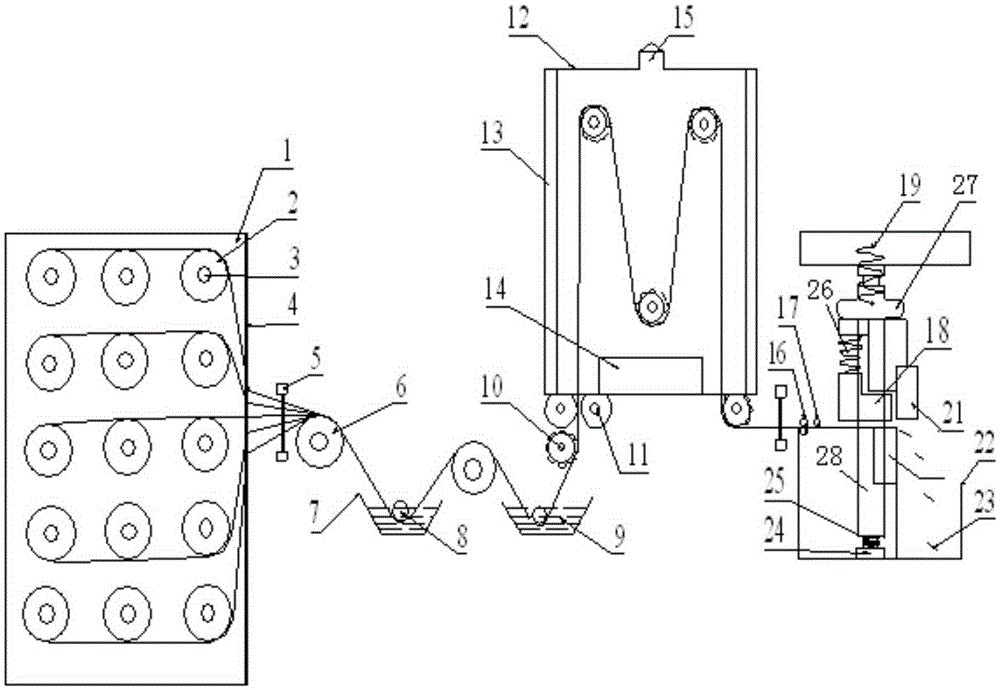

[0039] The following is attached Figure 1-4 Preferred embodiments of the present invention will be described.

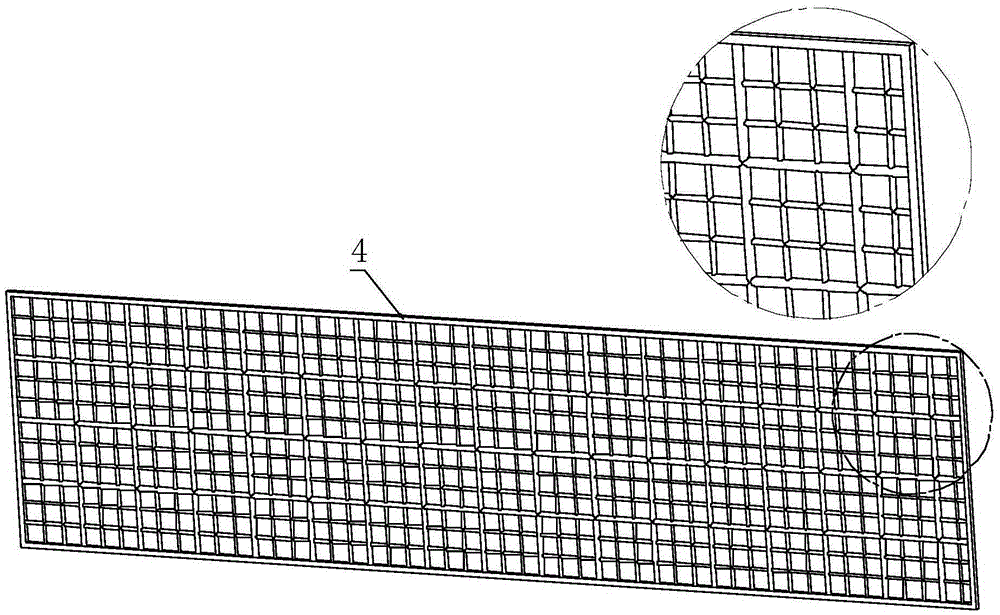

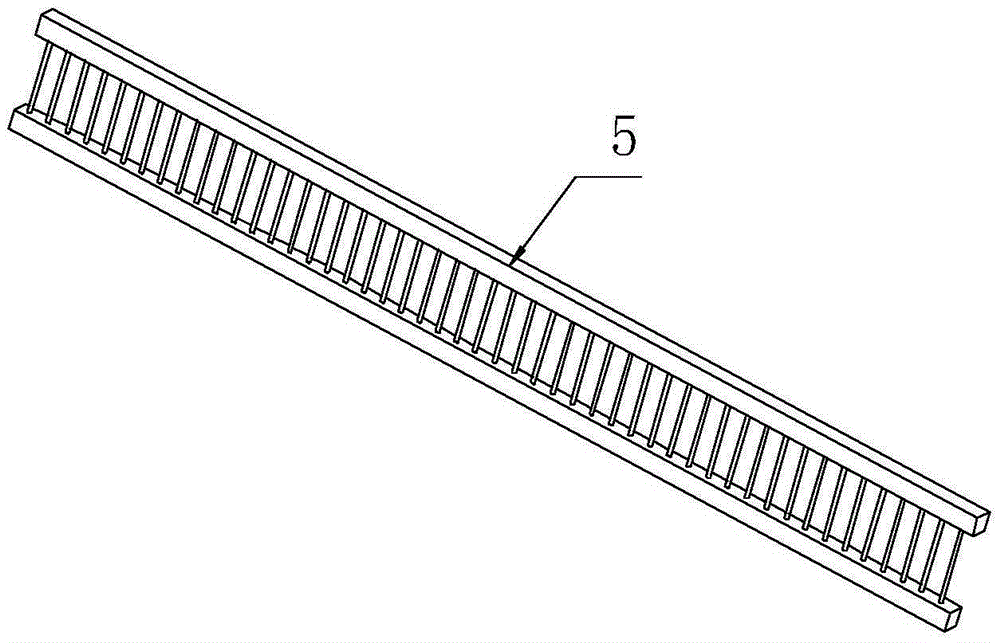

[0040] like figure 1 As shown, the chopped fiber dipped fiber preparation device of the present invention includes a fiber coil placement unit, a limiting plate, a dipping guide part, a dipping unit, a glue extrusion guide part, a glue extrusion unit, A drying unit, a cutting guide and a cutting unit. Among them, the fiber roll fixing frame adopts two back-to-back placement racks, on which multiple fiber rolls can be arranged and placed (each row of fiber rolls can not be placed on the same level or the method of inversion can be used to ensure that the fiber bundles will not be entangled with each other), Each fiber reel center has reverse tension counterweight, the fiber reel is placed on the rotating shaft of the fixed frame and 4 fiber reels are placed on the same horizontal plane. Both ends of the fiber roll fixing frame are installed with dense "Tianzi" smo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap