Composite asphalt modifier as well as preparation method and application method of composite asphalt modifier

A technology of composite asphalt, application method, applied in building components, building insulation materials, construction, etc., can solve the problems of large amount of polymer, high temperature rigidity, low temperature flexibility, unsatisfactory temperature sensitivity, unstable heat storage, etc., to achieve softening The effect of no point reduction, good compatibility, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Base asphalt: 985 grams of 70# heavy traffic asphalt produced by Zhenhai Refinery;

[0039] 15 grams of composite asphalt modifier of the present invention;

[0040] Fully mix and melt 15 grams of the composite asphalt modifier of the present invention and base asphalt at 170-200°C for about 100 minutes to make a modified asphalt composition; the modification results are as follows:

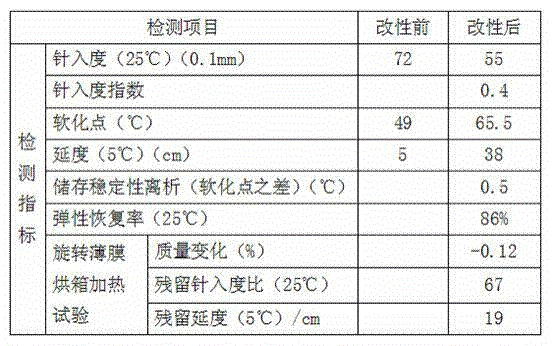

[0041]

[0042] It can be seen from the above table that by adding the composite asphalt modifier of the present invention alone, the penetration and softening point of the asphalt are greatly improved, and the ductility (5°C) is slightly increased, which shows that the high temperature stability and viscosity of the asphalt are significantly improved. Crack resistance improved slightly.

Embodiment 2

[0044] Base asphalt: 950 grams of 70# heavy traffic asphalt produced by Zhenhai Refinery;

[0045] Compatibilizer: 10 grams of furfural extracted oil (aromatic content: above 80%);

[0046] Polymer: 30 grams of YH791-H type SBS produced by Yuehua;

[0047] Cross-linking agent: 0.05 g of sulfur powder;

[0048] 10 grams of composite asphalt modifier of the present invention;

[0049] Heat 950 grams of base asphalt to 150°C, add 10 grams of compatibilizer, 30 grams of polymer, 0.05 grams of cross-linked body, and 10 grams of composite asphalt modifier of the present invention at 150-200°C, fully Mix and melt for 250-300 minutes to make a modified asphalt composition. The modification results are as follows:

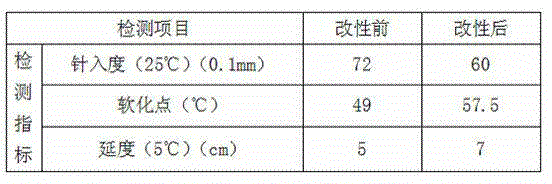

[0050]

[0051] It can be seen from the above table that the asphalt compound modified by SBS and the composite asphalt modifier of the present invention can greatly improve the high and low temperature performance and anti-aging performance of the asphalt under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com