Photoelectric corrective mechanism adopting rust-proof electric cylinder for coil slitting machine

A photoelectric deviation rectification and electric cylinder technology, applied in the field of deviation rectification devices, can solve the problems of poor deviation rectification work efficiency, failure to detect coil deviation in time, and low deviation rectification accuracy, and achieve high installation work efficiency, deviation rectification work efficiency, and deviation rectification accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

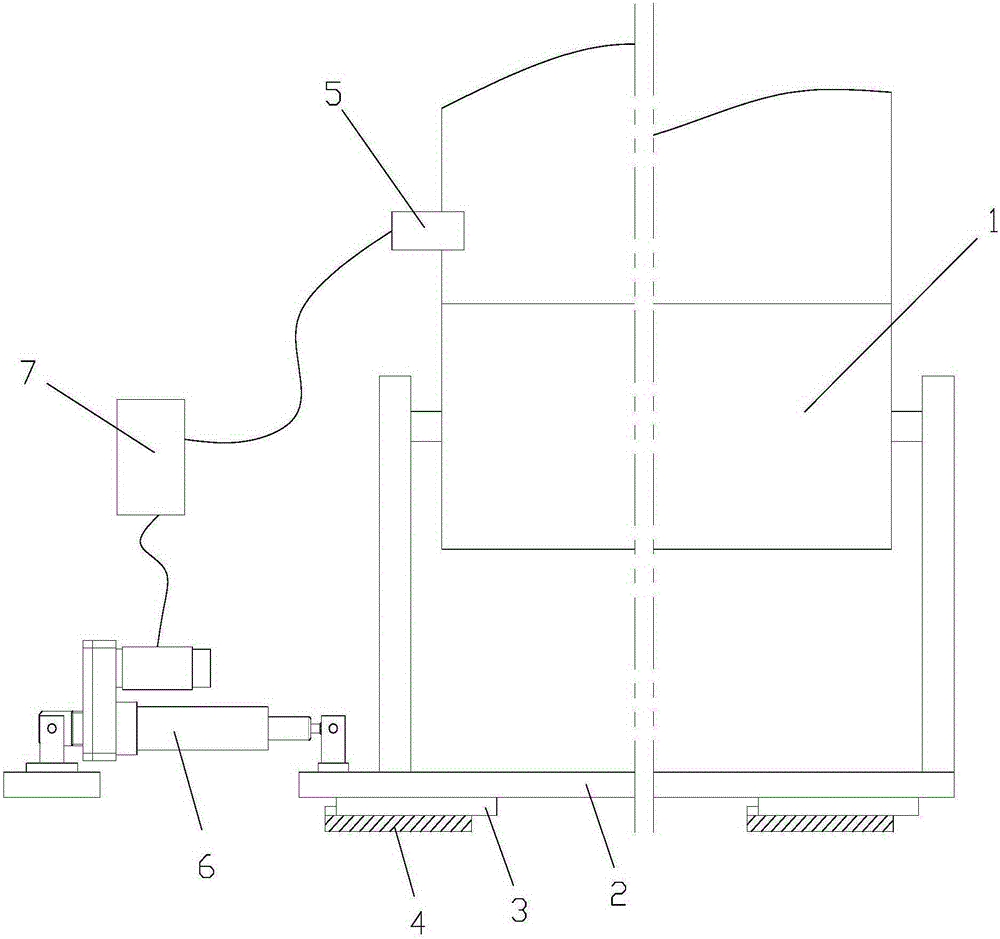

[0020] As shown in the figure, this embodiment adopts the anti-rust electric cylinder photoelectric correction mechanism of the coil slitting machine, including the unwinding roller 1, the bracket 2 supporting the unwinding roller, the guide rail 3 connected with the bracket, and the guide rail slidingly matched. The guide rail seat 4 also includes a photoelectric sensor 5 arranged on the edge of the coil to detect the deviation of the edge of the coil, an electric cylinder 6 for driving the bracket to move, and a controller 7 for controlling the electric cylinder, and the photoelectric sensor is electrically connected to the controller;

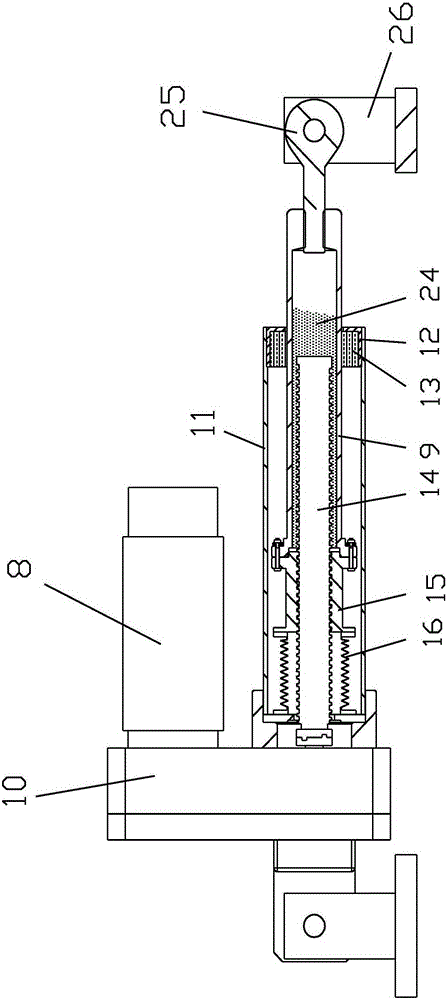

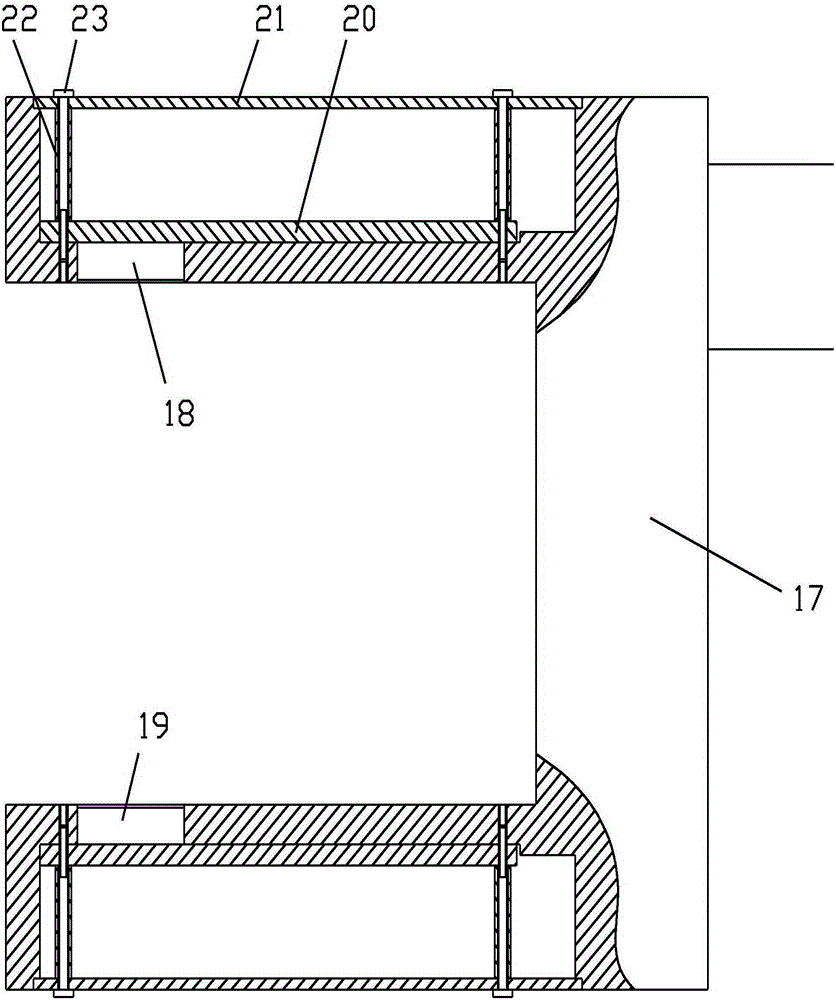

[0021] The electric cylinder includes a motor 8, a sliding sleeve 9 connected with a bracket, a screw mechanism for pushing the sliding sleeve to reciprocate linearly, a reducer 10 connecting the motor and the screw me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com