Generator Mounting Kits for Engines

A technology for installing components and generators, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of limited structural strength and bearing capacity, damage, looseness, etc., achieve stable and reliable connection relations, improve the overall structural strength, and prevent shaft to the effect of channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

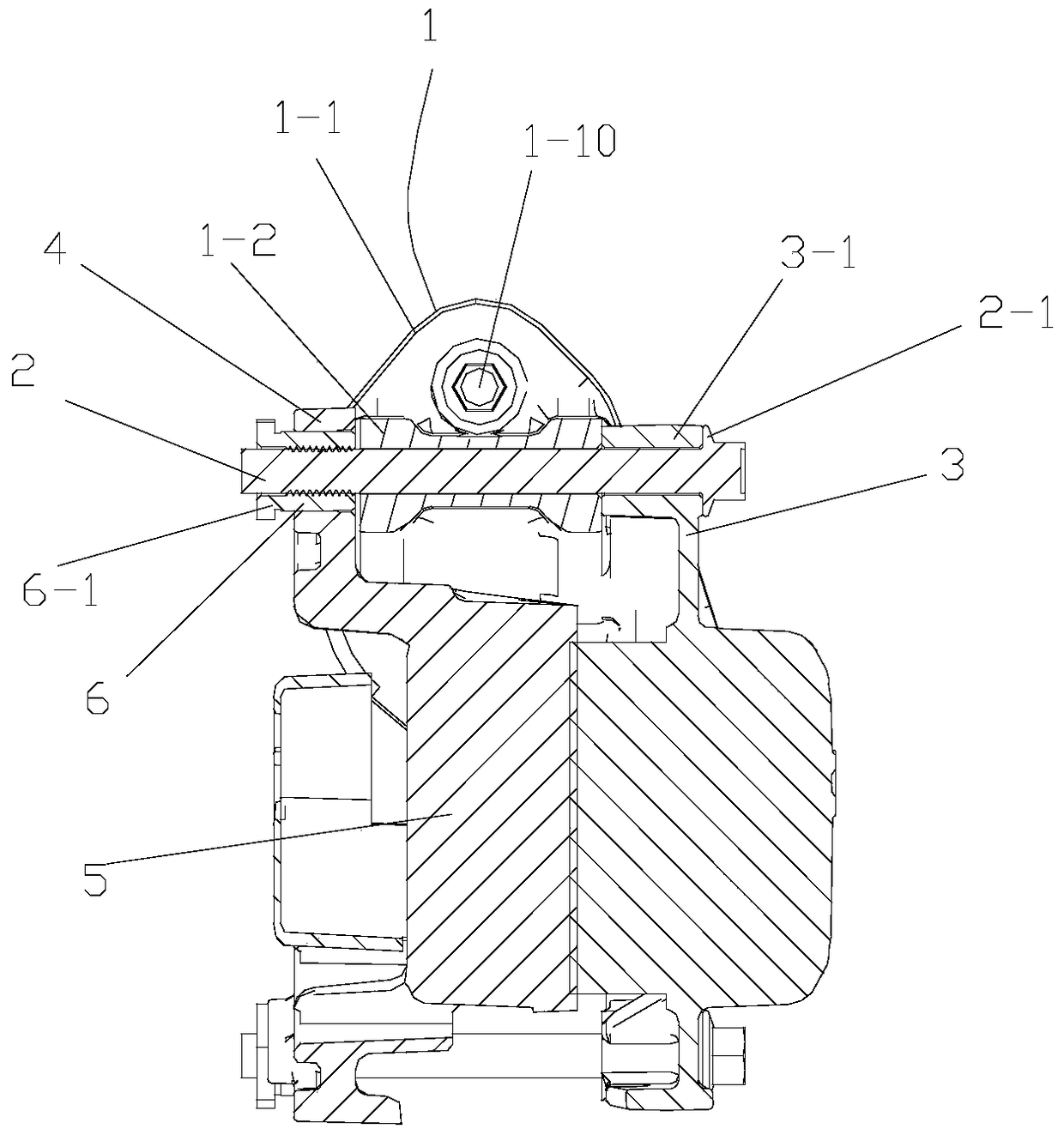

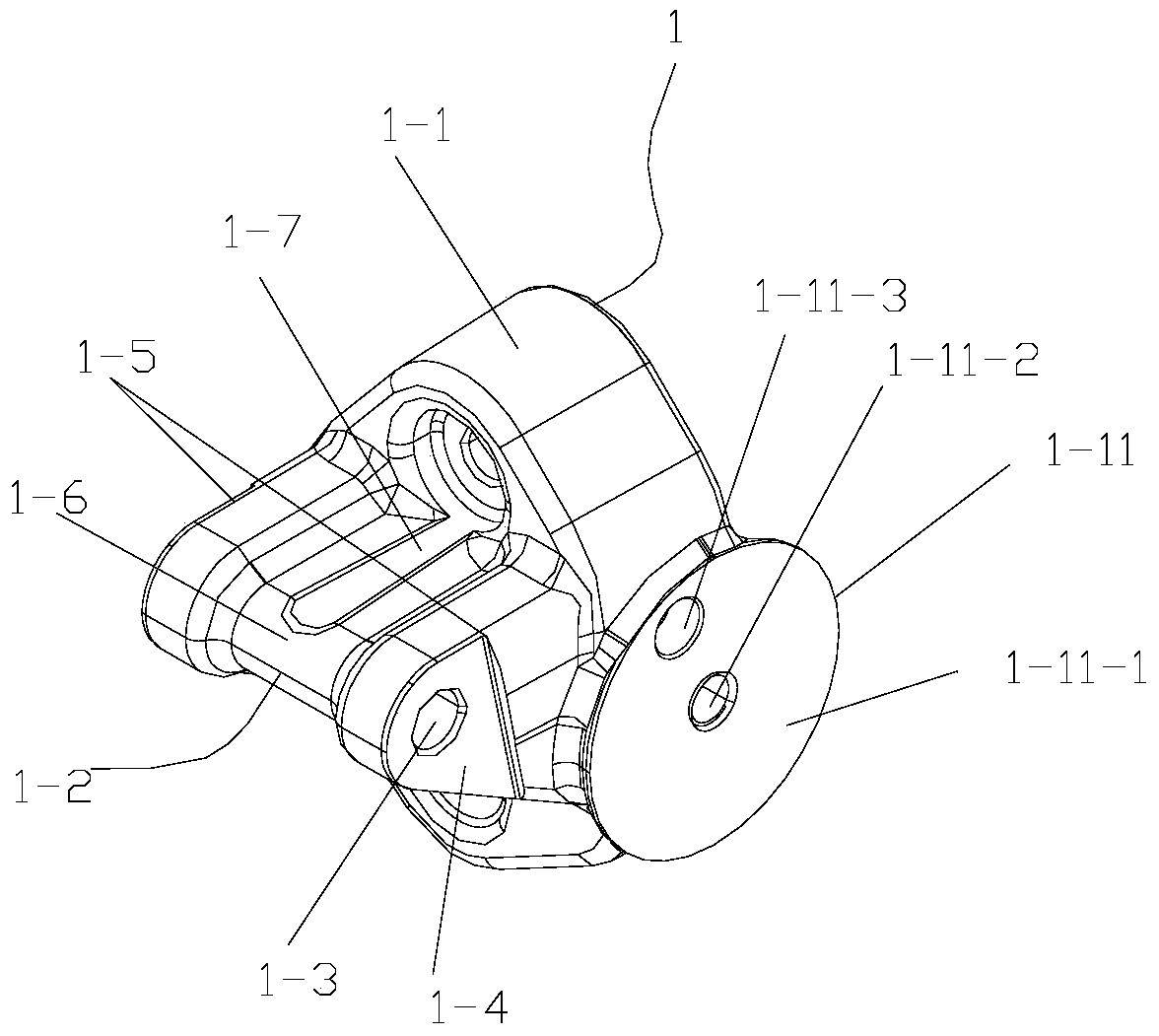

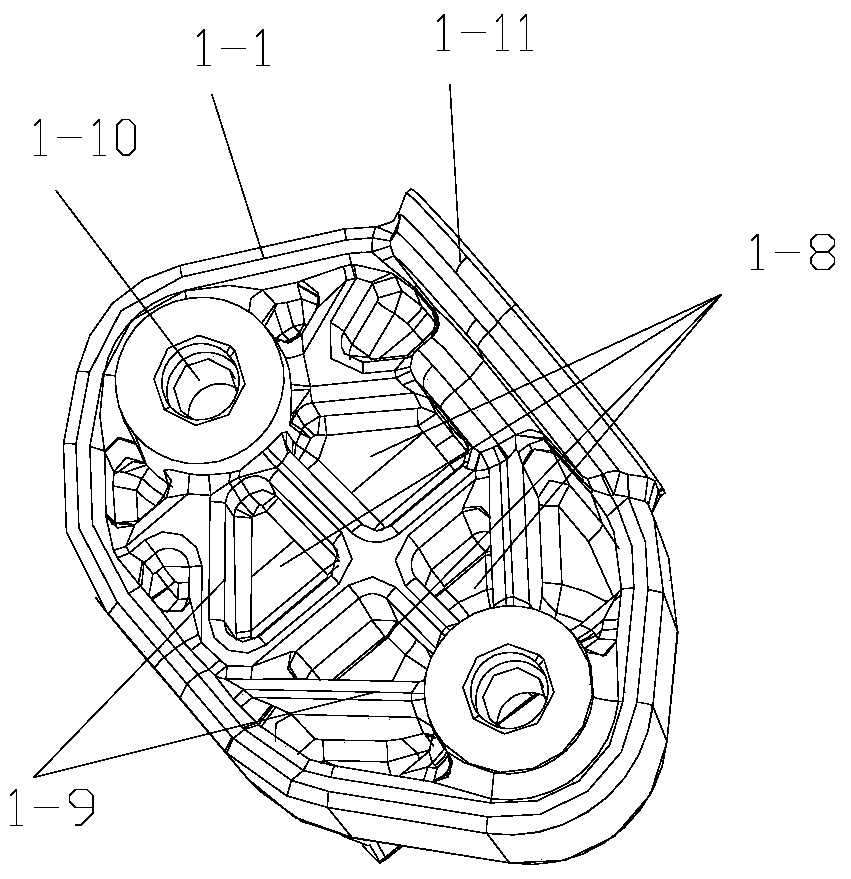

[0023] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a three-dimensional view of the generator bracket in the present invention, image 3 It is the rear view of the generator bracket in the present invention, Figure 4 It is a plane view of the generator bracket in the present invention, Figure 5 for Figure 4 right elevation, Figure 6 for Figure 4 Left side view, as shown in the figure: the engine generator installation assembly of the present embodiment includes a generator bracket 1, a connector 2 and connecting lugs formed on the outer casing of the generator 5 (connecting lugs are shown in the figure 3 and connecting lugs 4); the generator bracket 1 includes a bracket body 1-1 that can be fixed on the cylinder block of the engine and a mounting protrusion that is integrally formed with the bracket body 1-1 and extends away from the cylinder body. Platform 1-2, a set of holes 1-3 is formed through the length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com