High-performance airfoil for fan

A high-performance, airfoil-shaped technology, applied in the components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc., can solve problems such as poor matching, and achieve excellent matching and energy efficiency. High value, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

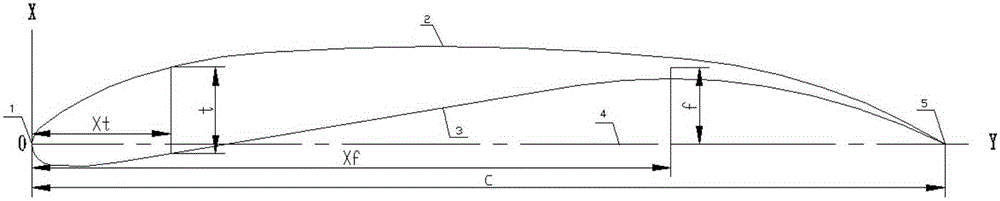

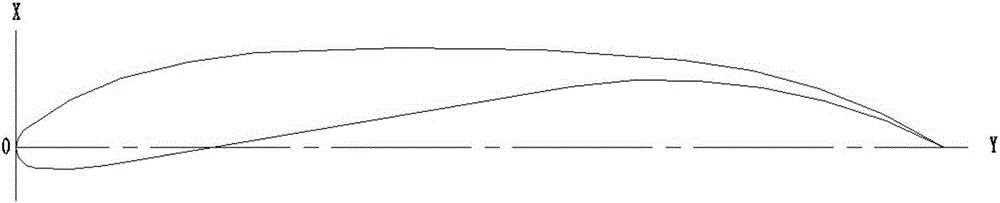

[0065] The accompanying drawings disclose an embodiment of the present invention without limitation, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

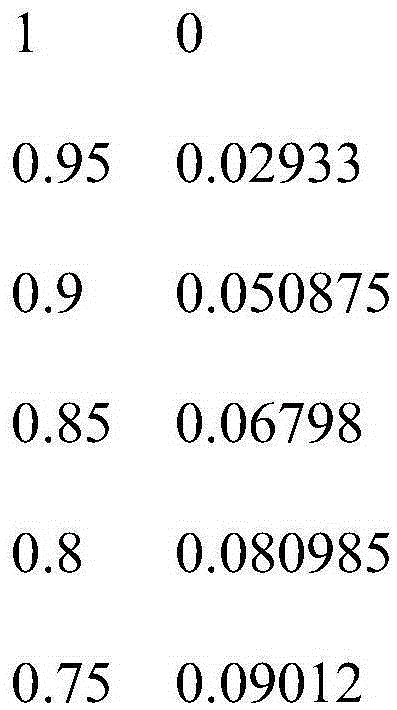

[0066] The design principle of the airfoil for a high-performance fan described in the present invention is: firstly, in combination with the working conditions of the low-speed fan, the aerodynamic analysis technology of the aviation industry is used to design a high-performance airfoil that matches well with the actual working conditions of the fan. Fan-specific airfoil. Since the main performance of the airfoil depends largely on its upper and lower surfaces or the shape of the middle arc, especially the low-speed airfoil, so by further studying the law of the upper and lower surfaces of the designed high-performance fan-specific airfoil The characteristics, the distribution law of the upper and lower surfaces of the high-performance airfoil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com